Method for improving heating uniformity of electric heating film and electric heating film with uniform heating

An electric heating and uniformity technology, which is applied in the field of improving the heating uniformity of the electric heating film, can solve the problems of no substantial breakthrough or confidentiality, and achieve the goal of solving the problem of uneven heating, reducing the unevenness, and opening up room for development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

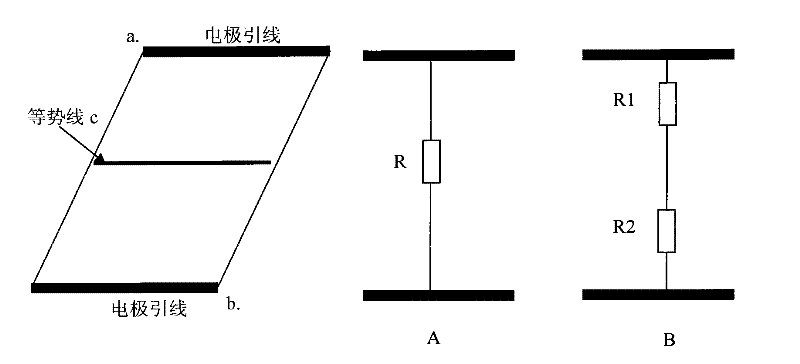

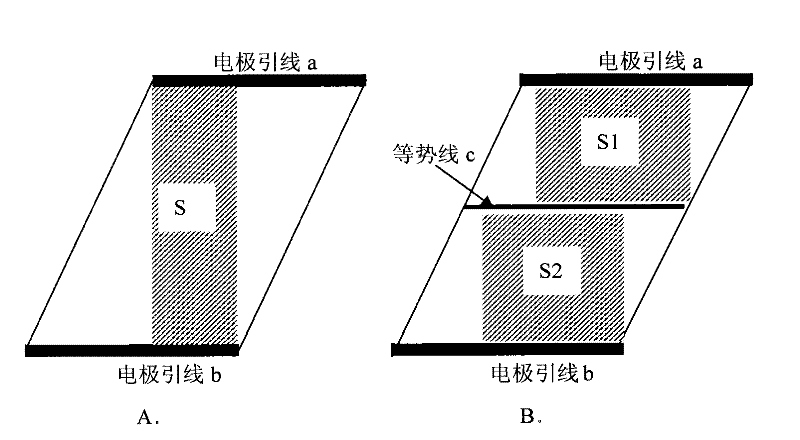

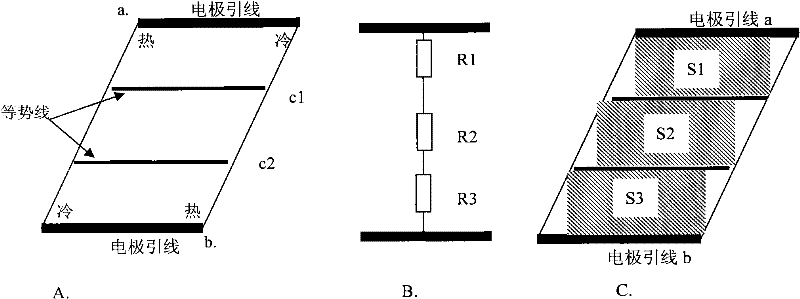

[0018] To solve the problem of non-uniform heating in the working area of the non-rectangular transparent conductive film, the present invention proposes a solution, that is, add a forced equipotential line between the positive and negative electrode leads of the film, and the forced equipotential line can be one or several metal wires.

[0019] As a conductive film with a heating function, its basic structure is to be equipped with electrode leads on a group of opposite sides of the film, and the electrode leads are connected to the positive and negative electrodes of the power supply to form a conductive circuit.

[0020] The present invention adds metal wires between positive and negative electrode lead wires. The metal wires are attached to the film by means of mechanical external force, bonding, etc., and the metal wires as equipotential lines should form good electrical contact with the film.

[0021] The principle of adding forced equipotential lines in the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com