A kind of preparation method of 2-(4-chlorophenethyl)-2-tert-butyl oxirane

A technology of tert-butyl oxirane and chlorophenethyl is applied in the field of preparation of 2--2-tert-butyl oxirane, can solve the problems of long production cycle, high boiling point of toluene, difficult precipitation and the like, and achieves the production cycle Shortening, low boiling point, low solvent consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

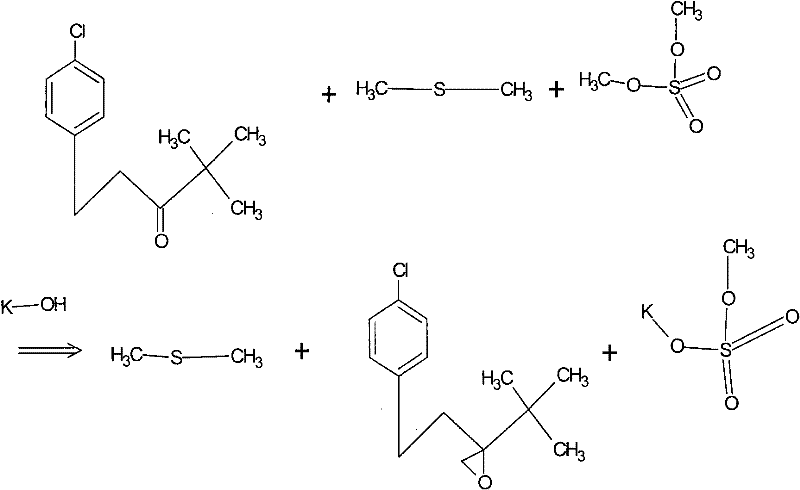

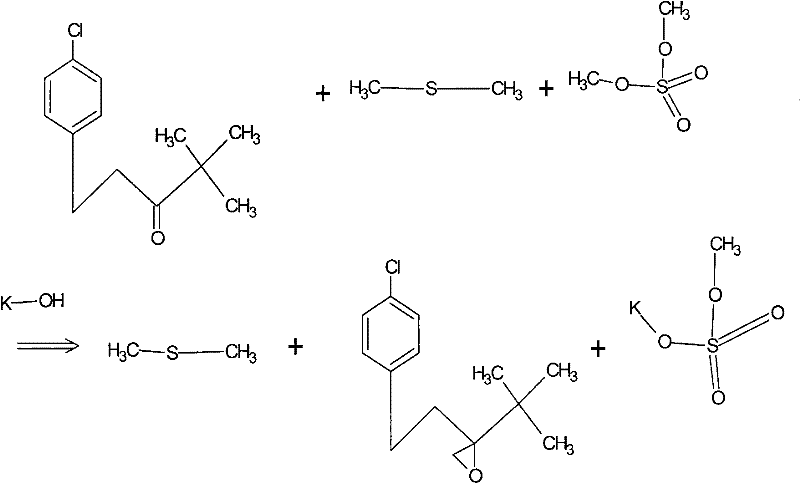

[0012] The preparation method of 2-(4-chlorophenethyl)-2-tert-butyl oxirane of the present invention, concrete technique is as follows: by 4,4-dimethyl-1-(4-chlorophenyl)-3- Pentanone, dimethyl sulfide, and dimethyl sulfate are produced by methylation reaction under potassium carbonate alkaline conditions. The specific steps are: first, dimethyl sulfide and dimethyl sulfate are at 20-30°C Synthesize the salt, and then react the generated salt with 4,4-dimethyl-1-(4-chlorophenyl)-3-pentanone at 30-40°C to generate 2-(4-chlorophenethyl)- 2-tert-butyloxirane, and at the same time, dimethyl sulfide is released. Its reaction formula is as shown in the accompanying drawing.

[0013] The molar ratio of raw materials in a chemical reaction:

[0014] 4,4-Dimethyl-1-(4-chlorophenyl)-3-pentanone: dimethyl sulfide: dimethyl sulfate: KOH = 1: 1.2-2.0: 1.1-1.8: 1.2-2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com