A grinding soybean milk machine and its automatic cleaning method

An automatic cleaning and soymilk maker technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. water flow and other issues, to save water resources and eliminate cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

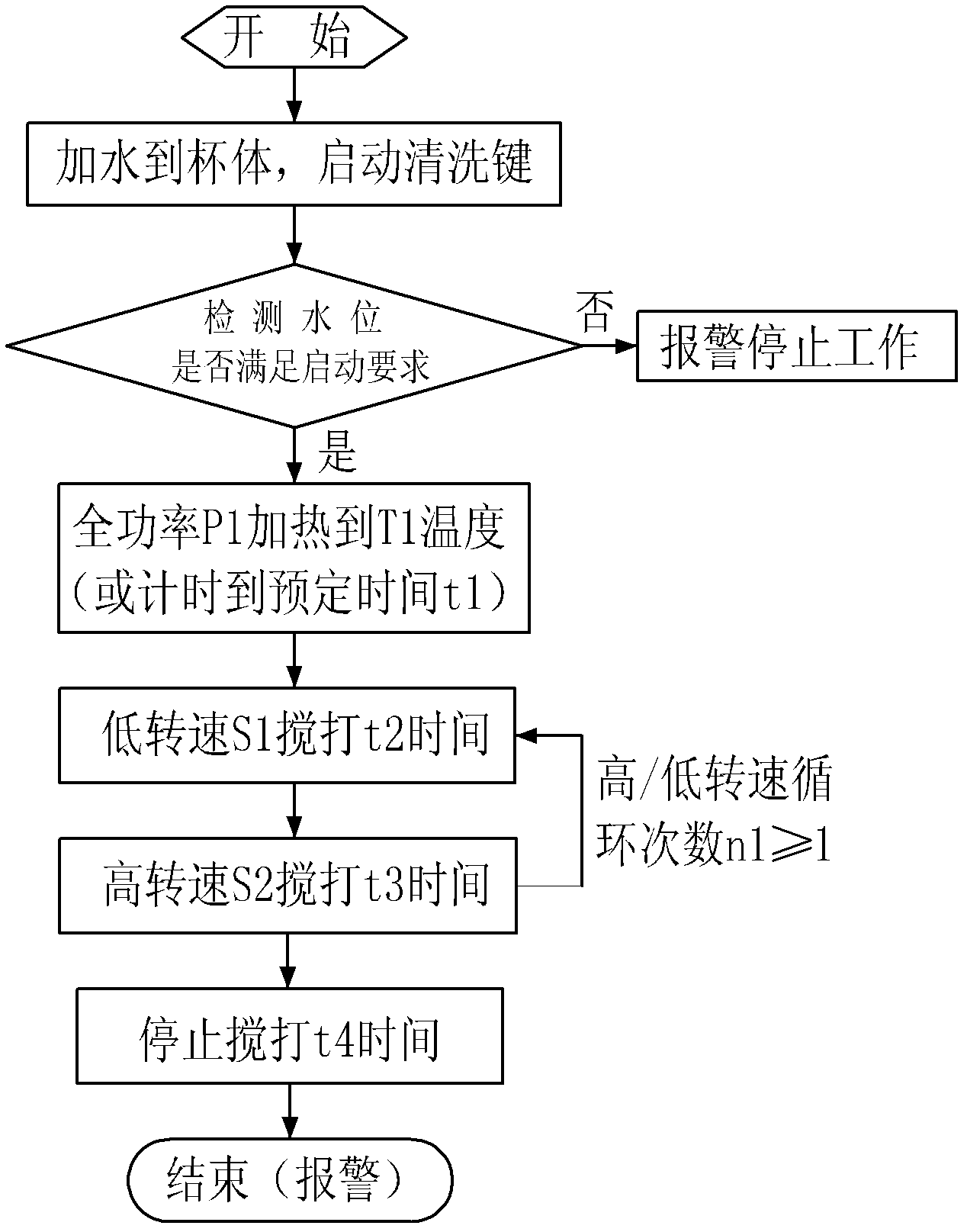

Embodiment 1

[0041] See attached figure 1 , attached Figure 6-8 , a grinding soymilk machine, a processor 81, a detection unit 83, a grinding unit 4, a main control circuit 8 of a heating unit, a machine head 1 accommodating the main control circuit 8, and a slurry container 2 connected to the machine head 1, containing The slurry container 2 is provided with a movable grinding head 41 connected to the motor shaft in the machine head and a static grinding head 42 matched with the moving grinding head 41. The space forms a concentrated water flow for cleaning.

[0042] The moving grinding head 41 and the static grinding head 42 are all provided with grinding teeth on the mating surfaces, and when the grinding teeth are mated, there is generally a matching gap from large to small from bottom to top. The moving grinding head 41 can produce a certain rotational suction force when moving. When the motor 3 rotates at a high speed, the rotary suction force formed by the movable grinding head 4...

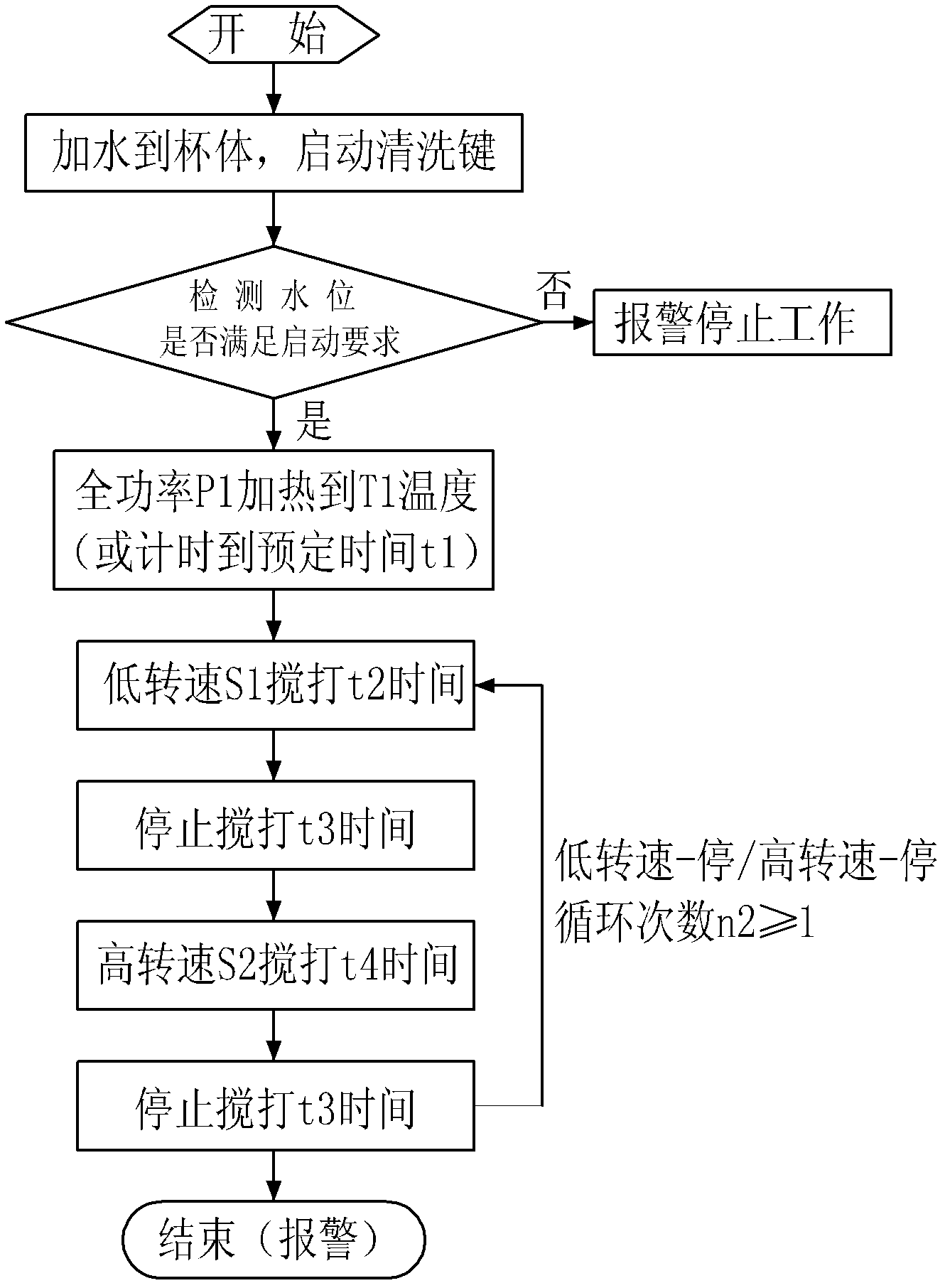

Embodiment 2

[0055] See attached figure 2 , attached Figure 6-8 , in order to protect the motor 3, after the low speed S1 whipping time t2 is completed, it is necessary to stop the whipping time t3, and then switch to the high speed S2 whipping time t4, the process in the cleaning stage is as follows: low speed S1 whipping Beating time t2→stop whipping time t3→high speed S2 whipping time t3→stop whipping time t3. It is a cycle of low rotation speed S1 and high rotation speed S2, and the number of cycles n2 is specifically 1 time. After that, the whipping will stop, an alarm will be given to remind the user, and the entire cleaning process will be completed. Other steps are the same as in Embodiment 1.

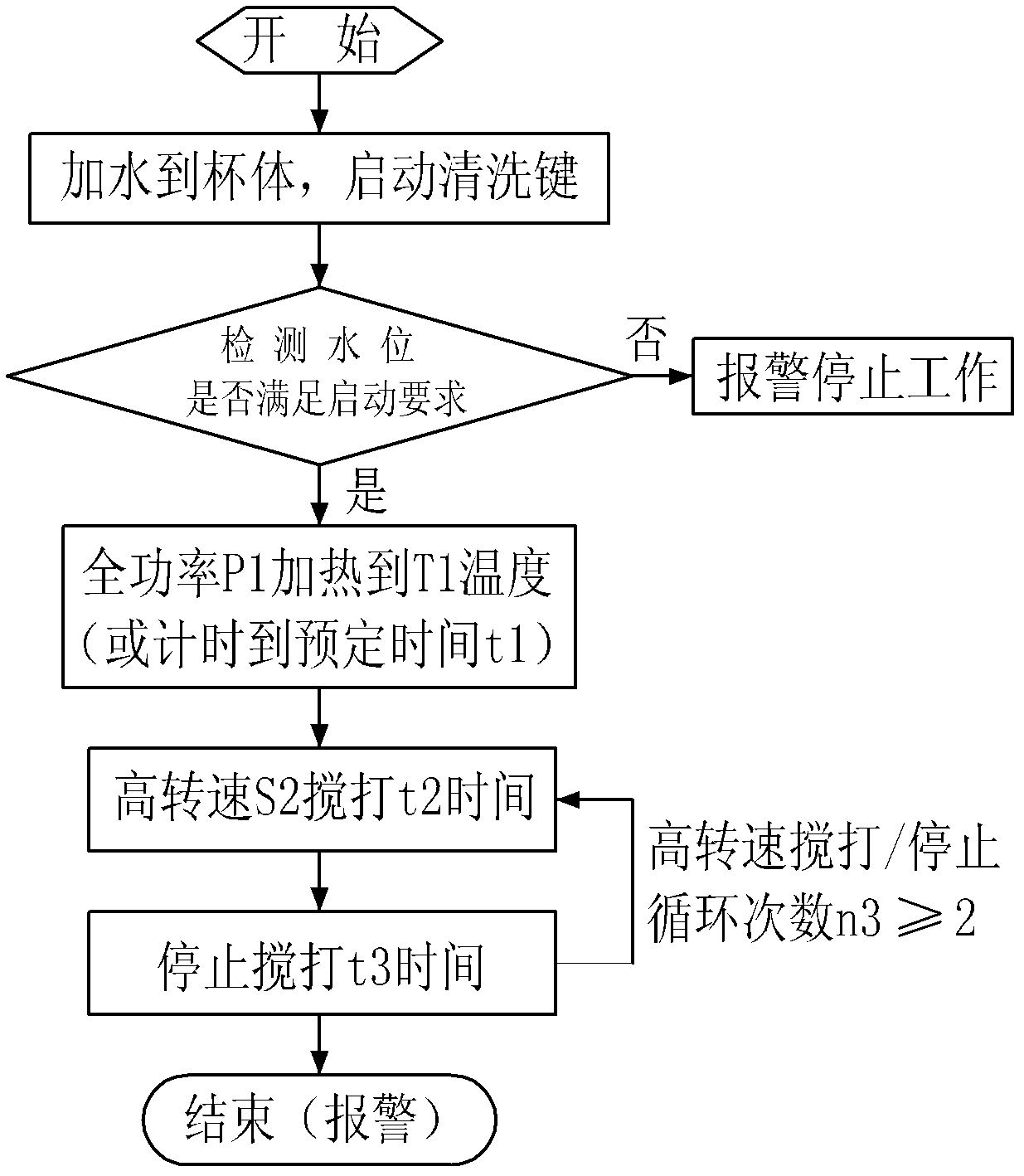

Embodiment 3

[0057] See attached image 3 , attached Figure 6-8 , in the cleaning stage, the motor speed is a single speed, that is, the motor 3 drives the grinding unit 4 at a single constant speed, combined with different grinding structures in the grinding soybean milk machine to whip and clean at a high speed, for example, set on the grinding unit 4 A diversion device, high-speed water flow through the diversion device to perform high-intensity scouring and cleaning of the grinding unit 4 and the slurry container 2, and the high-speed S2 whipping time t2 stops whipping, and the number of cycles n3 is specifically 2 times, Until the whipping is stopped, the cleaning is completed and an alarm is given to the user to complete the entire cleaning process. Other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com