An atmospheric hot water boiler

A hot water boiler and boiler technology, applied in the field of boilers, can solve the problems of short flue gas flow, large water capacity, small heating area, etc., and achieve the effects of increasing circulation flow, large flow of hot water, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

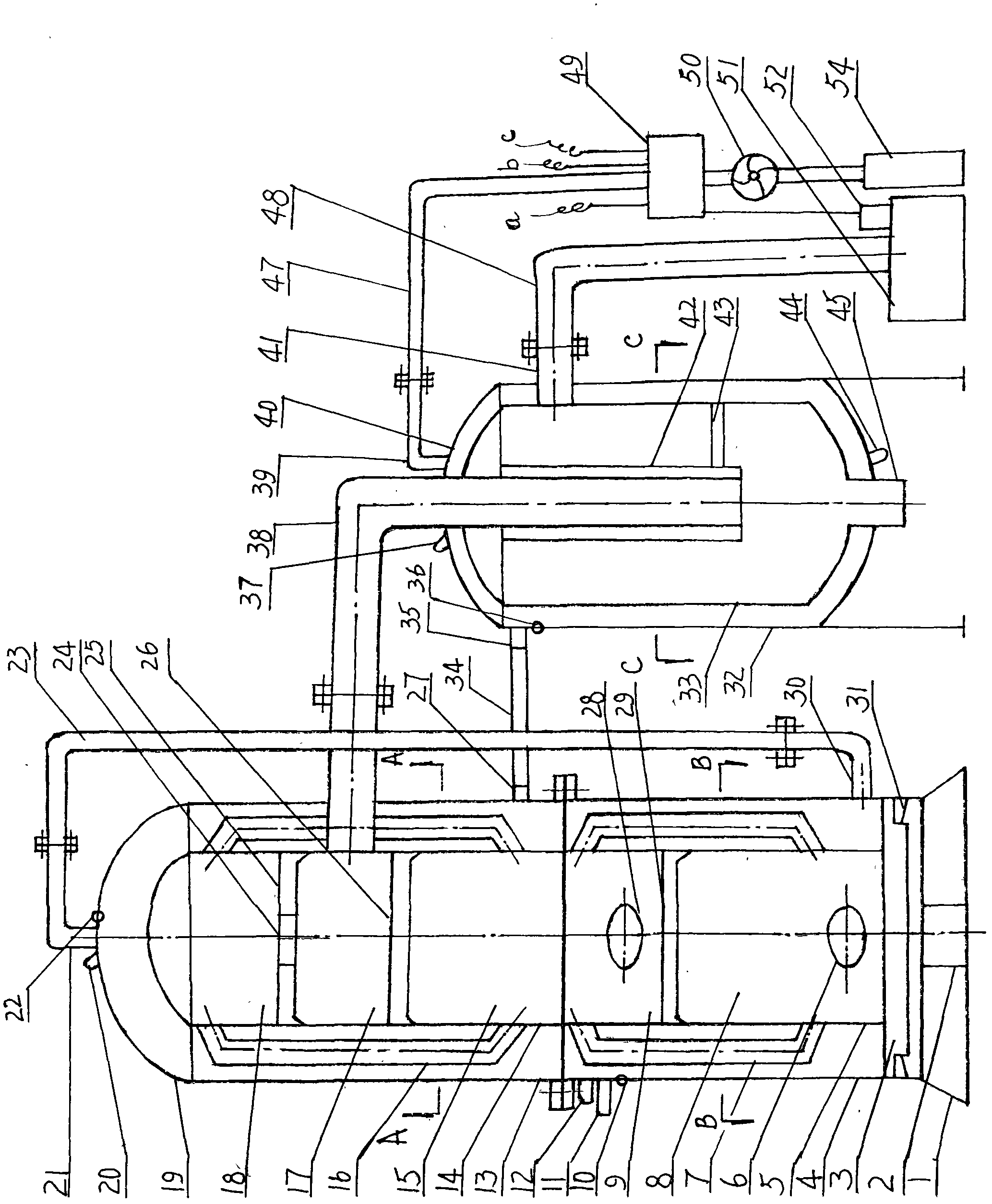

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

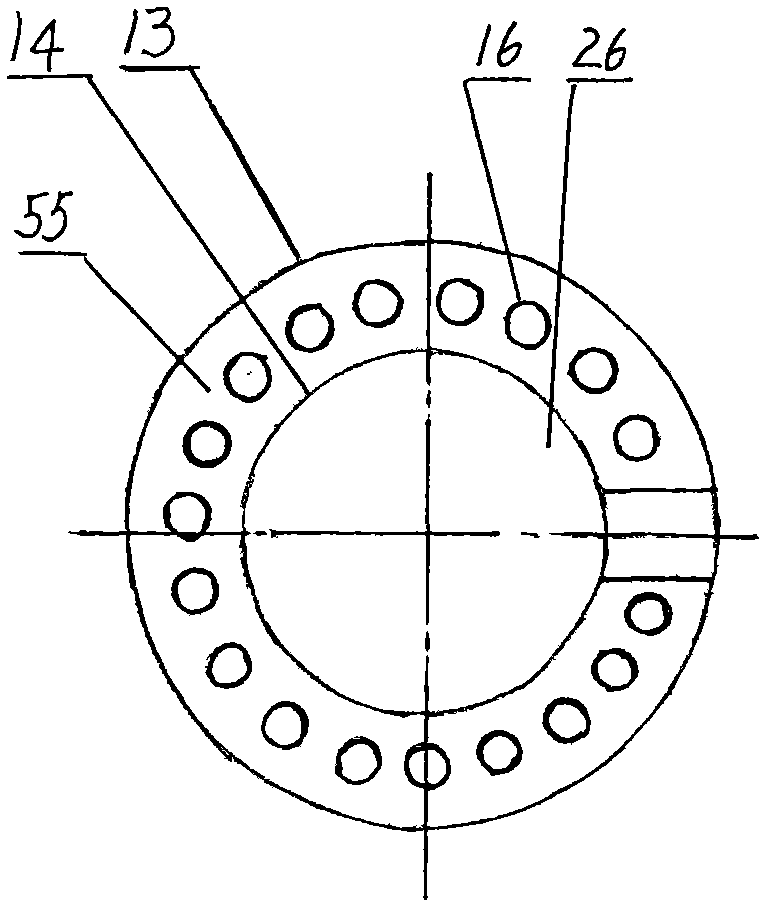

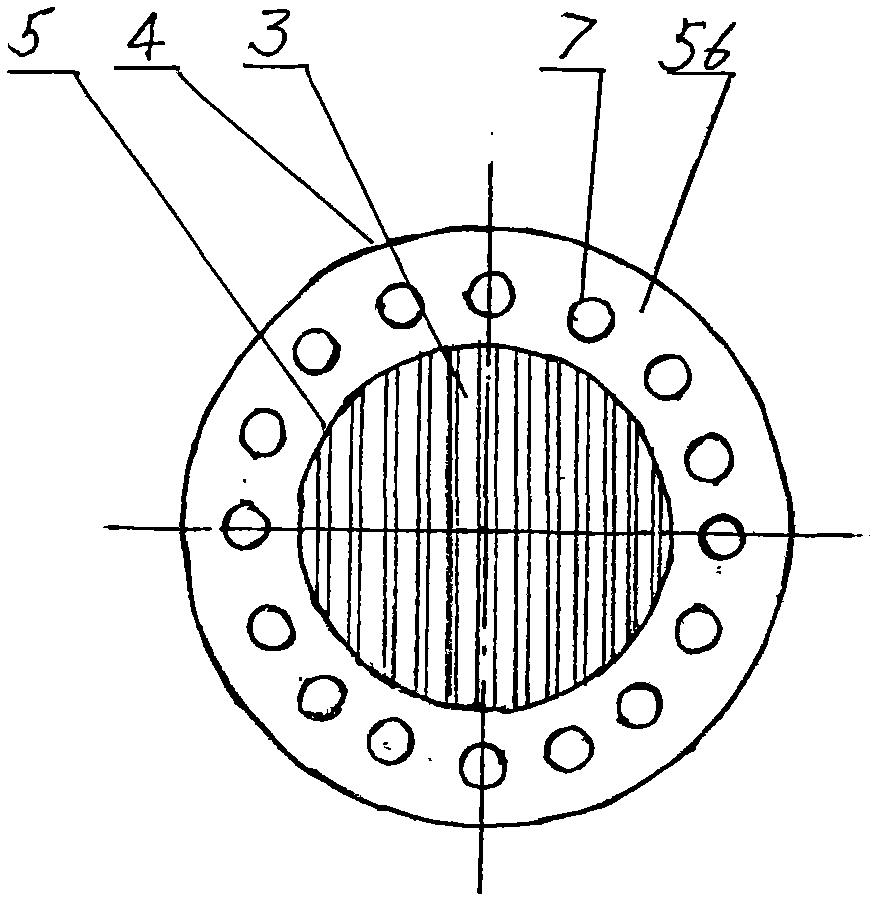

[0017] Figure 1 to Figure 4Among them, the main body of the boiler is composed of a detachable connection between the lower body of the boiler and the upper body of the boiler and the heat exchanger. The boiler lower body is connected to the fire grate 3, and the fire grate 3 is connected to the boiler base 1 through the fire grate bracket 31. The boiler base 1 is provided with a slag outlet 2, and the boiler lower body is provided with a coal filling port 6. The lower body of the boiler is composed of a lower body shell 4 and a lower inner liner 5 fitted therein. The cavity 56 formed between the lower body shell 4 and the lower body tank 5 constitutes the boiler lower body water circulation channel, and the lower body vertical fire pipes 7 are distributed in the cavity 56 to form a secondary combustion chamber. The lower body fire retardan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com