An online monitoring method for turning stability of CNC machine tools

A numerical control machine tool and stability technology, applied in the monitoring field, can solve the problems of inconvenient signal monitoring, affecting the normal processing of the machine tool, and troublesome sensor installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

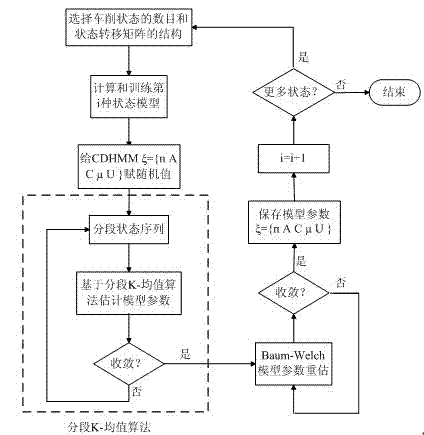

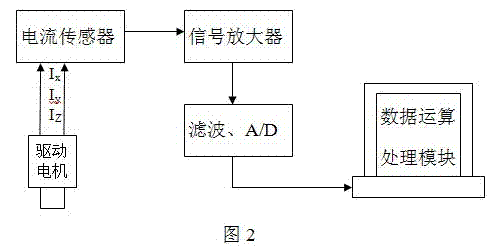

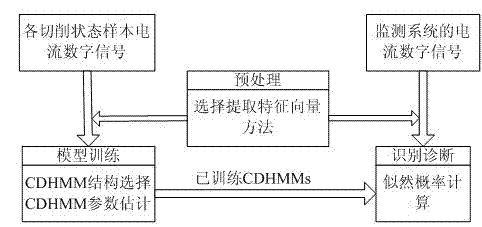

[0021] The on-line monitoring method of turning stability of the present invention realizes on-line monitoring of turning stability by acquiring the current signal of the drive motor of the machine tool, going through a series of signal processing and feature extraction selection processes, and finally through the judgment process of the monitoring model.

[0022] The method of the invention utilizes the CDHMM model and the model library to analyze and calculate the collected data to realize the turning stability monitoring of the numerical control machine tool. First, initialize the parameters of the CDHMM model and generate the model library through the following steps. The process is as follows: figure 1 shown.

[0023] (1) Use the Hall current sensor to measure the three-phase output current of the drive motor of the CNC machine tool respectively, as a sample current signal;

[0024] The sample current signal obtained through step (1) should include three cutting states: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com