Mechanized production method for convenient instant meat swallow shreds

A production method and technology of swallow silk, applied in food preparation, food science, application, etc., can solve the problems of unconventional flavor, difficult mechanized production of ready-to-eat meat swallow silk, and lack of nutrition in instant noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

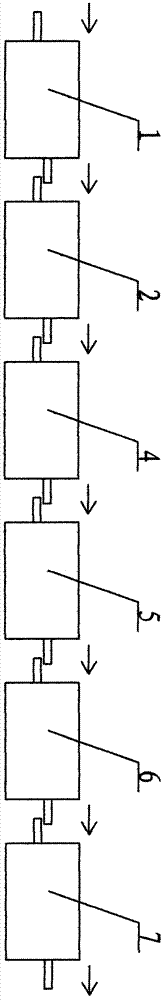

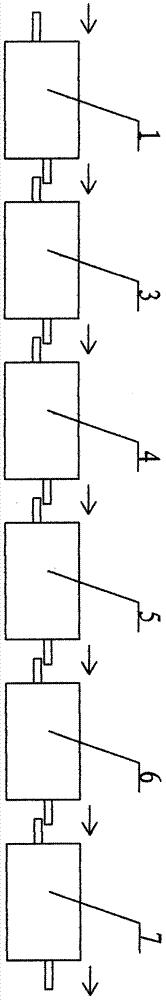

[0021] Embodiment: The meat paste dough synthesized by fresh lean meat traditional raw materials through beating process and adding traditional formula is input into noodle rolling machine 1, and the follow-up arrangement of noodle rolling machine 1 is relatively formed by steam chamber 2 or steam Stock pot room 3, air-drying room 4, filament forming machine 5, drying room 6, vacuum packaging machine 7, each equipment is equipped with a conveying device and forms a split-level connection link corresponding to the front and rear production processes, and the linked equipment Composition of machine-mapping assembly line for the production of instant deli meat and swallow silk.

[0022] The above-mentioned dough rolling machine 1 is a special mechanical equipment of the mechanized rolling and forming machine for the meat swallow skin to complete the rolling and rolling of the meat paste dough to form a continuous output of thin strips of meat swallow skin as thin as paper strips. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com