An inner liquid-distributing hood type condensing heat exchange tube

一种换热管、内分液的技术,应用在换热器外壳、间接换热器、管状元件等方向,能够解决传热恶化等问题,达到消除液桥、提高传热效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

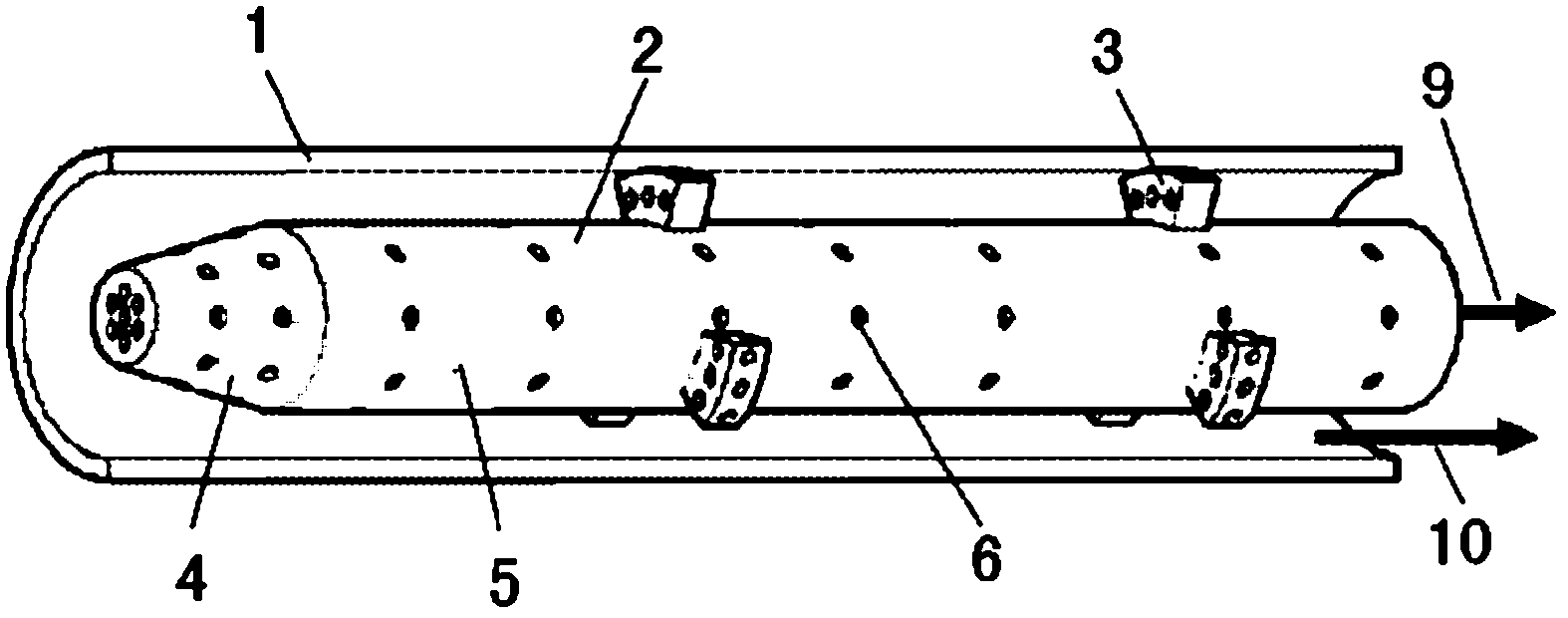

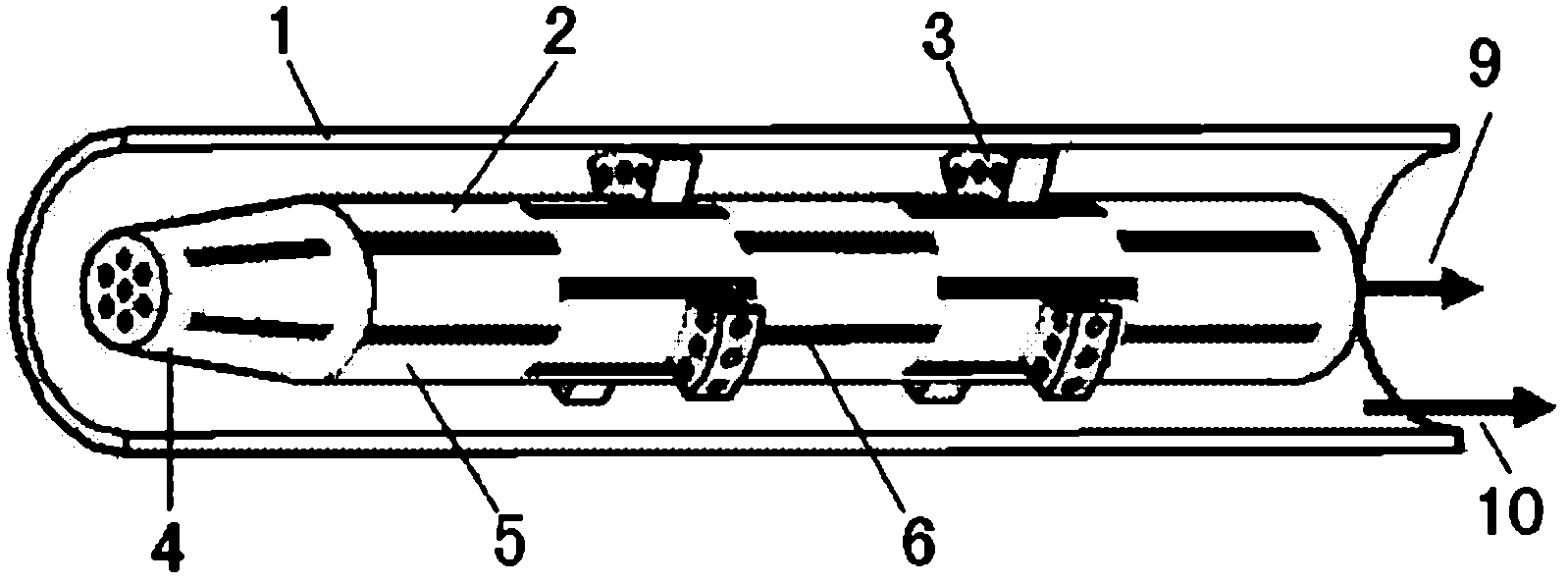

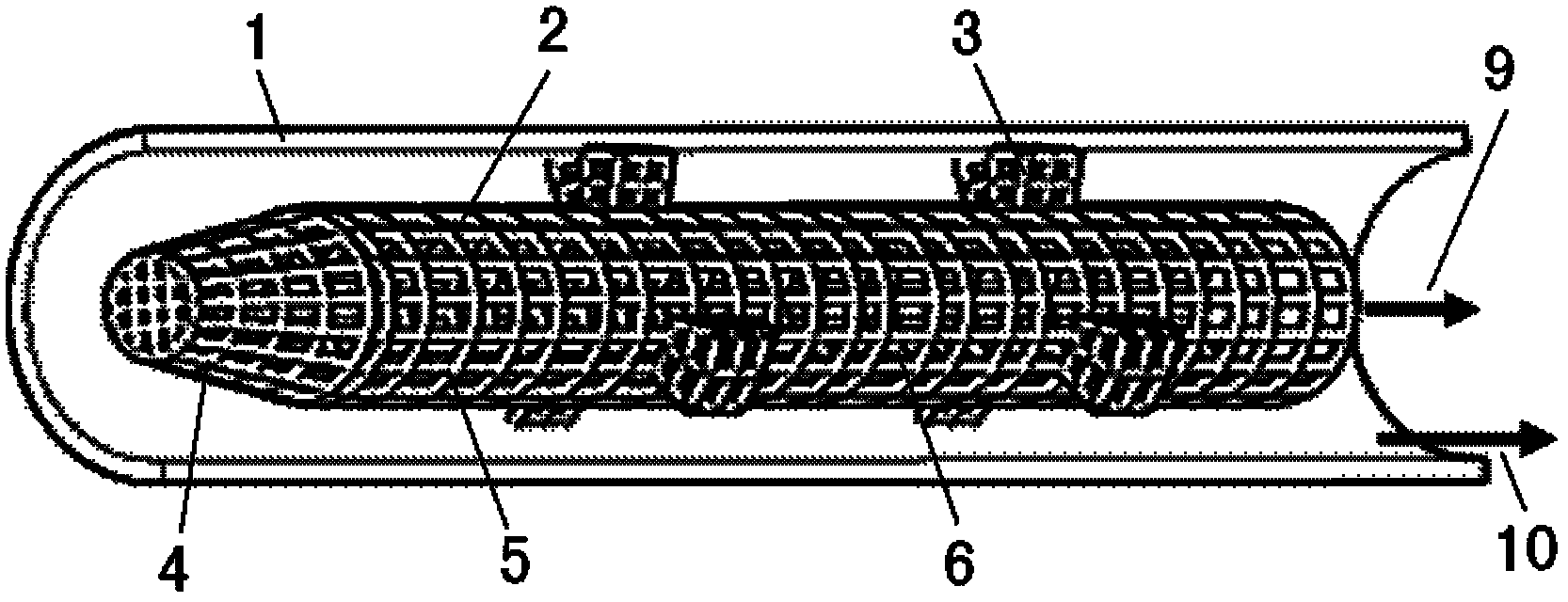

Embodiment 1

[0037] For the condensed water heat exchange process, a 50cm-long φ12mm×1mm ordinary smooth copper tube is selected as the outer heat exchange tube 1; a wire mesh with a mesh number of 14, a wire diameter of 0.4mm, and an aperture of 1.4mm is selected, and the length is 35cm, and the width is 1.4mm. Be the rectangular silk screen of 18.84mm (width is equal to 5 pipe circumferences of main distributing cover), roll into the cylindrical main dispensing cover 5 of inner liquid dispensing cover 2 of φ 6mm, long 35cm. Get the same screen, cut a trapezoidal roll to make the frustum-shaped drag-reducing cover 4 sides, and a circle as the drag-reducing cover 4 top cover. And cut a plurality of fan-shaped wire mesh to make a wire mesh structure support with a height of 2mm. Weld the drag reducing cover 4, the main liquid separating cover 5 and the wire mesh support 3 into one, and put them into the smooth outer heat exchange tube 1 to obtain an inner liquid separating cover type conden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com