One-step rubber mixing process for tires using trans isoprene rubber tpi

A trans isoprene rubber and rubber mixing technology, which is applied in the field of polymer materials and production automation, can solve the problems of increasing intermediate links, time-consuming and labor-intensive, and increased production costs, so as to improve production efficiency, prevent aging, and improve heat resistance and flex cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

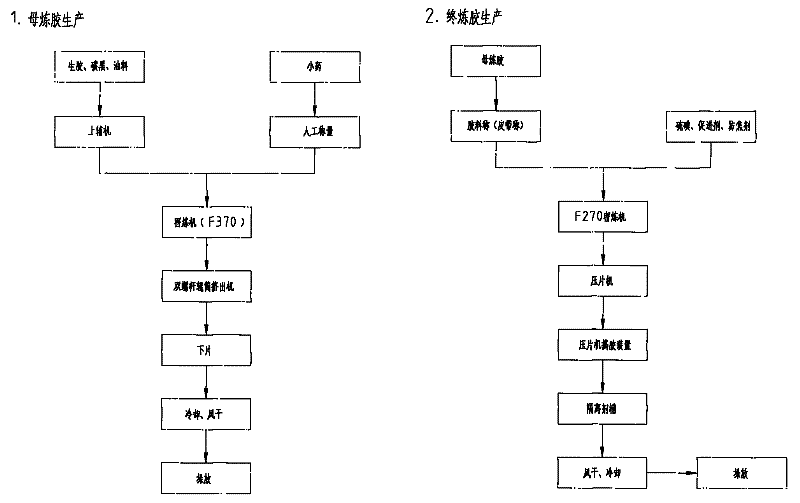

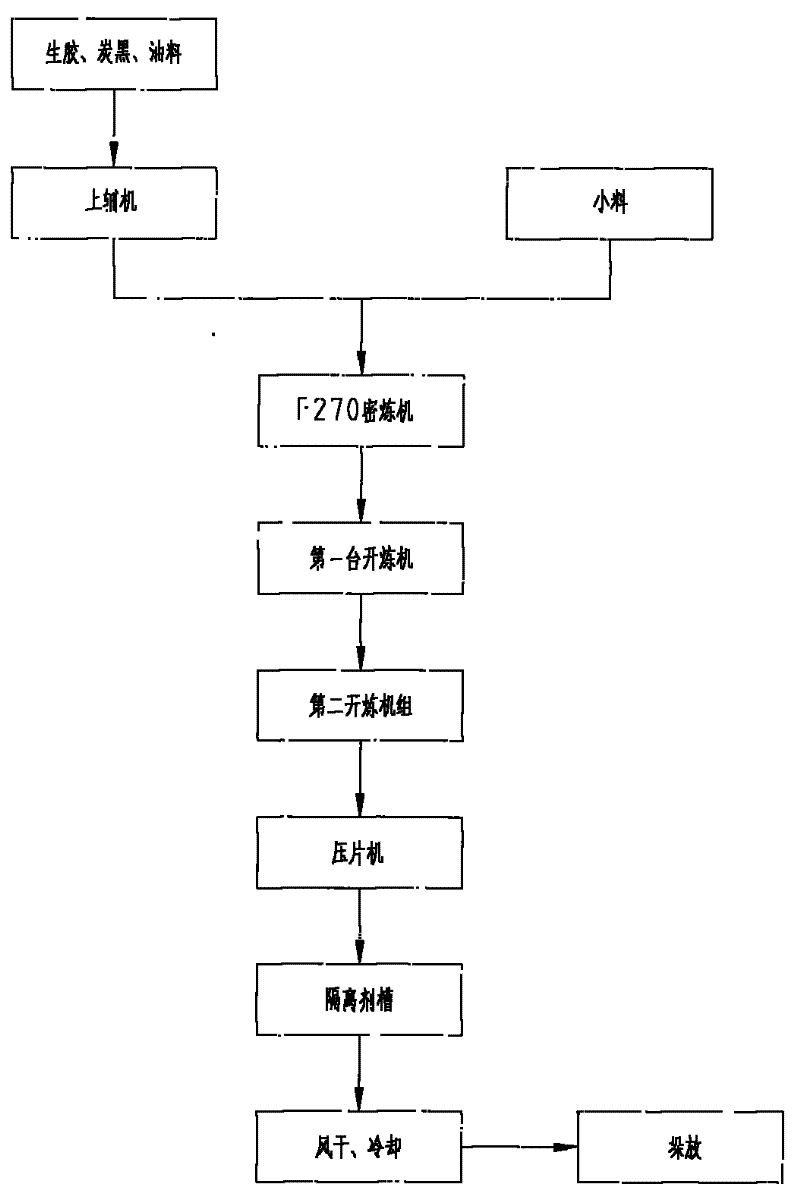

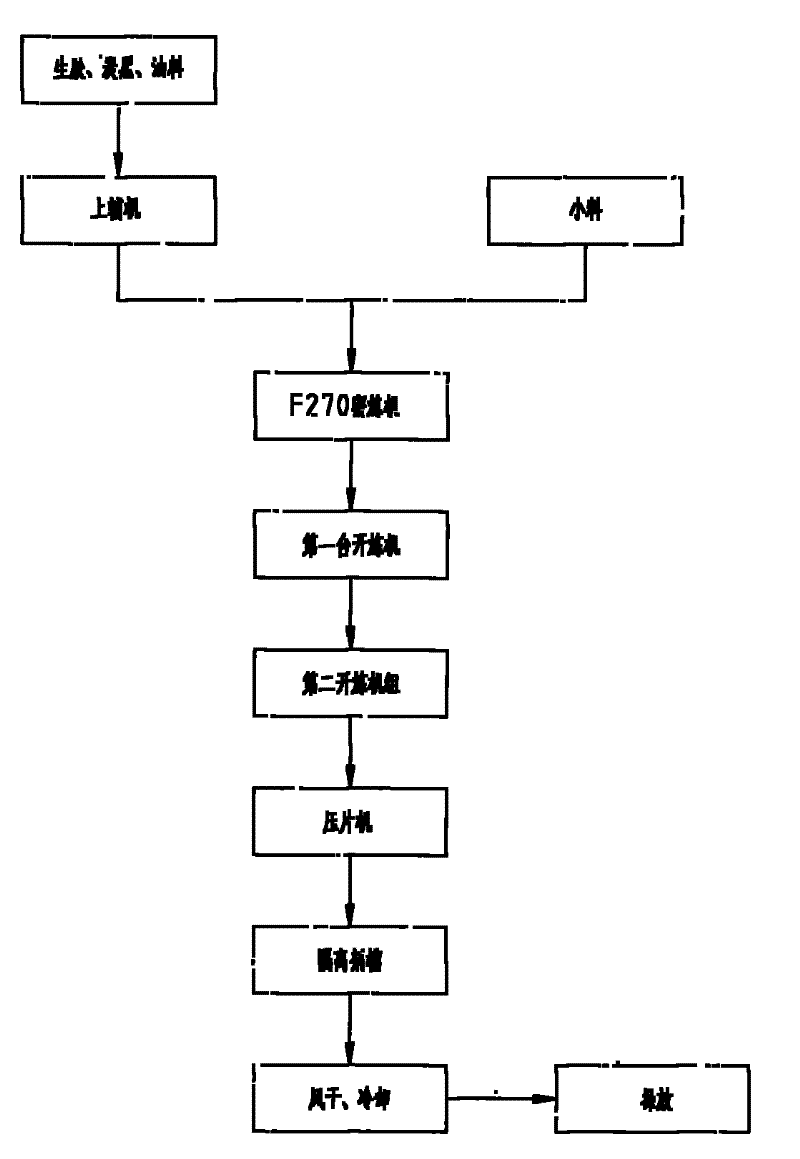

[0030] Example 1, such as figure 2 As shown, the rubber compound formula using the primary rubber mixing process of tires contains the following main components according to the mass ratio:

[0031] Natural rubber, 54%;

[0032] Trans isoprene rubber TPI, 15%;

[0033] Carbon black N234, 23%;

[0035] Stearic acid, 1.0%;

[0036] Antiaging agent 6PPD, 1.0%;

[0037] Antiaging agent RD, 1.3%;

[0038] Sulfur, 1.3%;

[0039] Accelerator TBBS, 0.5%;

[0040] Anti-scorch agent CTP, 0.2%;

[0041] Microcrystalline Wax, 0.2%.

[0042] The one-time rubber mixing process adopted is to put the trans isoprene rubber TPI and natural rubber into the internal mixer together, and the carbon black, zinc oxide, stearic acid and anti-aging agent in the rubber formula are all mixed in the internal mixer. input into the machine;

[0043] When the mixing temperature in the internal mixer reaches 160-165°C, the rubber material is discharged into the first sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com