A method of dealing with bridge head jumping based on portal cement mixing wall

A technology of bridge head jumping and cement mixing piles, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of large proportion of repair materials and large foundation settlement, so as to reduce construction cost, increase bearing capacity and shear strength, reduce The effect of small lateral deformations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

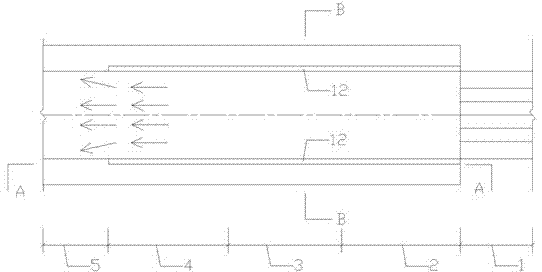

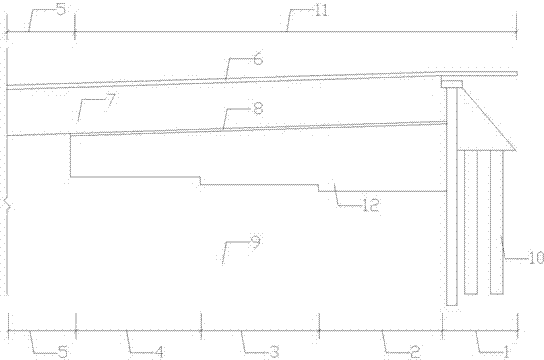

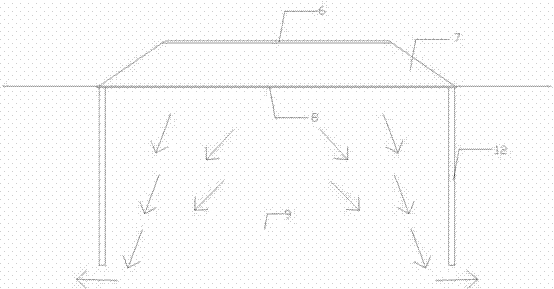

[0025] Embodiment 1, the transition section between highway abutment 1 and the embankment in a certain soft soil area is 50m long, the filling height is 3m, the road width is 26.5m, and the foundation 9 has a strong structure of 3 layers with a thickness of 11.9-18.3m. Constructed of soft clay with high sensitivity and great compression.

[0026] The processing range of portal cement mixing wall 11 is 30m in length, and the cement mixing piles are in a single row. The wall treatment section 4 is taken as 9m, the pile diameter is uniformly 500mm, and the lap length is uniformly 100mm; the geomembrane used as the horizontal anti-seepage layer adopts the form of a single-layer geomembrane anti-seepage layer with a thickness of 1mm.

[0027] At the abutment and the embankment adjacent, the settlement after 2500 days after construction is only 74mm, meeting the requirement of post-construction differential settlement within 100mm. By repairing the road surface during the overh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile length | aaaaa | aaaaa |

| Pile diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com