The preparation technology of 2-methyl-4-chlorophenoxyacetic acid dimethylamine salt

A chlorophenoxyacetic acid dimethylamine salt and a preparation process technology, which is applied in the field of preparation of 2-methyl-4-chlorophenoxyacetic acid dimethylamine salt, can solve the problems of precipitation and low use efficiency, and achieve no precipitation , low cost, and the effect of process route optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

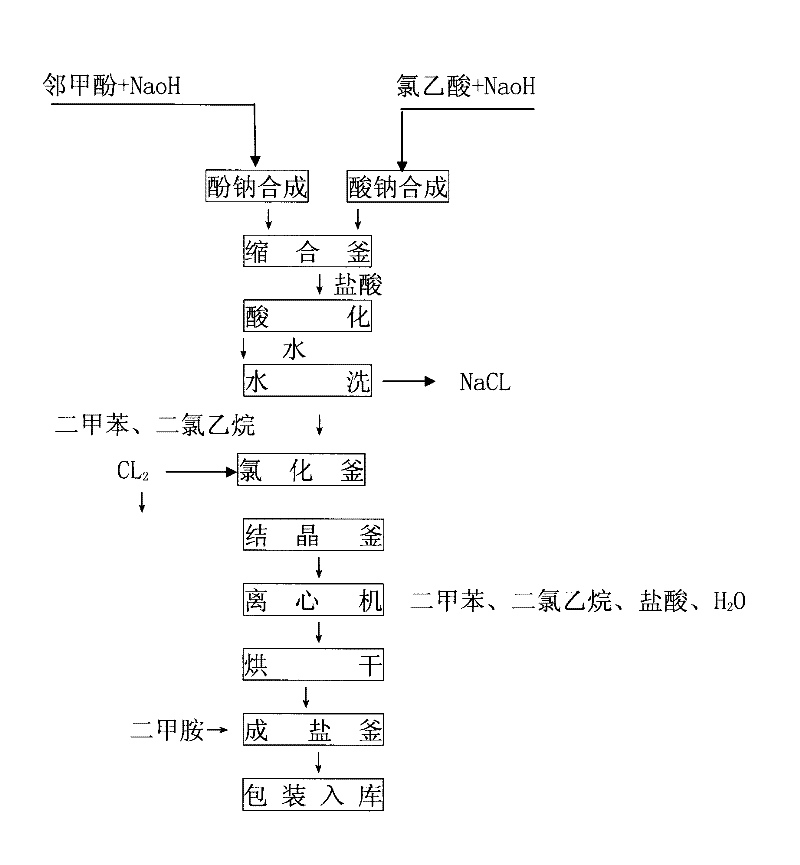

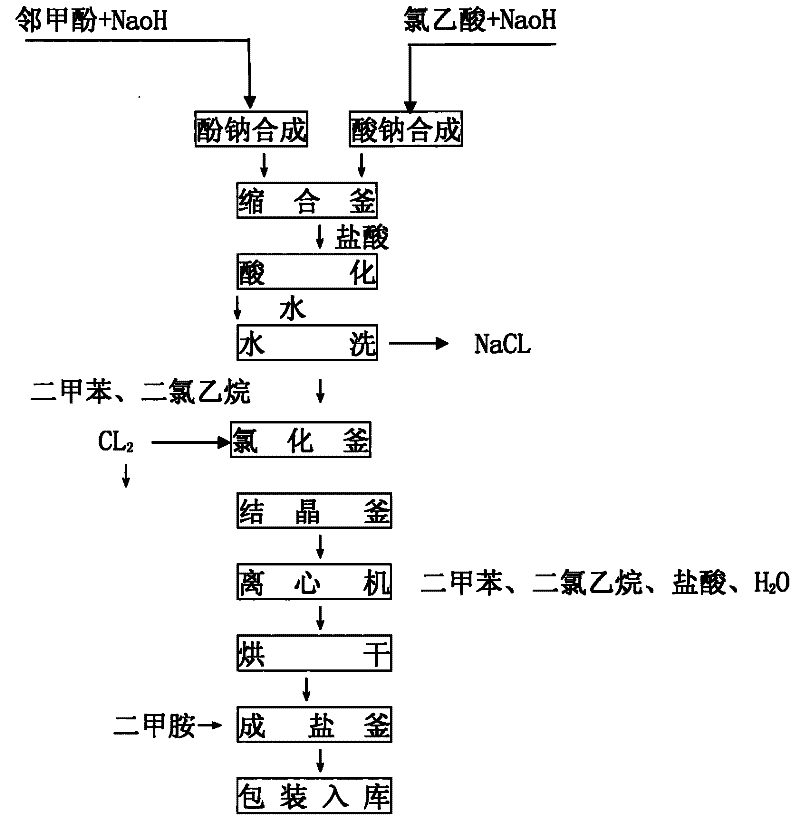

Image

Examples

Embodiment 1

[0016] 1. Add chloroacetic acid to the reaction kettle, add 30% caustic soda solution dropwise to neutralize the reaction, control the temperature at 5°C, and the pressure at normal pressure. When the pH value of the material is 7-8, it is the end of the reaction and sodium chloroacetate is generated;

[0017] 2. Add o-cresol to another reactor, control the temperature at 25°C, the pressure at normal pressure, and the reaction time for 35 minutes. Add 30% caustic soda solution dropwise to react to generate o-cresol sodium. After the reaction, heat preservation is performed;

[0018] 3. Add the sodium chloroacetate from the previous kettle to the o-cresol sodium reaction kettle of the next kettle through the metering tank, control the temperature at 125°C, the reaction time for 9 hours, and the pressure at normal pressure to produce 2 methylbenzene through condensation reaction Sodium oxyacetate;

[0019] 4. Transfer the above reaction materials to the chlorination reactor, add hydroc...

Embodiment 2

[0023] 1. Add chloroacetic acid to the reaction kettle, add 30% caustic soda solution dropwise to neutralize the reaction, control the temperature at 25°C, and the pressure at normal pressure. When the pH value of the material is 7-8, it is the end of the reaction and sodium chloroacetate is generated;

[0024] 2. Add o-cresol to another reactor, control the temperature at 40°C, the pressure at normal pressure, and the reaction time for 25 minutes. Add 30% caustic soda solution dropwise to react to generate o-cresol sodium. After the reaction, heat preservation is performed;

[0025] 3. Add the sodium chloroacetate from the previous kettle to the o-cresol sodium reaction kettle in the next kettle through the metering tank, control the temperature to 130°C, the reaction time is 8 hours, and the pressure is normal pressure, and 2 methylbenzene is produced through condensation reaction Sodium oxyacetate;

[0026] 4. Transfer the above reaction materials to the chlorination reactor, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com