A special grinding wheel for photovoltaic glass and its processing method

A photovoltaic glass and grinding wheel technology, which is applied in metal processing equipment, abrasive materials, grinding devices, etc., can solve the problems of weak adhesion between the diamond layer and the grinding wheel substrate, easy debris, poor cutting ability, etc., to achieve tight combination and avoid Good effect of disintegration and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

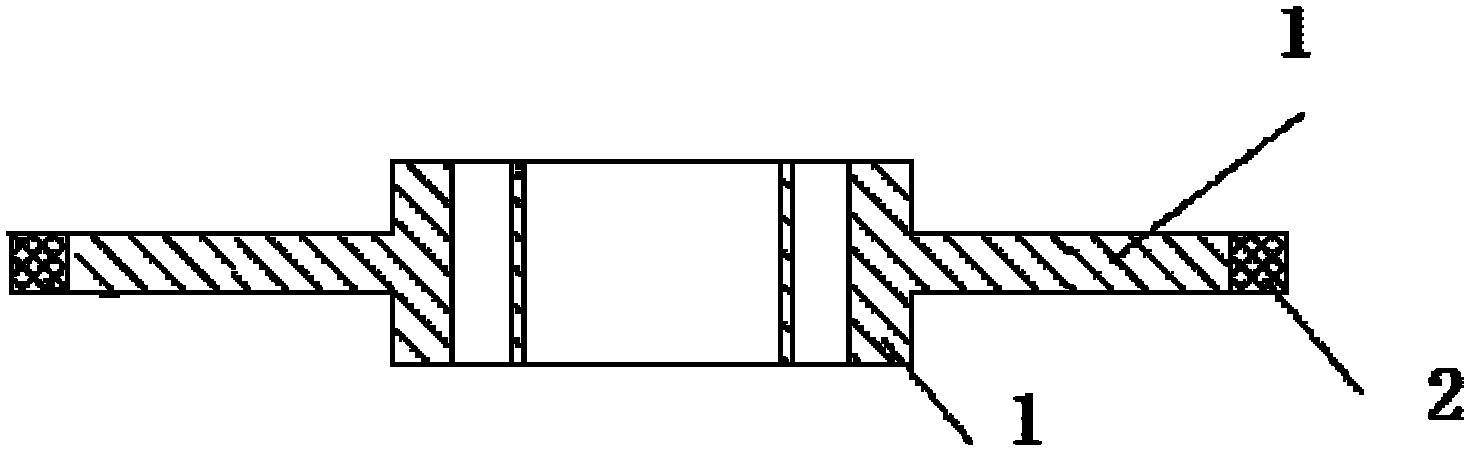

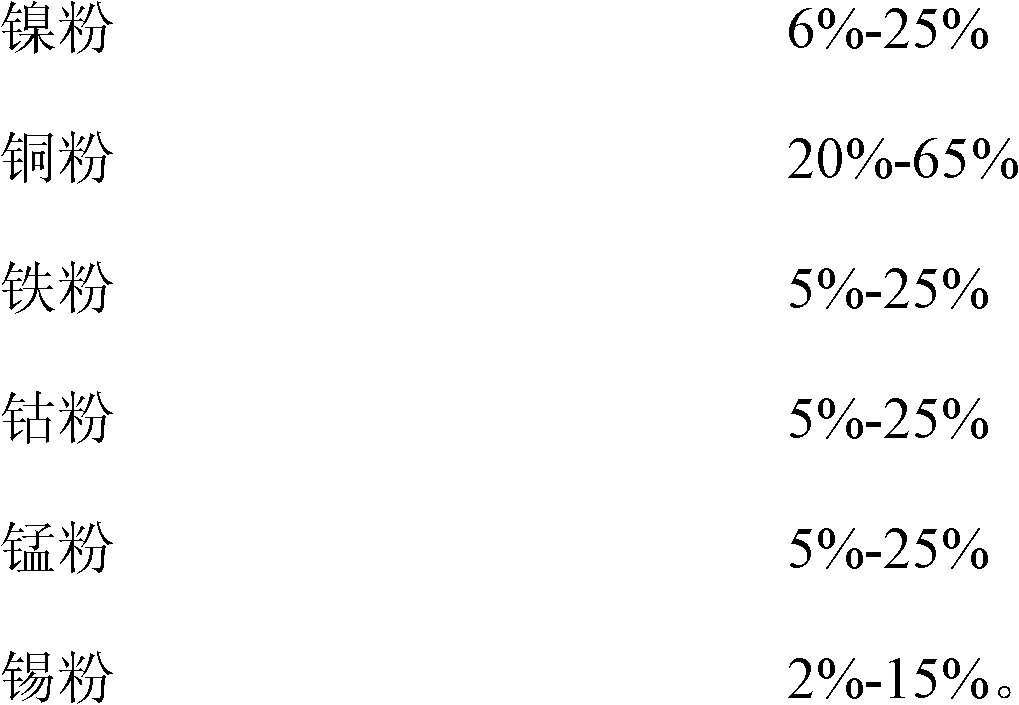

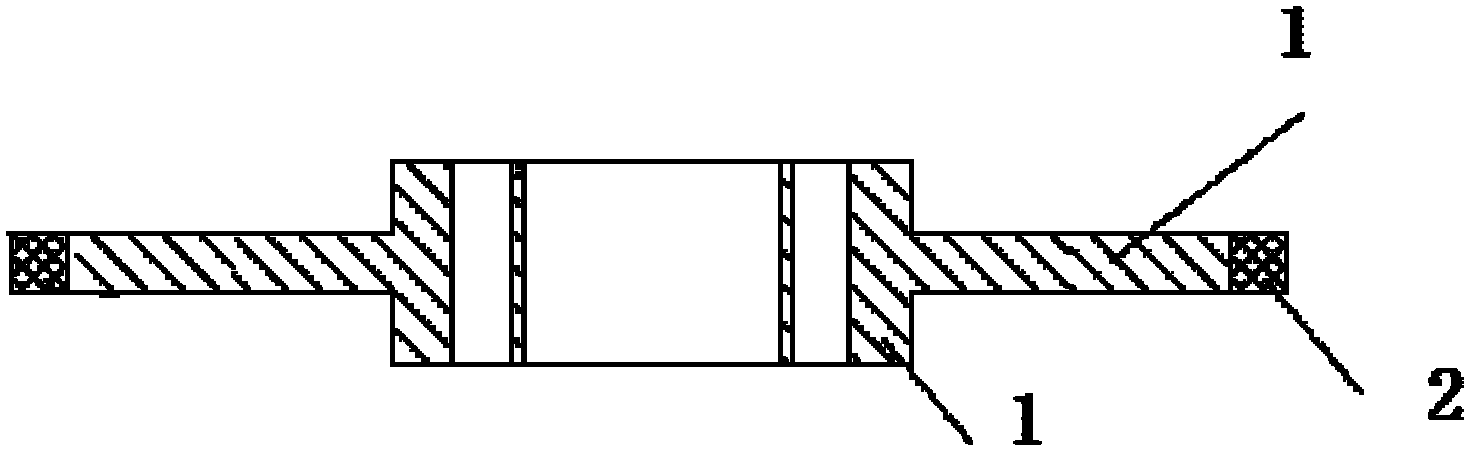

[0019] A special grinding wheel for photovoltaic glass, comprising a grinding wheel base 1, the edge of the grinding wheel base 1 is provided with a grinding layer 2, the grinding layer 2 is composed of diamond abrasives and a mixture, and the ratio of the diamond abrasive to the mixture is 1: 10 (weight ratio); the mixture is made up of 6% nickel powder, 65% copper powder, 5% iron powder, 5% cobalt powder, 5% manganese powder, and 14% tin powder. During processing, the A3 steel plate is first used to process the grinding wheel matrix; Prepare compound, calculate by weight percentage: the composition of nickel powder 6%, copper powder 65%, iron powder 5%, cobalt powder 5%, manganese powder 5%, tin powder 14% is weighed out with balance, stirs and mixes, Stir at a speed of 35r / min, stir for 30 minutes, and stir the mixture; then mix and stir the mixture with the diamond abrasive, the stirring speed is 25r / min, the mixture: diamond abrasive=10:1 (weight ratio) Cover the edge of ...

Embodiment 2

[0022] A special grinding wheel for photovoltaic glass, comprising a grinding wheel base 1, the edge of the grinding wheel base 1 is provided with a grinding layer 2, the grinding layer 2 is composed of diamond abrasives and a mixture, and the ratio of the diamond abrasive to the mixture is 1: 10 (weight ratio); the mixture is made up of 12% nickel powder, 30% copper powder, 18% iron powder, 20% cobalt powder, 10% manganese powder, and 10% tin powder. During processing, the A3 steel plate is first used to process the grinding wheel substrate; Prepare compound, calculate by weight percentage: the composition of nickel powder 12%, copper powder 30%, iron powder 18%, cobalt powder 20%, manganese powder 10%, tin powder 10% is weighed out with balance, stirs and mixes, Stir at a speed of 40r / min, stir for 25 minutes, and stir the mixture; then mix and stir the mixture with the diamond abrasive, the stirring speed is 25r / min, the mixture: diamond abrasive=10:1 (weight ratio) Cover t...

Embodiment 3

[0025] A special grinding wheel for photovoltaic glass, comprising a grinding wheel base 1, the edge of the grinding wheel base 1 is provided with a grinding layer 2, the grinding layer 2 is composed of diamond abrasives and a mixture, and the ratio of the diamond abrasive to the mixture is 1: 10 (weight ratio); the mixture is composed of nickel powder 25%, copper powder 20%, iron powder 5%, cobalt powder 25%, manganese powder 15%, tin powder 10%, during processing, first adopt A3 steel plate to process the grinding wheel matrix; Prepare compound, calculate by weight percentage: the composition of nickel powder 25%, copper powder 20%, iron powder 5%, cobalt powder 25%, manganese powder 15%, tin powder 10% is weighed out with balance, stirs and mixes, Stir at a speed of 47r / min, stir for 30 minutes, and stir the mixture; then mix and stir the mixture with the diamond abrasive, the stirring speed is 25r / min, the mixture: diamond abrasive=10:1 (weight ratio) Cover the edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com