Preparation method of duloxetine key intermediate

A thienyl and methylamino technology, applied in the field of organic synthesis, can solve the problems of difficult separation and purification, unfavorable long-term use, cumbersome steps, etc., and achieves the effects of fewer reaction steps, economical savings, and simple process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

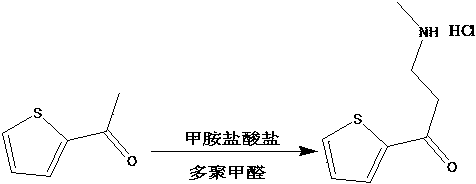

[0020] Example 1 Preparation of 3-N-methylamino-1-(2-thienyl)-1-acetone hydrochloride

[0021] Put 20ml of 2-acetylthiophene into a three-necked flask, add 160-200ml of methanol, 0.01-0.02g of concentrated hydrochloric acid, 16.2-25.7g of methylamine hydrochloride, and 6.8-8.6g of paraformaldehyde, and heat to reflux for reaction. After 9-10 hours, Crystals were precipitated, filtered, and recrystallized with pure water to obtain 32-33 g.

Embodiment 2

[0022] Example 2 Preparation of 3-N-methylamino-1-(2-thienyl)-1-acetone hydrochloride

[0023] Put 20ml of 2-acetylthiophene into a three-necked flask, add 160-200ml of ethanol, 0.01-0.02g of concentrated hydrochloric acid, 16.2-25.7g of methylamine hydrochloride, and 6.8-8.6g of paraformaldehyde, and heat to reflux for reaction. After 8-9 hours, Crystals were precipitated, filtered, and recrystallized with pure water to obtain 34-35 g.

Embodiment 3

[0024] Example 3 Preparation of 3-N-methylamino-1-(2-thienyl)-1-acetone hydrochloride

[0025] Put 20ml of 2-acetylthiophene in a three-necked flask, add 160-200ml of ethanol, 0.01-0.02g of concentrated sulfuric acid, 16.2-25.7g of methylamine hydrochloride, and 6.8-8.6g of paraformaldehyde, and heat to reflux for 9-10 hours. Crystals were precipitated, filtered, and recrystallized with pure water to obtain 35-36 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com