Manufacturing process for conductive carrying belt of electronic element

An electronic component and manufacturing process technology, applied in the manufacturing process field of electronic component carrier tape, can solve the problems of low product quality and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A manufacturing process of a carrier tape for conductive electronic components, comprising the following steps in turn: (1) making a polymer raw material into a thin film fluid, and processing the film fluid into an intermediate product of the carrier tape with pockets through a convex-concave mold, the polymerization The raw material of the product is a mixture of general-purpose polystyrene and conductive carbon black. According to the mass ratio, general-purpose polystyrene is 70% and conductive carbon black is 30%. The intermediate product of the carrier tape is punched and trimmed to obtain the finished product of the carrier tape for conductive electronic components.

[0020]In the above step (1), the polymer raw material is made into a film fluid through an extruder, and the convex and concave molds move in the same direction as the film exiting direction of the extruder and the moving speed is the same as the film exiting speed of the extruder, and the convex and...

Embodiment 2

[0027] A manufacturing process of a conductive electronic component carrier tape, the process steps are the same as in Example 1, the difference is that the proportions of general-purpose polystyrene and conductive carbon black in the polymer raw materials are different, and according to the mass ratio, the general-purpose polystyrene 80% styrene, 20% conductive carbon black, and the temperature of the convex and concave molds for film processing is controlled at about 220°C. The flow velocity of the film fluid is 18 m / min, and the downward movement speed of the convex-concave mold is consistent with the flow velocity of the film.

Embodiment 3

[0029] A manufacturing process of a conductive electronic component carrier tape, the process steps are the same as in Example 1, the only difference is that the proportion of general-purpose polystyrene and conductive carbon black in the polymer raw materials is different, and the general-purpose polystyrene is different in terms of mass ratio. Polystyrene is 90%, conductive carbon black is 10%, and the temperature of the convex and concave molds for film processing is controlled at about 225°C. The flow velocity of the film fluid is 22 m / min, and the downward movement speed of the convex-concave mold is consistent with the flow velocity of the film.

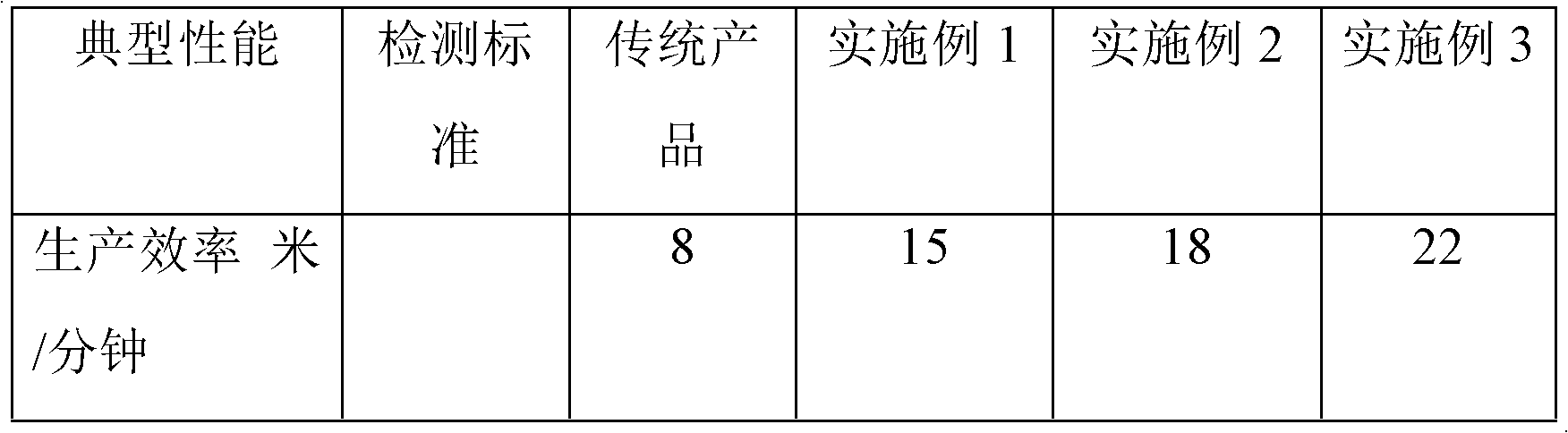

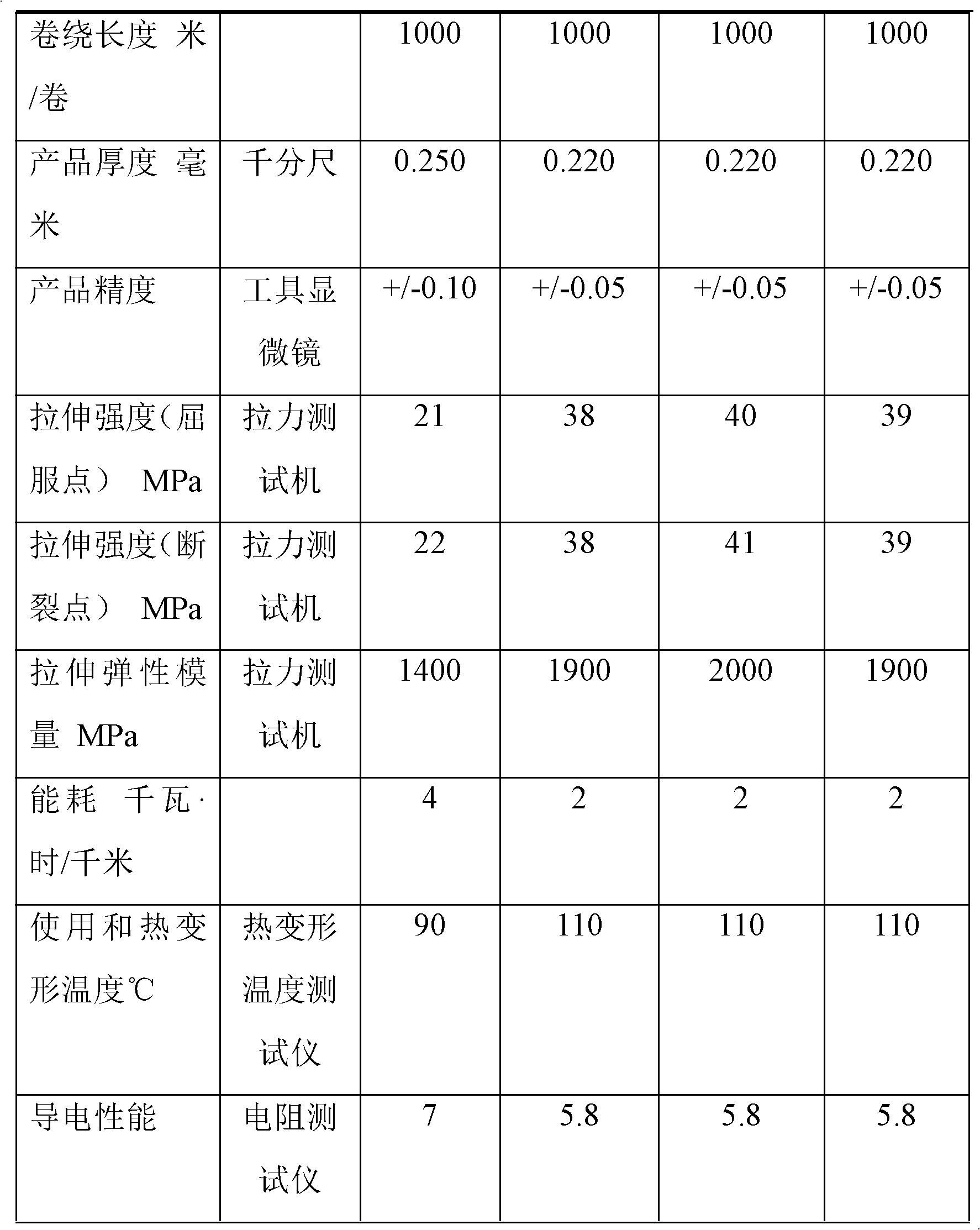

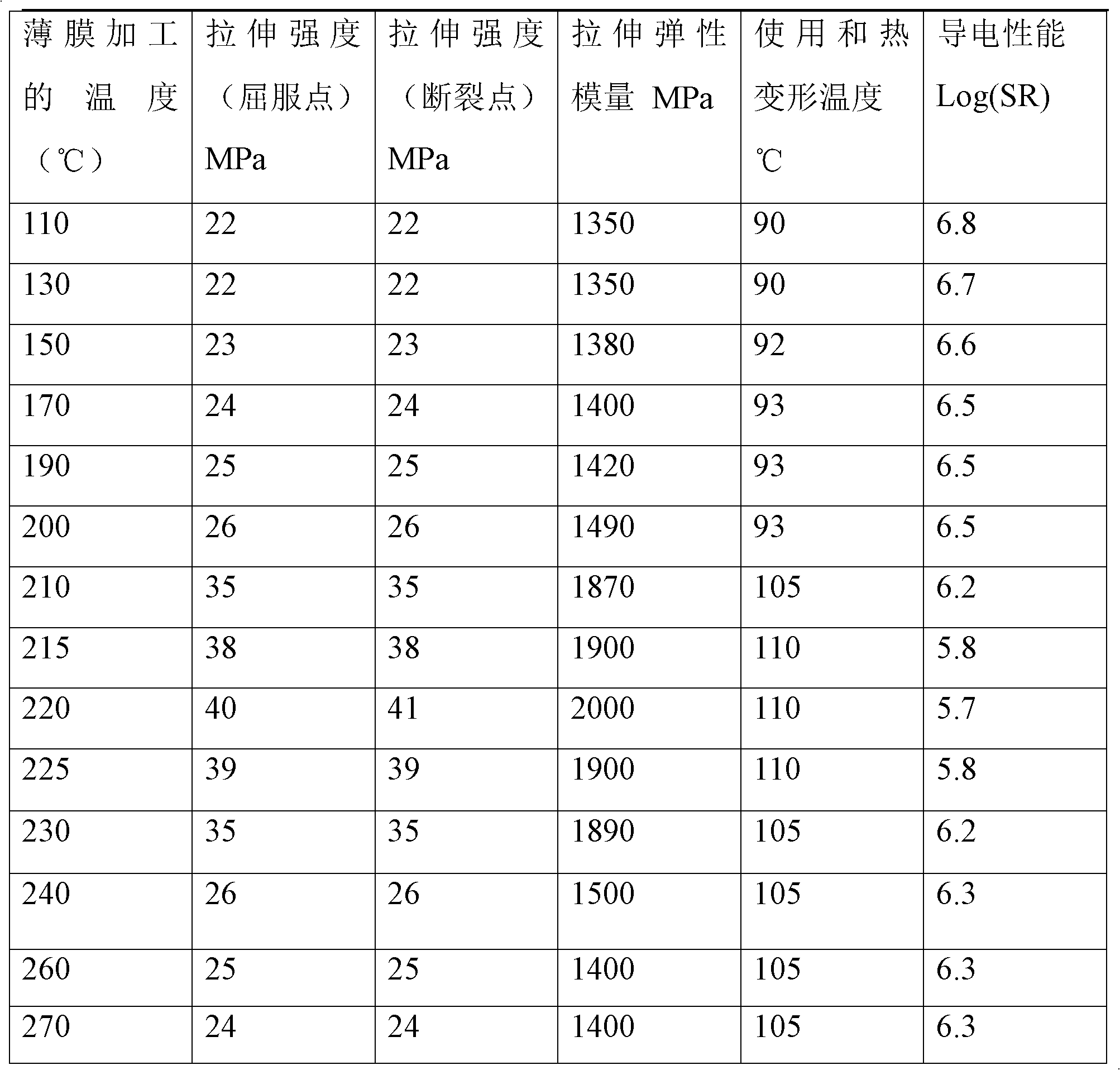

[0030] Following table is the data comparison of traditional product and 3 embodiments of this patent.

[0031]

[0032]

[0033] The above three embodiments are only preferred implementation modes of the present invention. Compared with the traditional two-stage process and intermittent equipment to produce electronic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com