A roadway support technology in high level stress unfavorable rock strata

A roadway support, high-level technology, applied in the direction of tunnels, tunnel linings, temporary shields, etc., can solve the problems of poor support effect and single roadway support mode, so as to ensure stability, good support effect and save energy. The effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

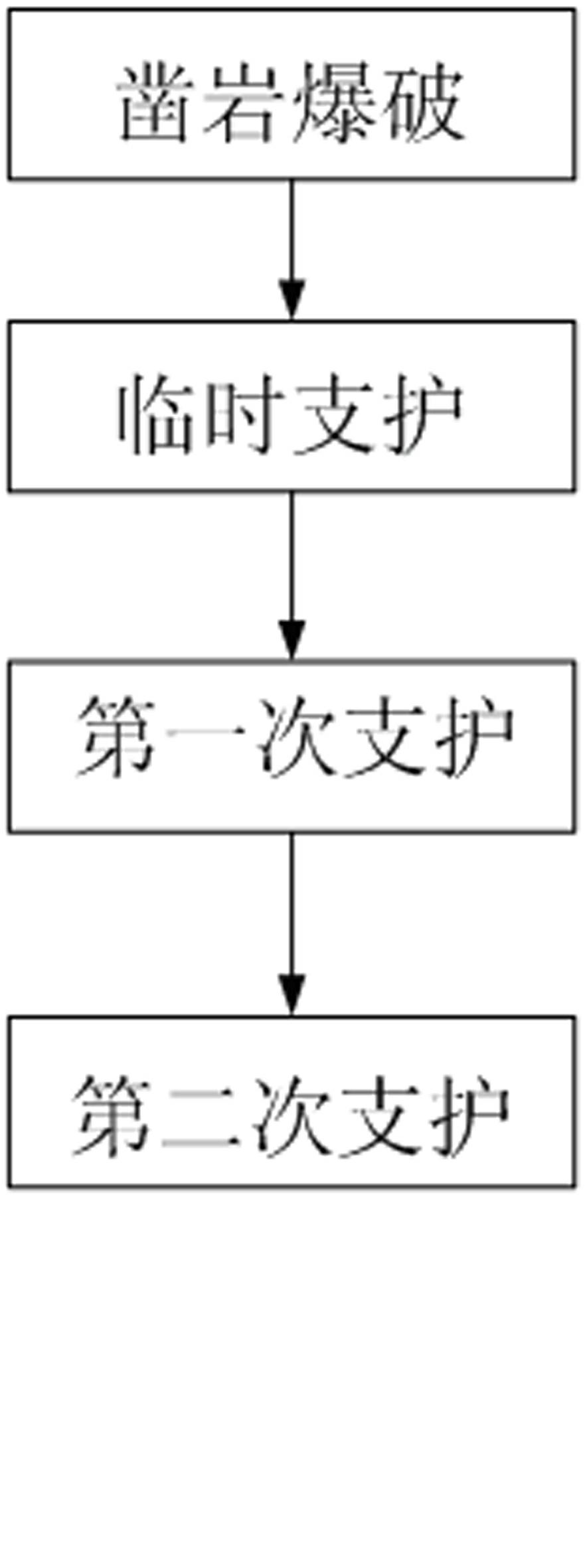

[0031] A roadway support technology for high-level stress unfavorable rock formations, such as figure 1 As shown, it includes the following steps:

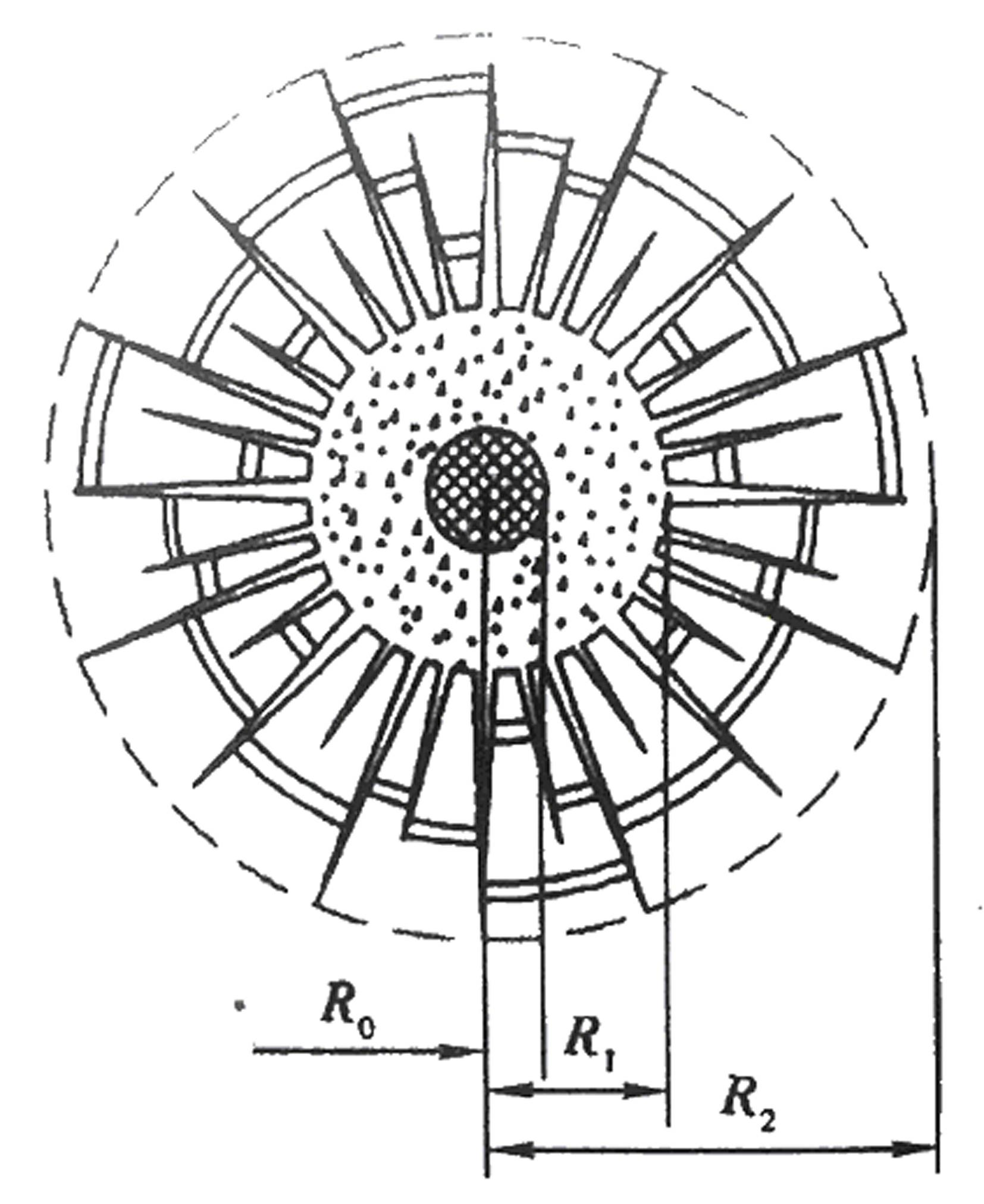

[0032] Step a, rock drilling and blasting to excavate the roadway, the process of rock drilling and blasting to excavate the roadway should meet the following process parameters: the distance between the surrounding holes is less than 2R 2 , the peripheral eye contour retraction data should be slightly larger than R 2 value, in the range R 2 1~1.1 times of the value, among them, R 2 Represents the radius of the broken loose circle of rock mass blasting, or, the method of charging through the eye is adopted, and the amount of charge in the peripheral eye shall not ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com