Tobacco rod weight control method and device based on microwave source

A technology of weight control and microwave source, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of long-term potential hazards of surrounding personnel, inconvenience of tobacco factories, expensive maintenance and maintenance costs, etc., and achieve good interactivity, maintenance and The effect of low maintenance cost and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

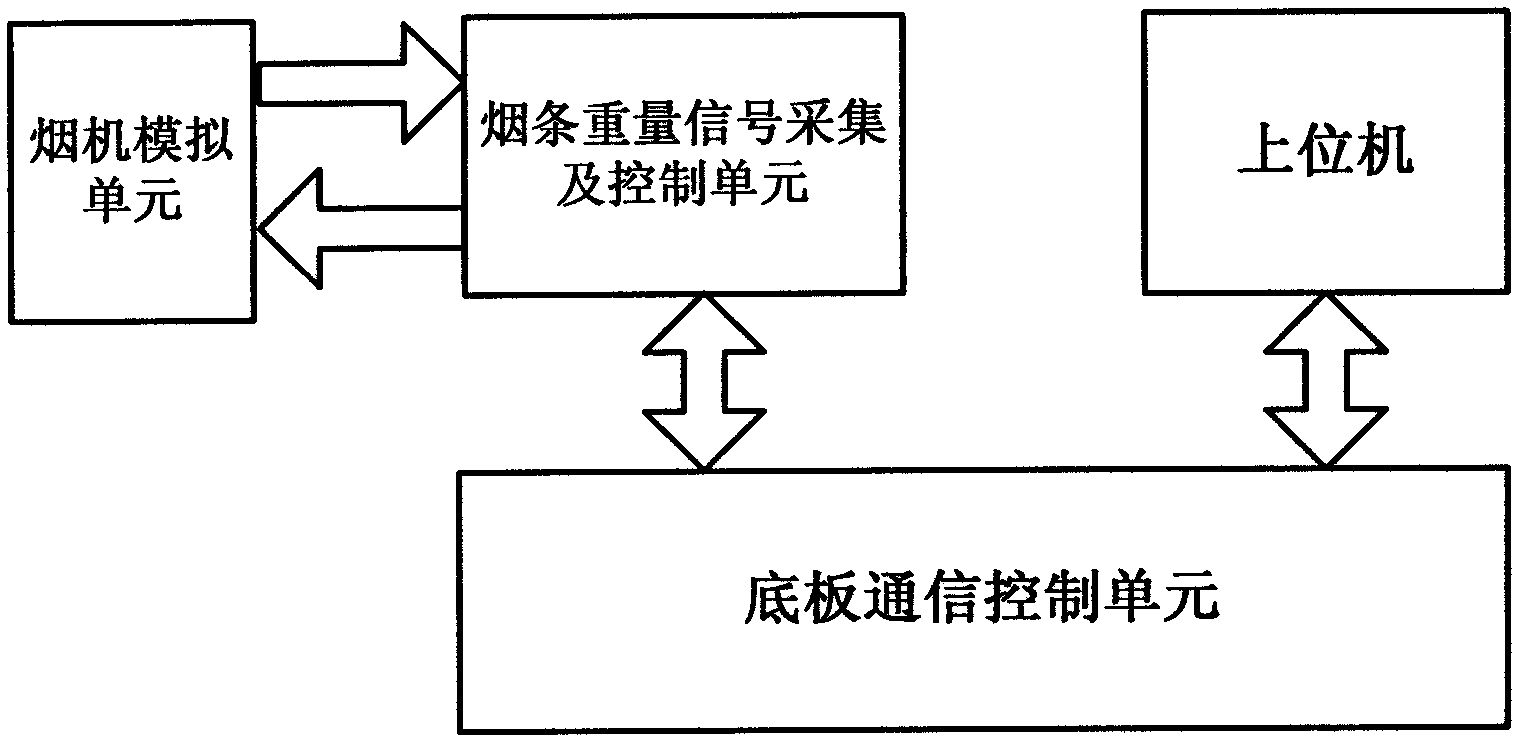

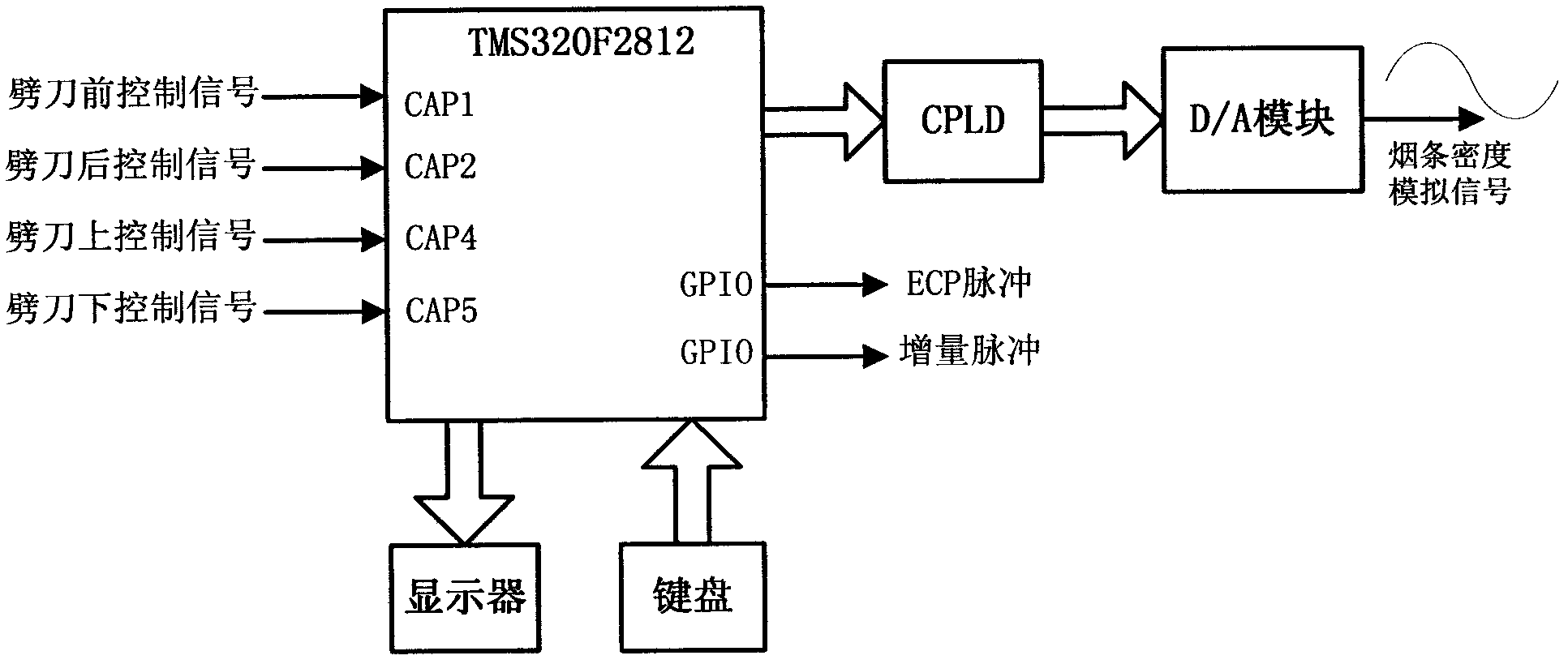

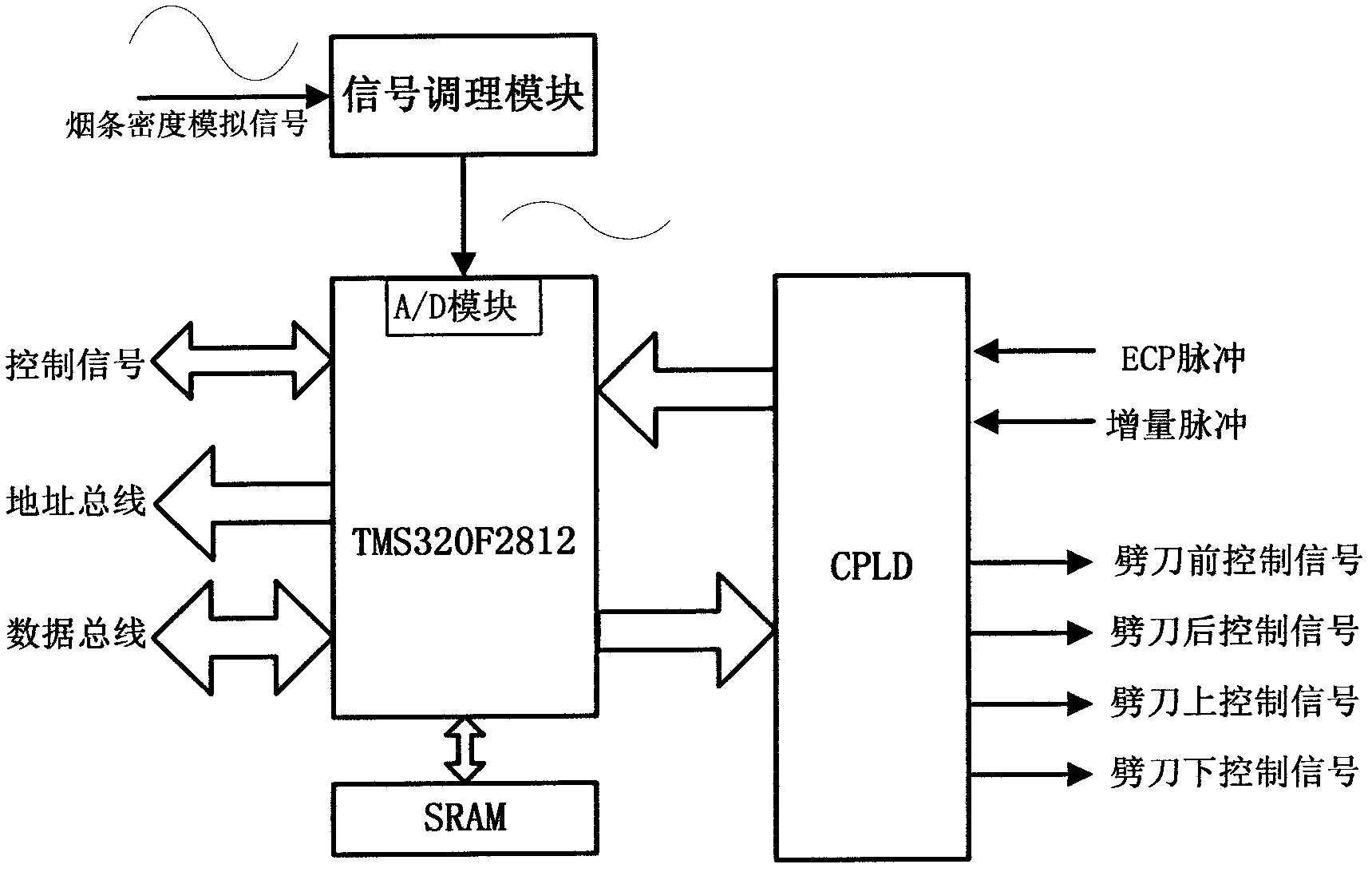

[0029] refer to figure 1 , The microwave source cigarette rod weight control device of the present invention includes a cigarette machine simulation unit, a cigarette rod weight signal acquisition and control unit, a bottom board communication control unit and a host computer unit. Among them, the smoke machine simulation unit imitates the working principle of the real smoke machine and the microwave source detector, generates the same sinusoidal analog voltage signal as the output of the microwave source detector - the analog signal of tobacco rod density, and sends the signal to the cigarette rod weight signal acquisition and control unit; tobacco rod weight signal acquisition and control unit first performs signal conditioning on the input analog signal of tobacco rod density, then performs A / D sampling to obtain digital signal of tobacco rod density, and then performs weight control and tight end tracking on the digital signal Processing, generating the chopper motor contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com