A treatment method for coal gasification ash water reuse

A treatment method and a coal gasification technology, applied in the field of water treatment, can solve the problems of increasing the discharge of wastewater from enterprises, failing to meet energy conservation and emission reduction, and being unfavorable for environmental protection, and achieve the effects of good softening effect, low treatment cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

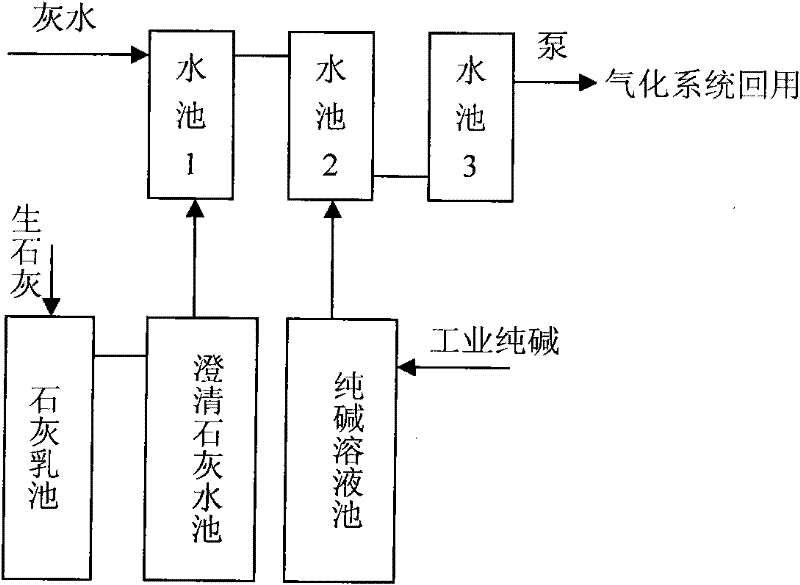

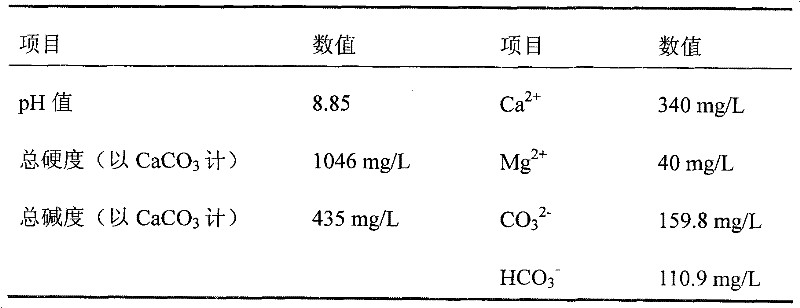

[0032] First, at room temperature (20-25°C), add quicklime powder for industrial use into a lime milk pool filled with gray water, stir well, and prepare a lime emulsion with a concentration of 5% by mass, and let it stand for a long enough time Afterwards, the upper layer saturated clarified lime water solution overflows to the clarified lime water pool, and the saturated clarified lime water is pumped to the pool 1 to carry out softening reaction; in the soda ash solution pool, industrial soda ash is mixed with a concentration of 5% Na in the soda ash solution pool. 2 CO 3 The solution is pumped to pool 2 for softening reaction, and overflows to pool 3 for full sedimentation and filtration. The ash water temperature in each ash water pool is 55-70°C, which is close to the water temperature of the ash water tank of the Texaco gasification process. The overflowed gray water can be reused as circulating water, and the bottom flow of each gray water pool is pumped to the storag...

Embodiment 2

[0039]The softening effect measurement method and gray water are the same as in Example 1.

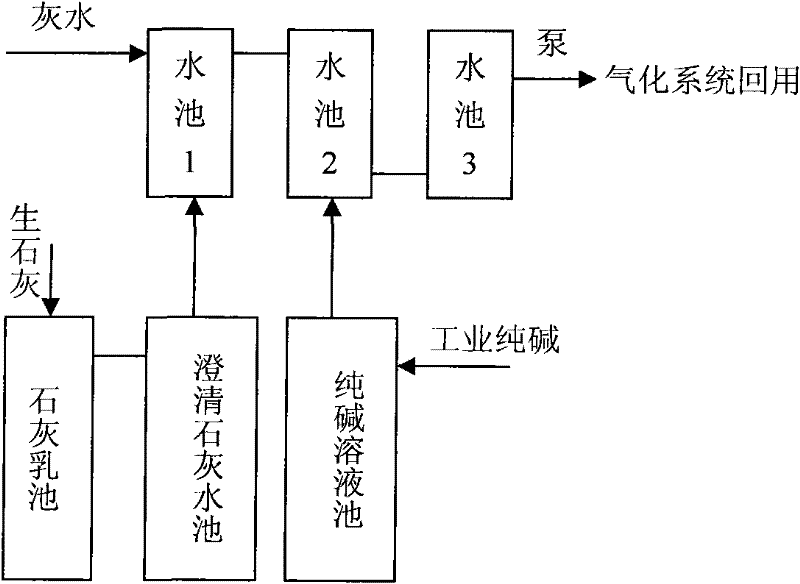

[0040] The quicklime is formulated into a lime emulsion with a mass percentage concentration of 15% at a temperature close to the boiling point of water, which is beneficial to the digestion of quicklime and the improvement of softening effect; the lime emulsion is directly pumped to the gray water pool 1 for softening reaction; in the soda ash solution pool The industrial soda ash is formulated into Na with a concentration of 10% by mass percentage 2 CO 3 The solution is pumped to the gray water pool 2 for softening reaction, and overflows to the gray water pool 3 for full sedimentation and filtration. The ash water temperature in each ash water pool is 55-70°C, which is close to the water temperature of the ash water tank of the Texaco gasification process. The overflowed gray water can be reused as circulating water, and the bottom flow in each gray water pool is sent to the stora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com