Preparation technology and anti-tumor application of modified pectin with high bioavailability

A technique of modifying pectin and utilization, which is applied in the direction of antineoplastic drugs, medical preparations containing active ingredients, drug combinations, etc. It can solve the problems affecting the efficacy of MPHB, achieve control of molecular weight and distribution, and improve biological The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

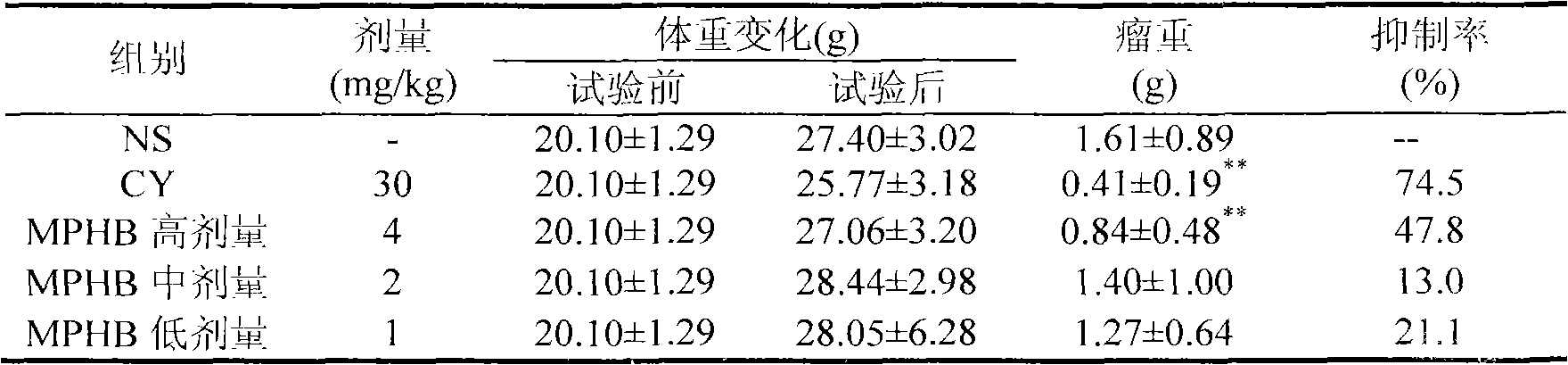

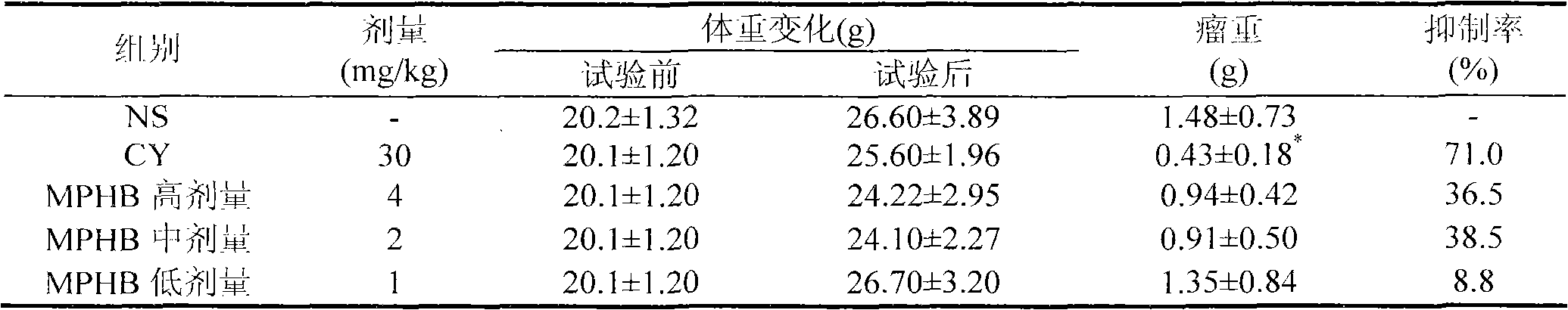

Examples

Embodiment 1

[0026] Weigh 5kg of citrus pectin with an esterification degree of 60%, add 5000L of water, mix, heat to 60°C, and keep for 12h to fully swell; cool to 45°C, and adjust the pH to 8.0 with sodium carbonate solution in the same container, Add commercially available pectin esterase and stir evenly. It was determined that when the degree of pectin esterification was reduced to 1%, the temperature was raised to 80° C. and kept for 1 hour to terminate the action of pectin esterase. Commercially available polygalacturonase was added to the same container, and after enzymatic degradation, the molecular weight and molecular weight distribution were detected by high performance gel chromatography, so that the peak average molecular weight of the main components of the product was in the range of 70000Da to 2000Da. Use the first set of membranes with a molecular weight cut-off (hereinafter referred to as MWCO) of 100,000Da to separate and remove high-molecular-weight pectin and enzymes; ...

Embodiment 2

[0028] Weigh 100kg of ponkan peel pectin with a degree of esterification of 40%, add 1000L of water, mix, heat to 95°C, keep for 3h, and swell; cool to 55°C, and adjust the pH to 4.5 with potassium carbonate solution in the same container , add pectin esterase and stir evenly. It was determined that when the degree of pectin esterification decreased to 0.4%, the temperature was raised to 90°C and kept for 30 minutes. Pectin lyase is added into the same container, and through enzymatic degradation, the peak average molecular weight of the main components of the product is in the range of 50000Da to 2000Da. A membrane with a MWCO of 70,000Da was used to separate and remove high-molecular-weight pectin and enzymes; a membrane with a MWCO of 45,000Da was used to concentrate the pectin solution, and the product was spray-dried to obtain 83.50kg of MPHB with antitumor activity and oral administration.

Embodiment 3

[0030] Weigh 1kg of pomelo (Citrus grandis) peel pectin with a degree of esterification of 70%, add 50L of water, mix, heat to 90°C, keep for 8h, and swell; cool to 50°C, and adjust the pH to 8.5, add pectin esterase and stir evenly. It was determined that when the degree of esterification of pectin decreased to 10%, the temperature was raised to 85°C and kept for 90 minutes. A mixture of pectin lyase and polygalacturonase is added to the same container, and the peak average molecular weight of the main components of the product is about 20,000 Da through enzymatic degradation. MWCO 80000Da membrane was used to separate and remove high molecular weight pectin and enzymes; MWCO 20000Da membrane was used to concentrate the pectin solution, and the product was freeze-dried to obtain 0.68kg MPHB with anti-tumor activity and oral administration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com