A diamond saw blade cold press forming machine

A technology of cold-pressing forming machine and diamond saw blade, applied in punching machine, press machine, manufacturing tool, etc., can solve the problems of high labor intensity, large force surface, and inability to fine-tune, so as to reduce labor intensity and prolong mold life. , the effect of small force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

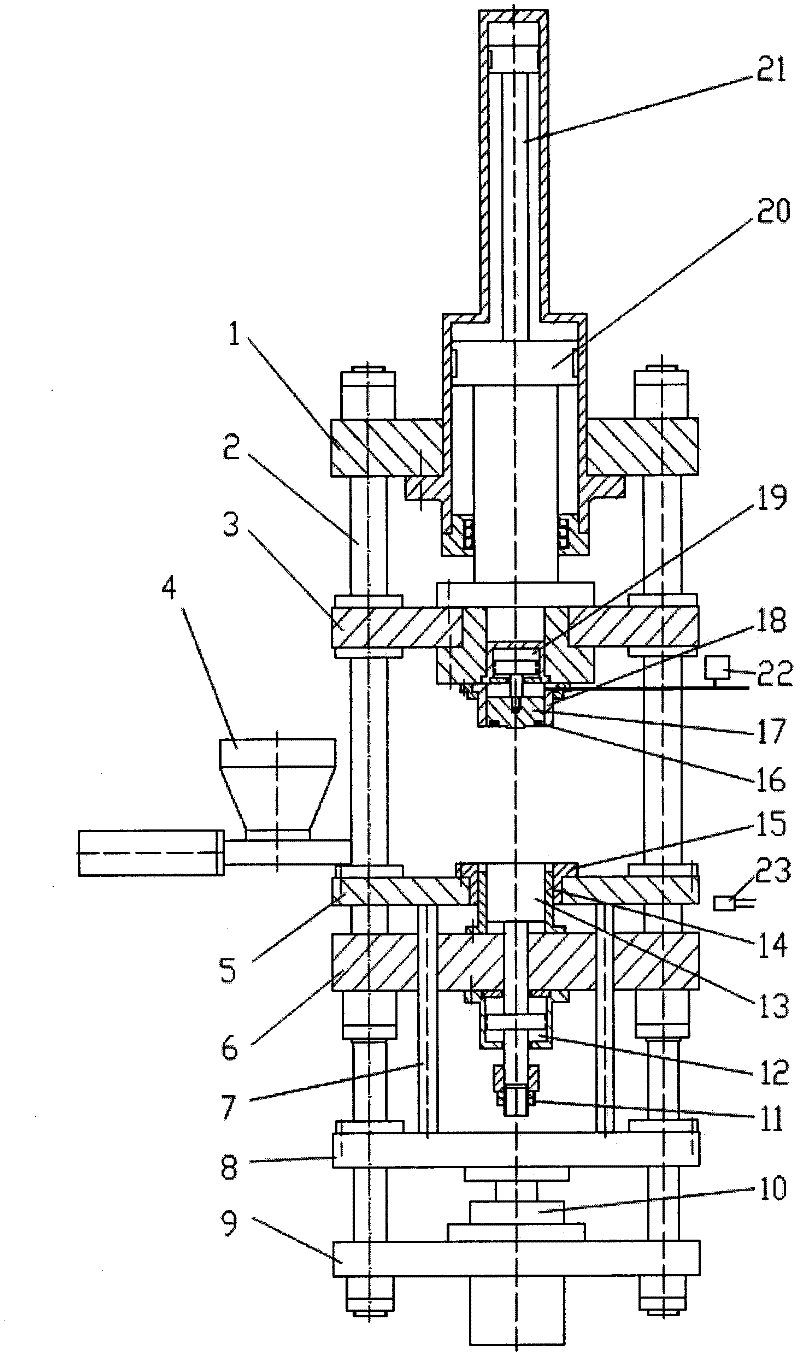

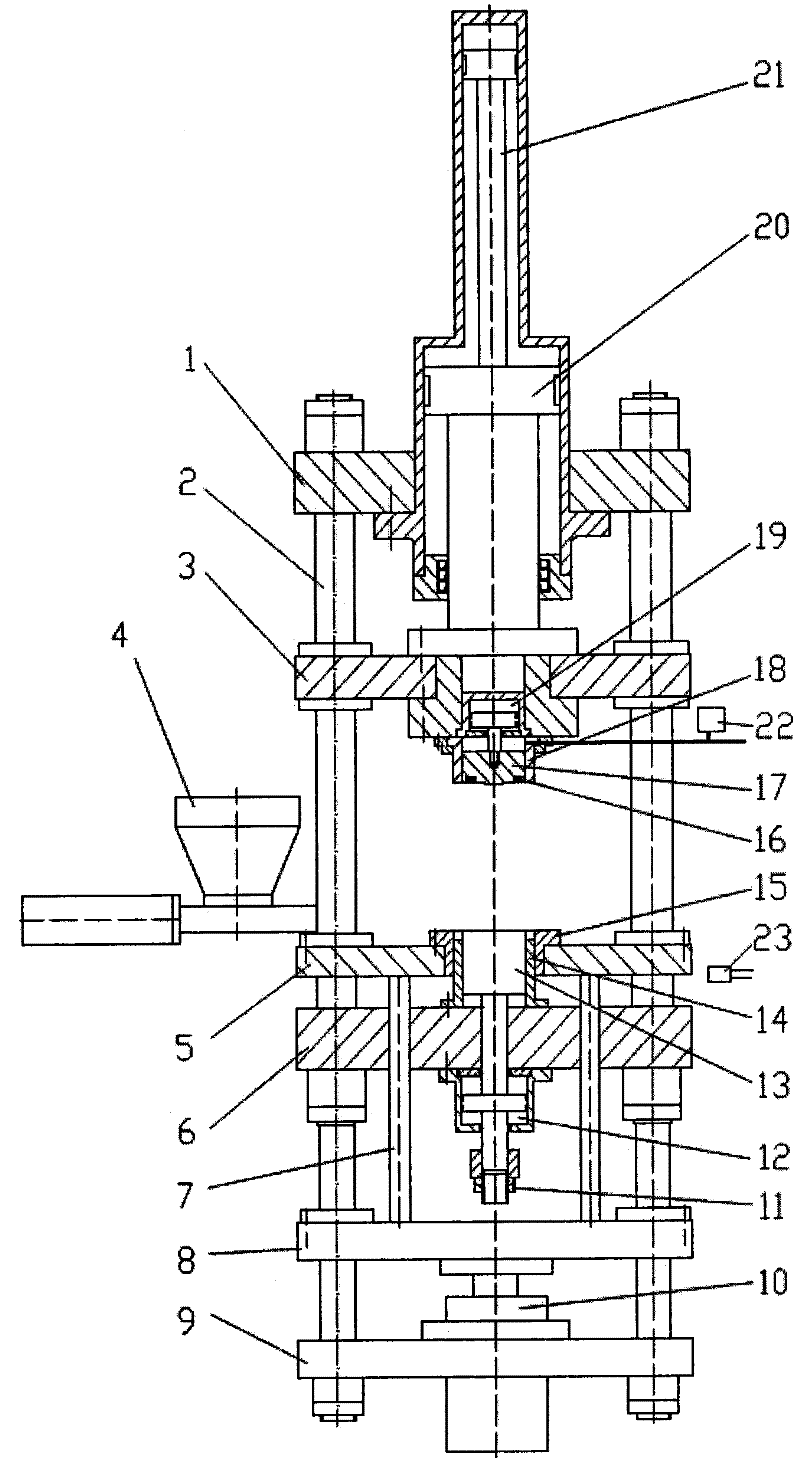

[0013] Depend on figure 1 It is known that the diamond saw blade cold press forming machine of the present invention is composed of a frame, a guide column 2, a connecting rod 7, an upper mold and a lower mold, and the frame is composed of an upper fixed plate 1, a middle fixed plate 6, and a lower fixed plate 9 Composed and fixed by four guide posts 2; the upper slide plate 3, the middle slide plate 5 and the lower slide plate 8 are movably connected on the guide post 2, and they are between the upper fixed plate 1, the middle fixed plate 6 and the lower fixed plate 9; the main The oil cylinder 20 is installed on the upper fixed plate 1, and the piston rod is connected with the upper slide plate 3; the main oil cylinder 20 is provided with a small-diameter oil cylinder 21 as a fast oil cylinder, and the cylinder barrel of the small-diameter oil cylinder 21 is connected to the cylinder tail of the main oil cylinder 20, and the piston The rod is connected to the piston tail of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com