A helical end mill

An end mill and spiral technology, applied in the field of spiral end mills, can solve the problems of reduced surface processing quality of parts, low machining efficiency, scrapped workpieces, etc., and achieve the effect of prolonging tool life, improving surface finish and eliminating vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

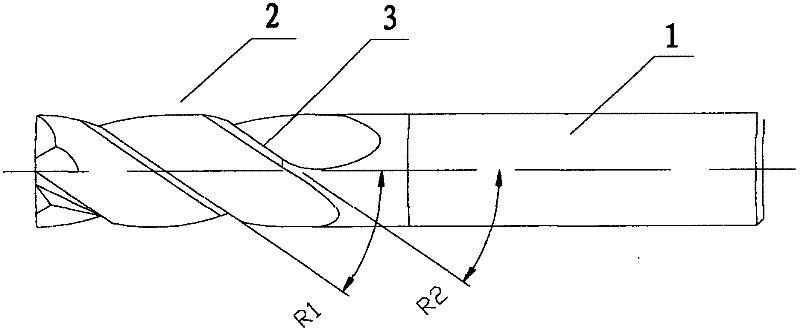

[0014] Such as figure 1 , 2 As shown, this embodiment is a four flute helical end mill with X-CEED coating on its surface. The four flute helical end mill includes a shank 1 and a blade 2. The blade 2 is provided with multiple For one parabolic side edge 3, the helix angles of the plurality of side edges 3 are different, and the distances between adjacent side edges in the plurality of side edges 3 are different.

[0015] Specifically:

[0016] Such as figure 1 As shown, the helix angle R1 of some side cutting edges 3 is 41°, and the helix angle R2 of some side cutting edges 3 is 38°. By analogy, the helix angles of the four side cutting edges 3 are different, and the difference between the helix angles The difference is 3 degrees.

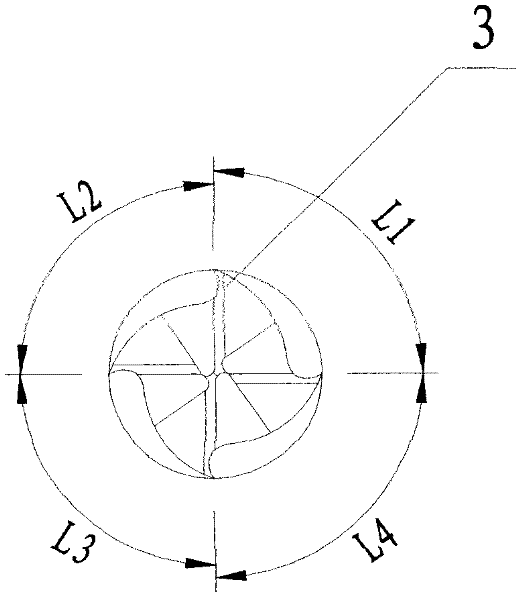

[0017] Such as figure 2 As shown, the distances L1, L2, L3, and L4 between adjacent side edges are represented by angles, and the specific values are as follows: L1=84°, L2=87°, L3=93°, L4=96°, that is, adjacent side edges The pitches are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com