A kind of configuration and coating method of aluminum foil pre-coated nano conductive carbon primer

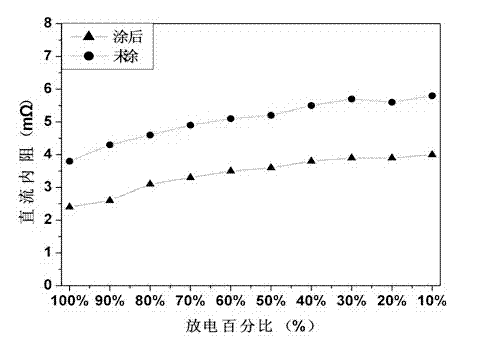

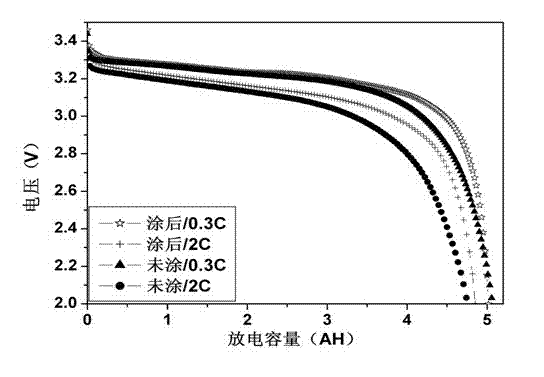

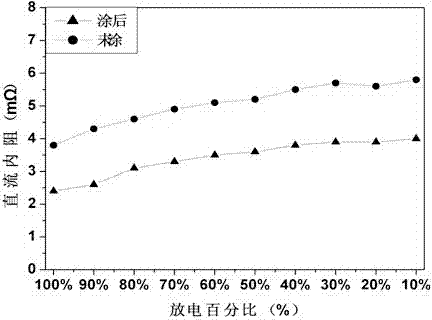

A technology of nano-conduction and primer liquid, which is applied in the direction of surface coating liquid devices, conductive adhesives, coatings, etc., which can solve the problem of unimproved conductivity of active materials and current collector aluminum foil, lithium iron phosphate active materials and Poor bonding of current collector aluminum foil, affecting battery rate performance, cycle performance and other issues, to achieve the effect of high compaction density, good conductivity and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The configuration of the aluminum foil pre-coated nano-conductive carbon water-based primer, in terms of mass percentage.

[0025] Take by weighing 1000 grams of double distilled water aqueous solvent and 200 grams of water-based binder A and carry out mechanical stirring for 2 hours to obtain a uniform and stable binder system; add 25 grams (total mass) every 30 minutes in three times under ultrasonic dispersion conditions (75 g) powder nano-conductive carbon composite conductive agent, and then ultrasonically dispersed for 2 hours to obtain a water-based primer with a viscosity of 8000 cps. The nano conductive carbon composite conductive agent here is a mixture of 20 grams of nano conductive carbon and 5 grams of Supper P composite conductive agent. The combination of nano conductive carbon and Spper P can not only increase the conductivity of the primer solution, but also improve the flatness of the coated surface.

Embodiment 2

[0027] The configuration of the aluminum foil pre-coated nano-conductive carbon water-based primer, in terms of mass percentage.

[0028] Take by weighing 1000 grams of alcohol water-based solvent and 200 grams of water-based binder A and carry out mechanical stirring for 1 hour to obtain a uniform and stable binder system; add 18 grams every 30 minutes in three times under ultrasonic dispersion conditions (total mass is 54 g) powder nano-conductive carbon composite conductive agent, and then ultrasonically disperse for 2 hours, and finally obtain a water-based primer with a viscosity of 2000cps. The nano conductive carbon composite conductive agent here is a mixture of 15 grams of nano conductive carbon and 3 grams of Supper P composite conductive agent.

[0029] The aqueous solvent is double distilled water or alcohol / IPA with a concentration of 10%~80%. Since double distilled water or alcohol, IPA contains hydroxyl groups, it can be better compatible with the hydroxyl group...

Embodiment 3

[0032] The configuration of the aluminum foil pre-coated nano-conductive carbon oil-based primer, in mass percent.

[0033] Weigh 1000 grams of N-methylpyrrolidone NMP with a purity greater than 98% as an oily solvent, 35 grams of polyvinylidene fluoride PVDF as a binder B, and mechanically stir for 6 hours under high-speed stirring to obtain a uniform and stable bond After that, add 20 grams (total mass is 60 grams) of powder nano-conductive carbon composite conductive agent system every 30 minutes for three times, and then use ultrasonic ultrasonic dispersion for 2 hours, and finally add 300 grams of NMP to adjust the viscosity. And finally obtain the oily primer with a viscosity of 3000 cps. The nano conductive carbon composite conductive agent is formed by mixing 10 grams of nano conductive carbon and 5 grams of Supper P composite conductive agent.

[0034] The binder B is selected as polyvinylidene fluoride (PVDF), and its molecular weight is between 1 million and 1.1 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com