A process for removing phosphorus from industrial wastewater

A technology for industrial waste water and technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Significant phosphorus effect, low maintenance cost, and low wastewater treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The basic properties of wastewater are as follows: (phosphorus content 100~1000ppm, pH 4.2)

[0017] Specific steps are as follows:

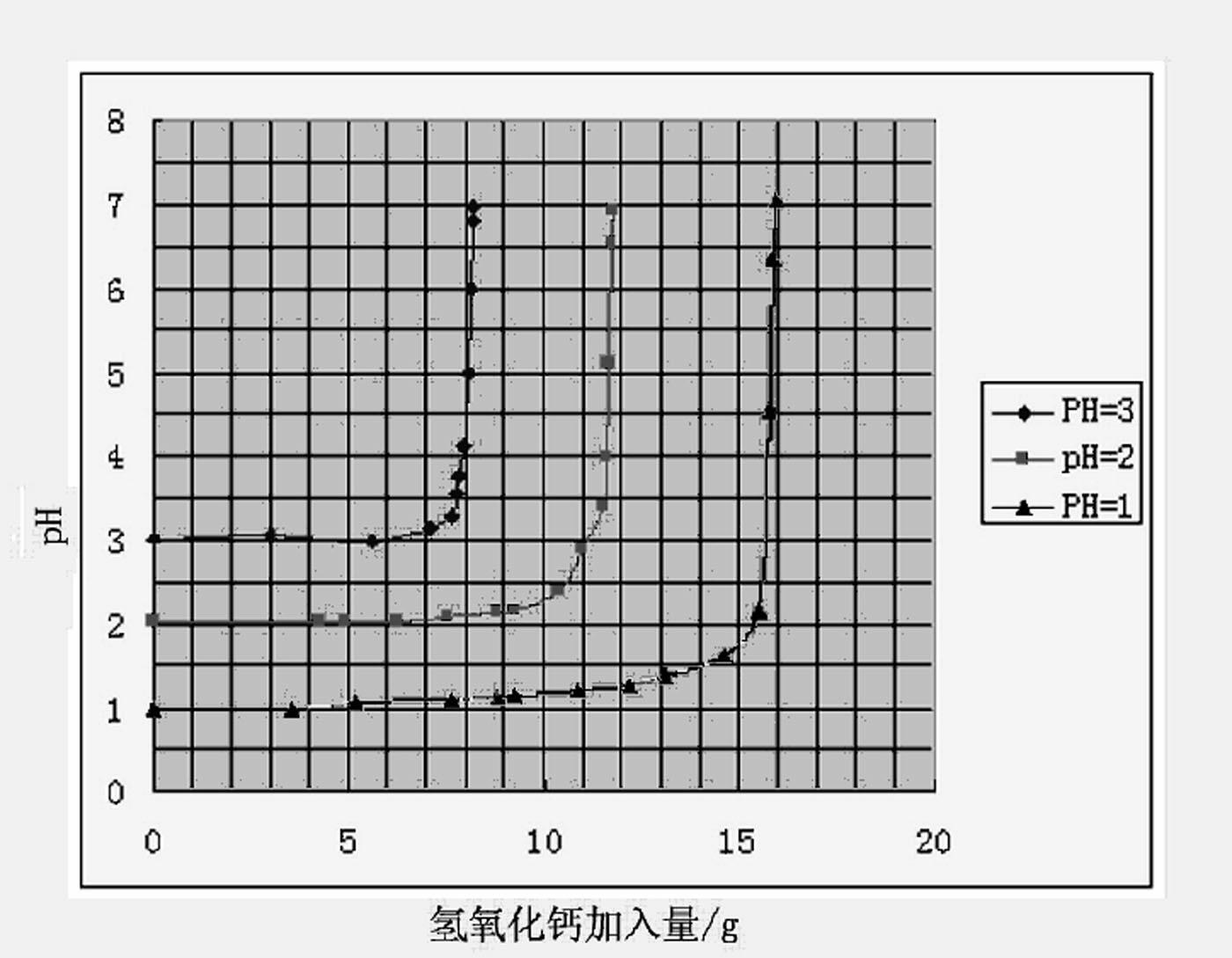

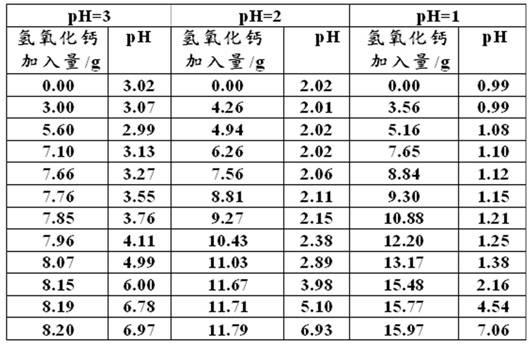

[0018] The first step: Take three parts of 0.5 liters of waste water, add sulfuric acid solution to adjust the pH value of the solution to 1.0, 2.0, and 3.0 respectively, stir well and add calcium hydroxide solid powder to it several times until the pH value of the solution is neutral. Table 1 has provided the change data of waste water pH along with calcium hydroxide solid powder addition; figure 1 The trend chart of wastewater pH with the addition of calcium hydroxide solid powder is given.

[0019] Table 1 The change data of wastewater pH with the addition of calcium hydroxide

[0020]

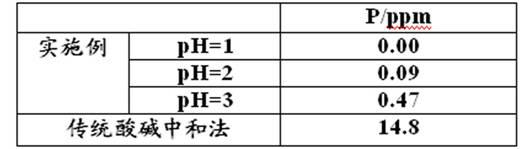

[0021] The second step: centrifugal separation, analysis of phosphorus content in the filtrate, the results are shown in Table 2.

[0022] Table 2

[0023]

[0024] It can be seen from the above chart that the change trend of ...

Embodiment 2

[0027] Before treatment, the basic properties of wastewater are as follows: (phosphorus content 100~1000ppm, pH 4.6)

[0028] Add sulfuric acid solution to 8 cubic meters of the above-mentioned wastewater to adjust the pH of the wastewater to 1, and then gradually add 30% to 40% calcium hydroxide slurry (the rest is water), totaling 200kg. After adding, the pH of the wastewater is 6.9-7.1. Precipitate was precipitated, centrifuged and filtered, and the phosphorus content in the filtrate was detected to be 0.027ppm. The phosphorus content in the filtrate treated by the traditional acid-base neutralization method is 38.37ppm.

Embodiment 3

[0030] Before treatment, the basic properties of wastewater are as follows: (Phosphorus content is about 2000ppm, pH 10.3)

[0031] Add sulfuric acid solution to 8 cubic meters of the above-mentioned wastewater to adjust the pH of the wastewater to 1, then gradually add 30% to 40% calcium hydroxide slurry (the rest is water), totaling 260kg, after adding, the pH of the wastewater is 6.9-7.1. Precipitate was precipitated, centrifuged and filtered, and the phosphorus content in the filtrate was detected to be 0.036ppm. The phosphorus content in the filtrate treated by the traditional acid-base neutralization method is 66.95ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com