A kind of ecological harvesting method of Daphnia algae

A harvesting method, the technology of Daphnia algae, applied in the field of environmental technology and renewable energy, can solve the problems of high cost of microalgae biodiesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The invention provides a high-yield cleaning method for ecologically energy-saving harvesting of Daphnia algae with nutrient-rich water. It is based on the existing research results and technology of extracting bioenergy from microalgae as raw material and constructing daphnia algae system, and extracting bioenergy from daphnia, by using nutrient-rich water as the culture medium to construct high-yield and stable daphnia algae The system harvests daphnia at a certain rate and extracts bioenergy from daphnia.

[0022] 1. Construction of Daphnia algae ecosystem in nutrient-rich water:

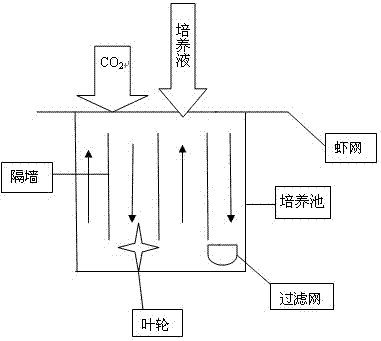

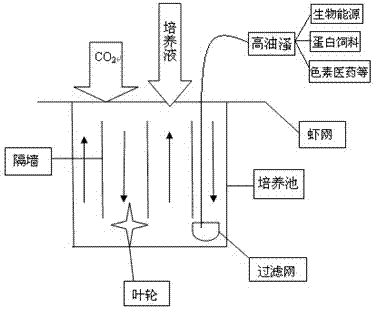

[0023] see figure 1 , figure 2 , Daphnia algae ecosystem consists of culture pool, culture solution, CO 2 Composed of gas and shrimp nets, the cultivation tank is divided into water channels of about 2.0±0.1 meters by a partition wall, and the water depth is 1.5-2 meters. The material of the cultivation tank and the partition wall is made of transparent glass or cement, and an impelle...

Embodiment 2

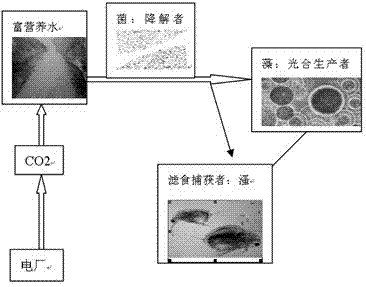

[0032] In order to simplify management, reduce costs and improve system output and ecological stability, the present invention uses native fungi, algae and daphnia in industrial sewage and domestic sewage, and algae and daphnia with high fat content can also be used. However, species such as fish and shrimp in the cultivation tank should be removed before cultivation (especially before supplementary water enters the pond), so that a food chain can be formed in the system (see image 3 ), the algal flea food chain system is suitable for both seawater and freshwater water bodies, the difference is that the seawater system needs to use marine microalgae and daphnia suitable for the local environment.

[0033] Table 1 analyzes the differences in various indicators between the Daphnia algae harvesting system and the single microalgae biomass cultivation system, confirming that the method of the present invention can greatly improve the sewage purification efficiency, increase energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com