A Stress Joint Based on Top Tensioning Riser and Its Optimal Design Method

A stress joint and top tensioning technology, applied in casing, drill pipe, calculation, etc., can solve the problem that the stress joint is difficult to meet the functional and economical requirements, and achieve a simple and easy design process and reduce bending Stress, Effect of Low Elastic Modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

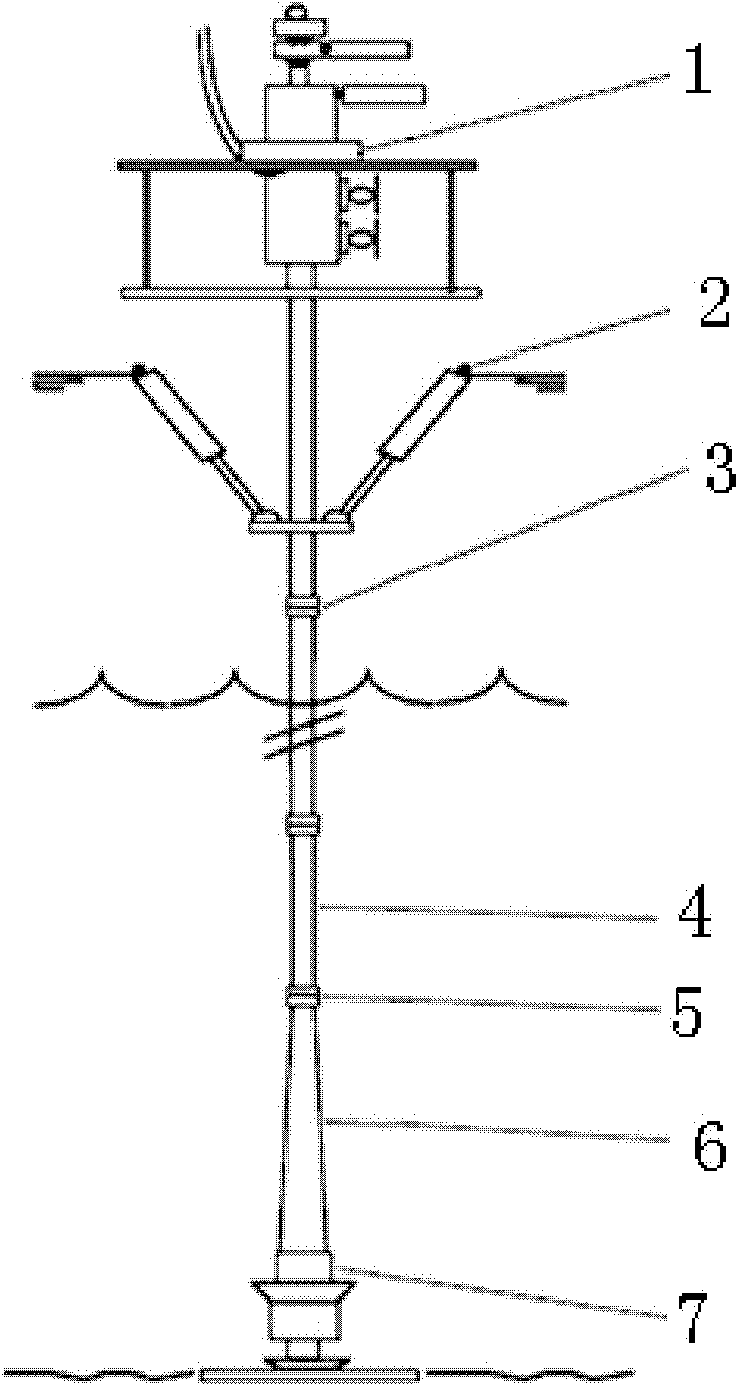

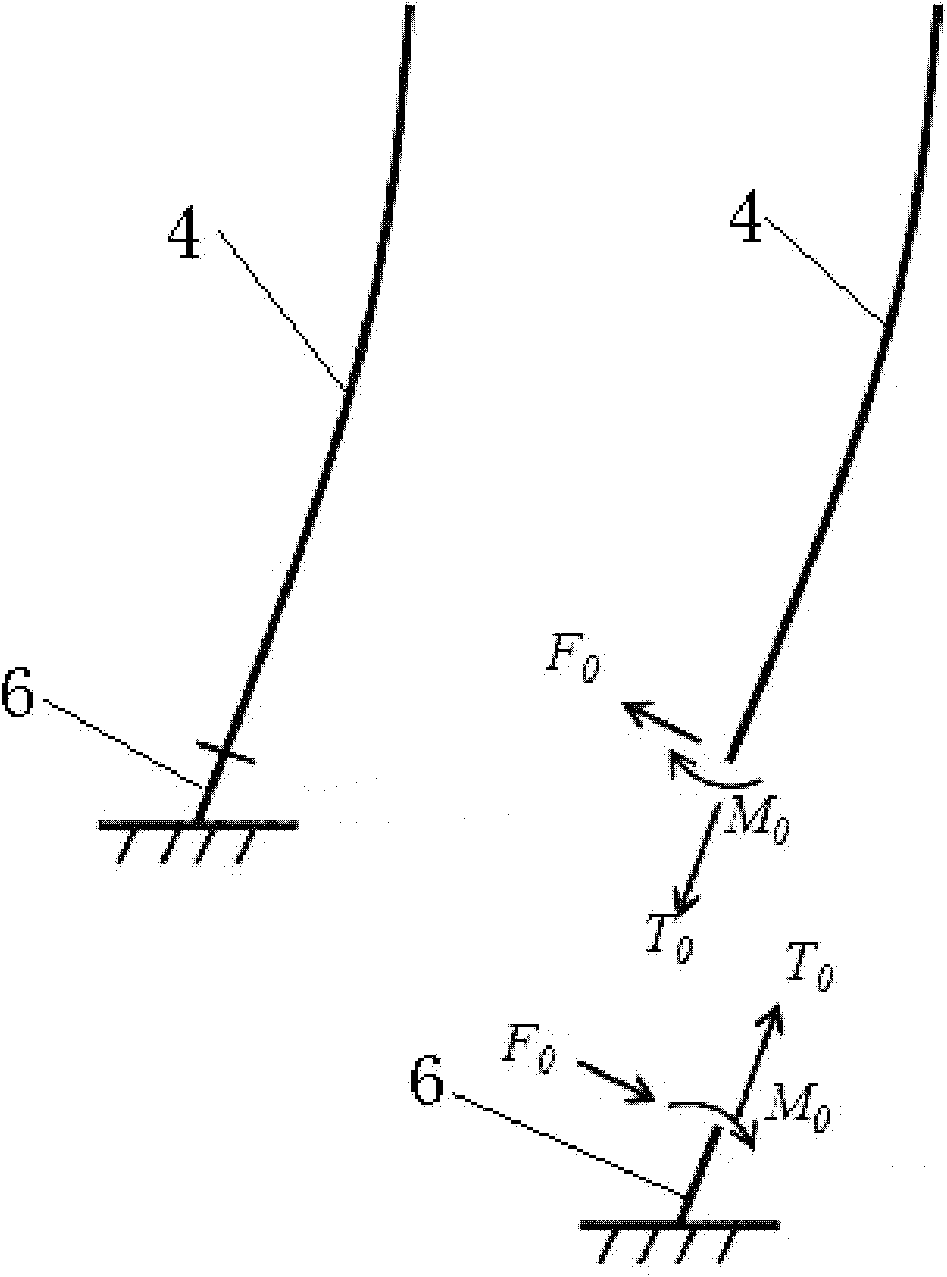

[0037] Such as figure 1As shown, the top tensioned riser system includes a surface Christmas tree 1 , a tensioner 2 , a tensioner joint 3 , a riser 4 and a riser joint 5 . The stress joint 6 of the present invention is arranged at the bottom of the entire top tension riser system, its top end is connected with the riser joint 5 , and its bottom end is connected with the underwater well head system through a tie-back joint 7 .

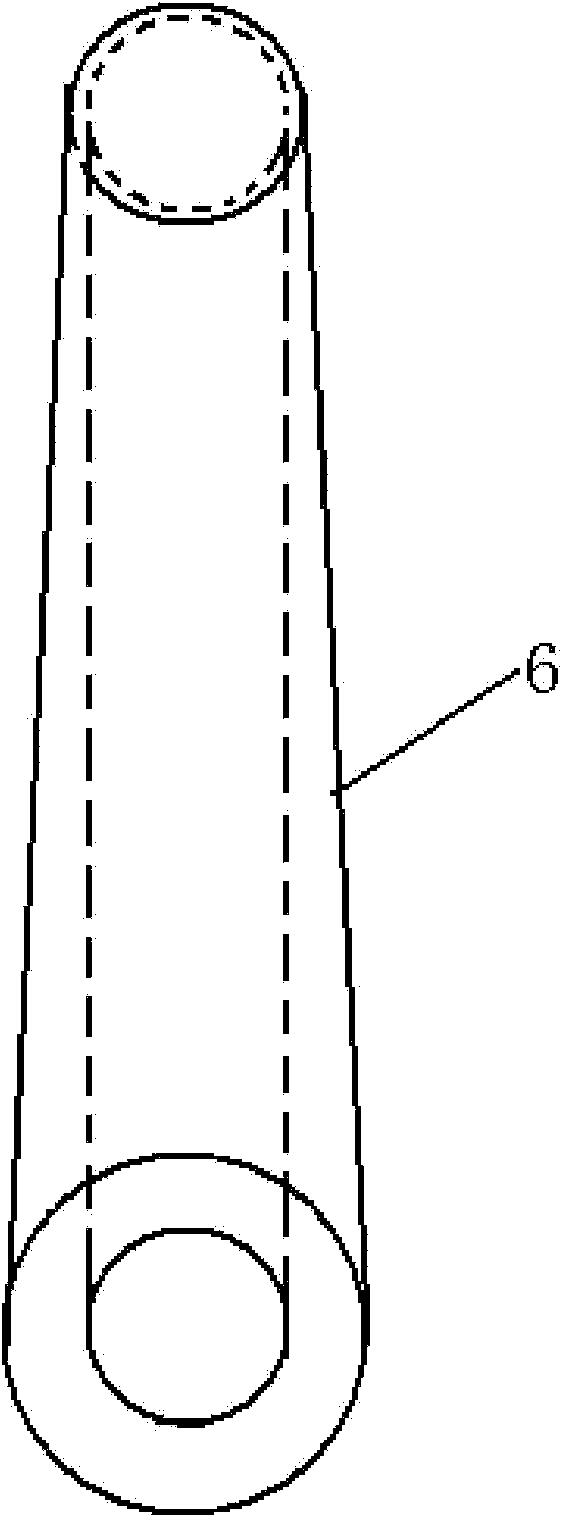

[0038] Such as figure 2 As shown, the stress joint 6 of the present invention is in the shape of a cone, its inner diameter is constant, its outer diameter gradually increases from the top to the bottom, and its wall thickness gradually increases.

[0039] The stress joint 6 of the present invention is made of titanium-aluminum alloy with high strength and low elastic modulus, and can withstand high stress, high bending mome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com