Contact wire online automatic detection system equipment

An automatic detection and contact wire technology, applied in signal transmission systems, measuring devices, instruments, etc., can solve problems such as insufficient measurement positioning and reference stability, weak clamping force, and inability to meet the requirements of contact wire detection, etc., to achieve Economical use, safe operation, accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

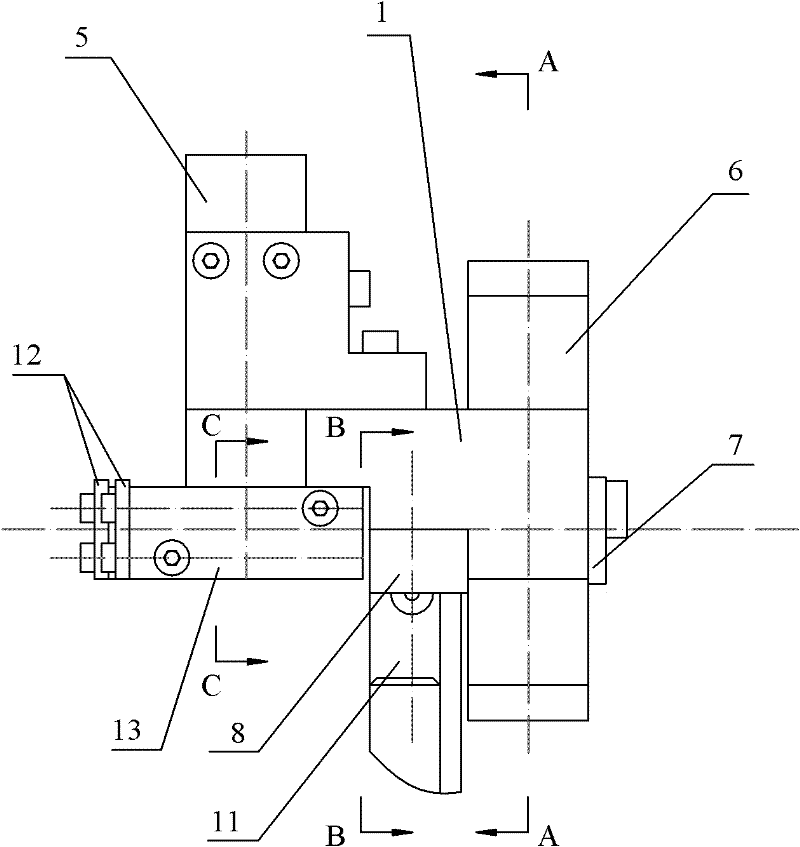

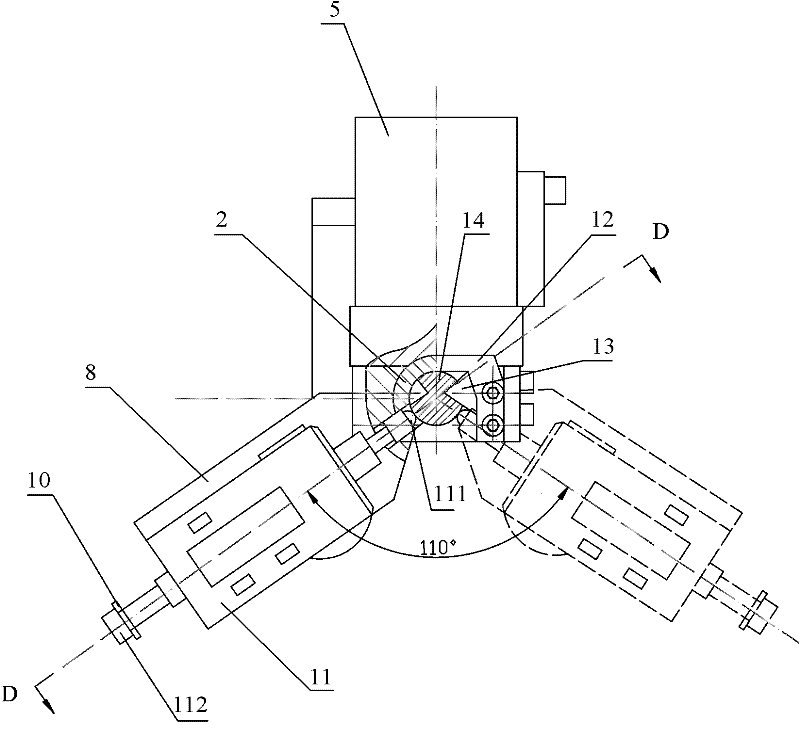

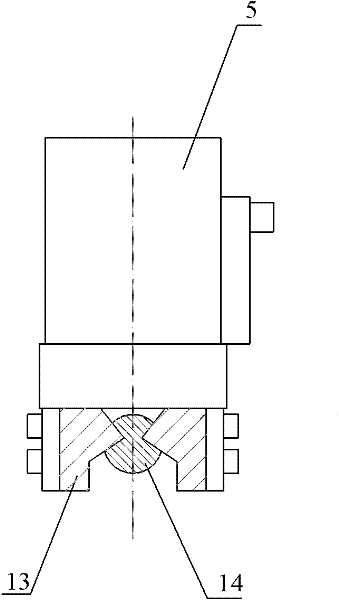

[0051] Figure 1 to Figure 6 An on-line automatic detection system equipment for contact wires is given, which is composed of five major components: miniature pneumatic measuring probe assembly, portable miniaturized air control system, portable program logic electronic control system, wireless signal transmission system, data storage and analysis printing system.

[0052] 1. Miniature pneumatic measuring probe assembly:

[0053] Miniature pneumatic measuring probe assembly (such as Figure 1 to Figure 5 shown), it includes the instrument housing 1, on the left side of the instrument housing 1 (as shown in the front view figure 1 Shown) is provided with positioning micro-cylinder 5, and the cylinder body of positioning micro-cylinder 5 is connected with instrument housing 1 with fasteners. The lower part of the positioning miniature cylinder 5 is provided with a translation jaw pair 13 composed of 2 symmetrical (and relatively moving) translation jaws. The direction center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com