igh temperature PWHT softening and production method thereof

A steel plate and fire-shaped technology, which is applied in the field of normalized steel plates for pressure vessel shells, can solve the problems of structural degradation, increased processing and production costs, and unsuitable high-temperature resistant PWHT low-alloy vessel steel plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

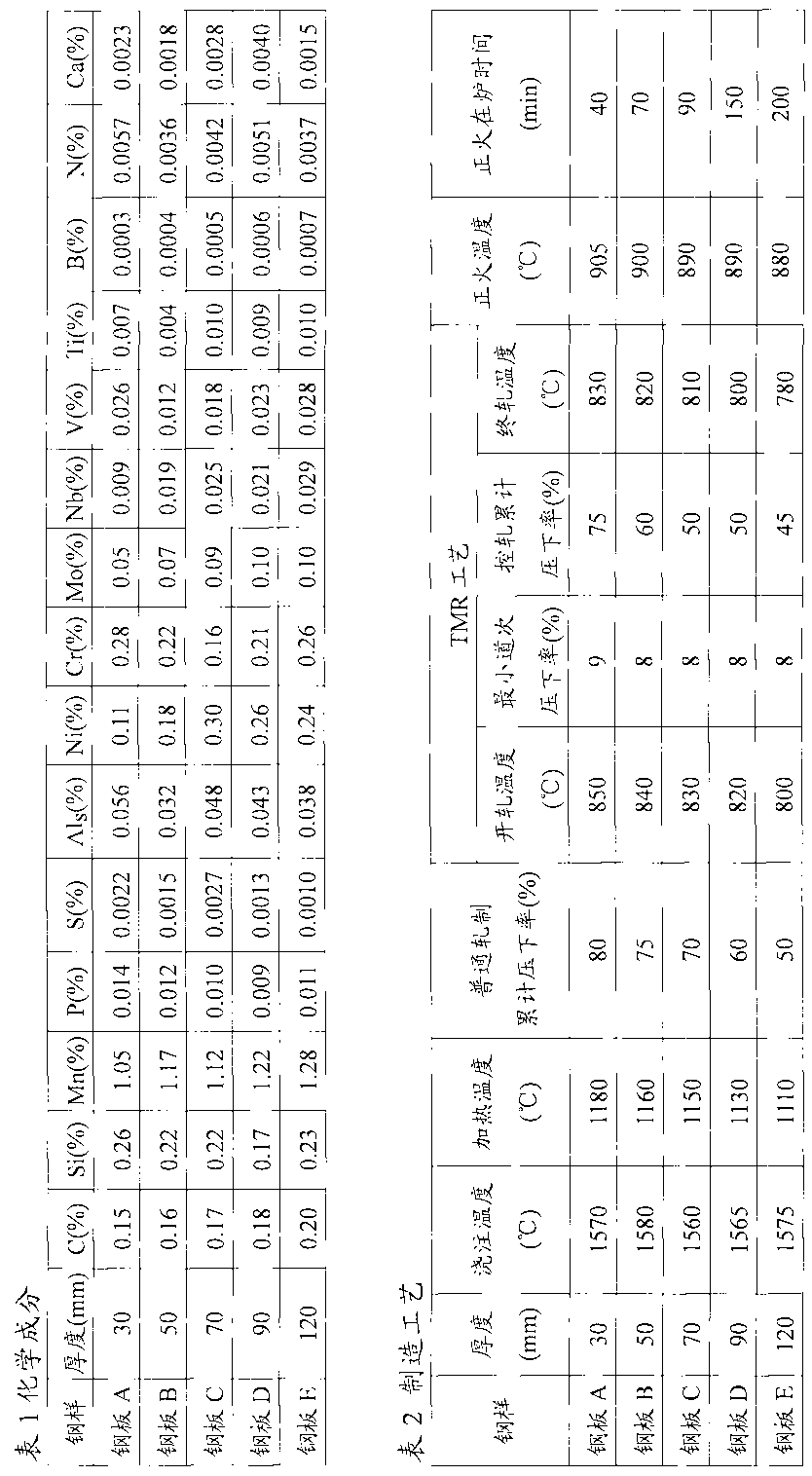

[0063] The chemical composition of embodiment is shown in Table 1, manufactures according to the following steps:

[0064] TDS molten iron deep desulfurization→converter smelting→LF→RH (Si-Ca wire feeding)→die casting→slab off-line finishing→slab cutting to length→heating→thermomechanical rolling (TMR)→steel stack slow cooling / Pit slow cooling→AUT / MUT→Steel edge trimming, head and tail cutting→Rough shot blasting to remove scale on the steel plate surface→Normalizing heat treatment (N)→Sampling and performance testing (including sample simulation PWHT)→Cut to length steel plate →Surface quality and appearance size, identification and inspection →Factory.

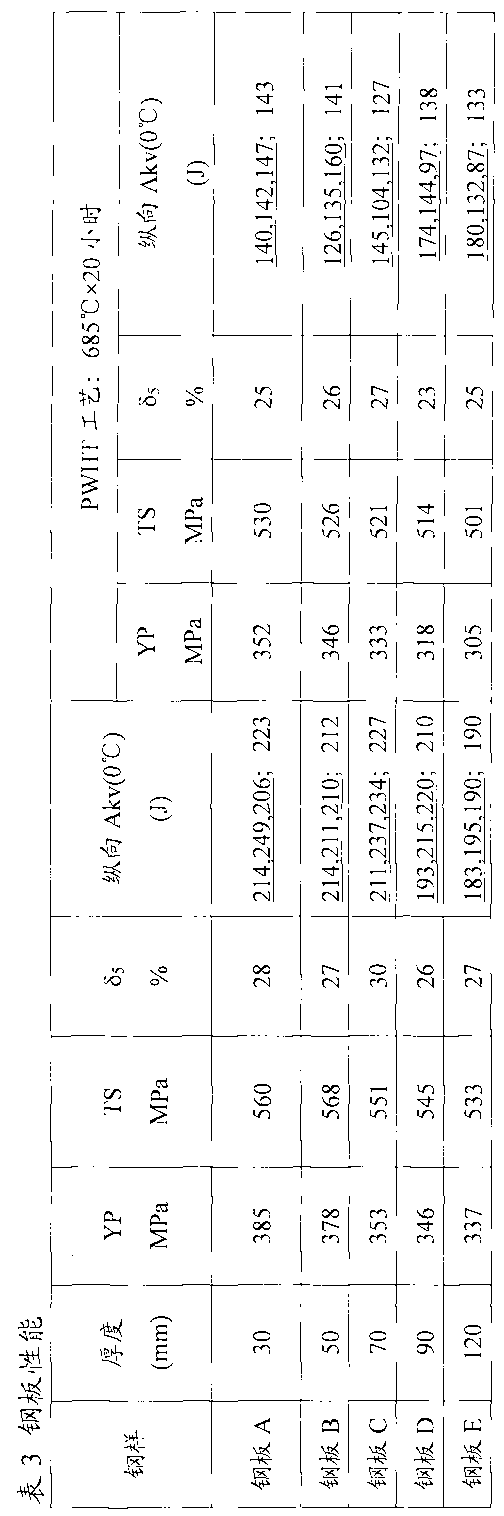

[0065] The technological parameters of the embodiment are shown in Table 2, and the performance parameters are shown in Table 3.

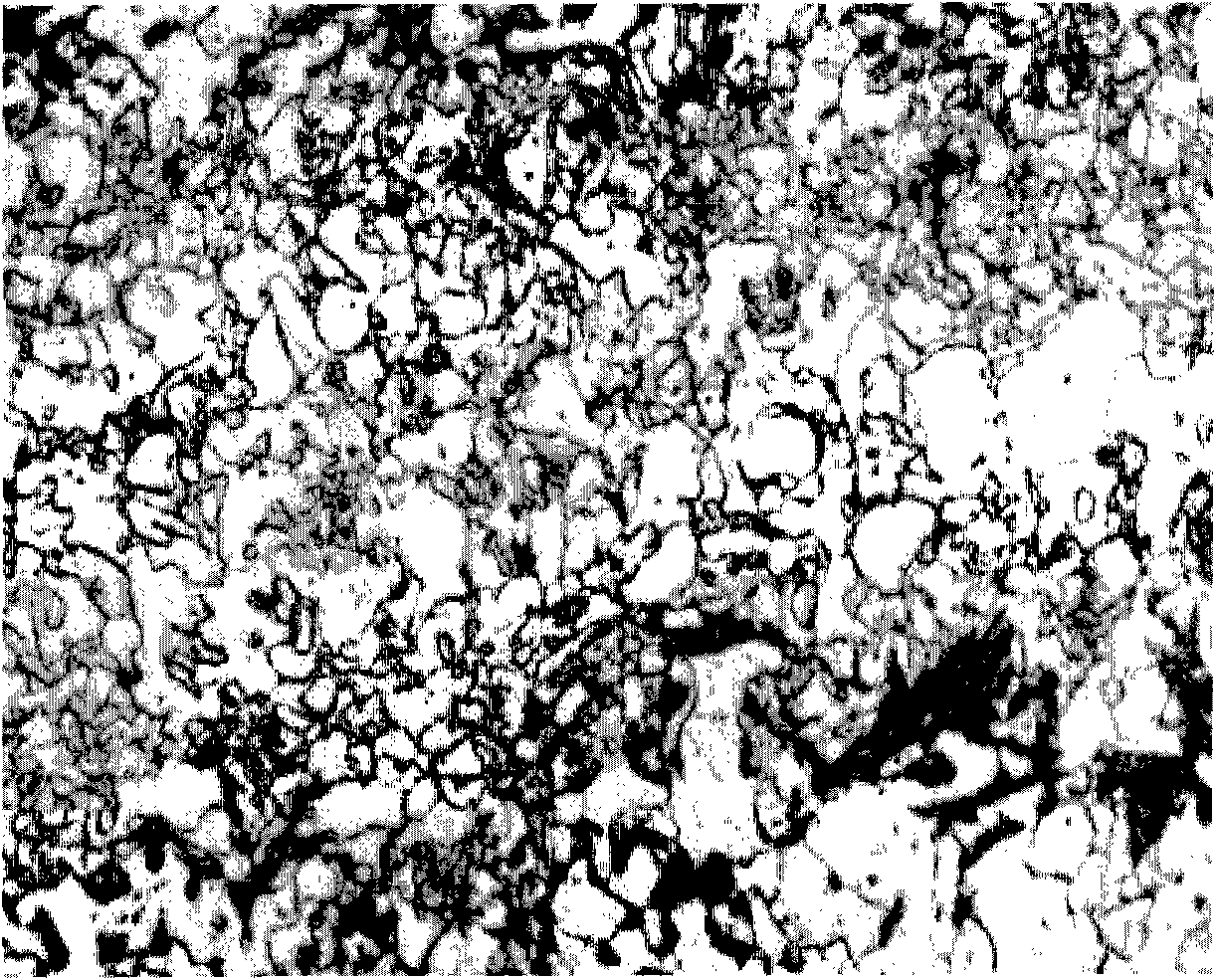

[0066] see figure 1 It can be seen that the structure of the steel plate of the present invention is uniform and fine equiaxed ferrite grains + metamorphic pearlite + granular bainite + a smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com