A Method for Electrochemically Strengthening Coal Gas Desorption Seepage

It is a technology of desorption and seepage flow and electrochemistry, which is applied in gas discharge, earthwork drilling, safety devices, etc., to prevent coal and gas outburst, prevent rock burst, and improve the effect of escaping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0019] The method for electrochemically strengthening coal gas desorption and seepage of the present invention performs electrochemical strengthening of coal gas desorption and seepage on a coal seam in a coal mining face, so as to improve the extraction rate of coal seam gas. The process is:

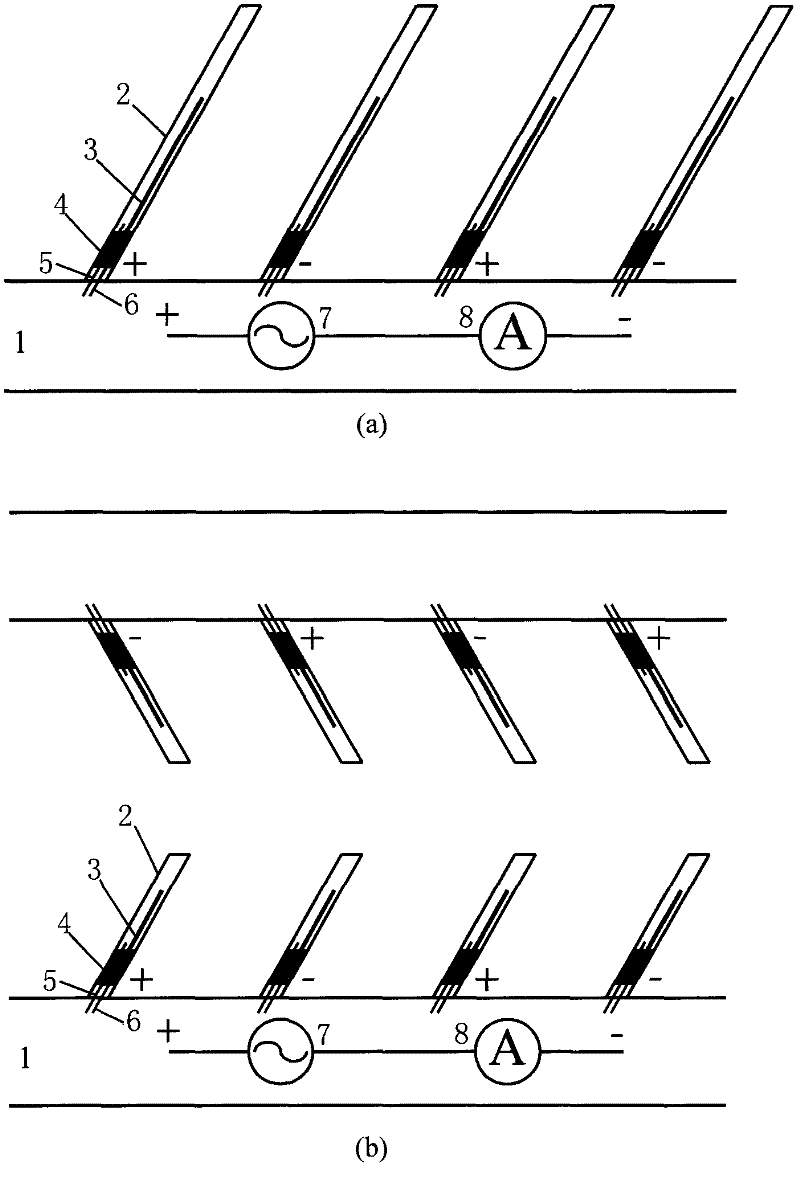

[0020] I. In a mine 3 # Drilling holes in coal seam roadways, according to figure 1 (a) The electrochemically strengthened coal gas desorption seepage system shown in (a) is electrochemically strengthened;

[0021] II. Electrodes are arranged on one side of the coal wall of the inclined roadway. The electrode material is Fe, and the electrode length is 2 / 3 of the drilling depth. The adjacent electrodes are connected with the positive and negative electrodes of the external electric field and the ammeter, and the holes are sealed and the electrolyte is injected;

[0022] III. The applied electric field is a DC electric field, and the electric field strength is 0.25V cm -1 ~6.6V·cm -1...

Embodiment approach 2

[0025] Implementation Mode 2: According to figure 1 (a) The electrochemically enhanced coal gas desorption seepage system shown in (a), the electrodes are arranged on one side of the vertical working face, and the electric field strength is 1V cm -1 , the electrolyte is water, and the coal seam gas recovery rate after electrochemical strengthening is increased by about 11%. Others are the same as Embodiment 1.

Embodiment approach 3

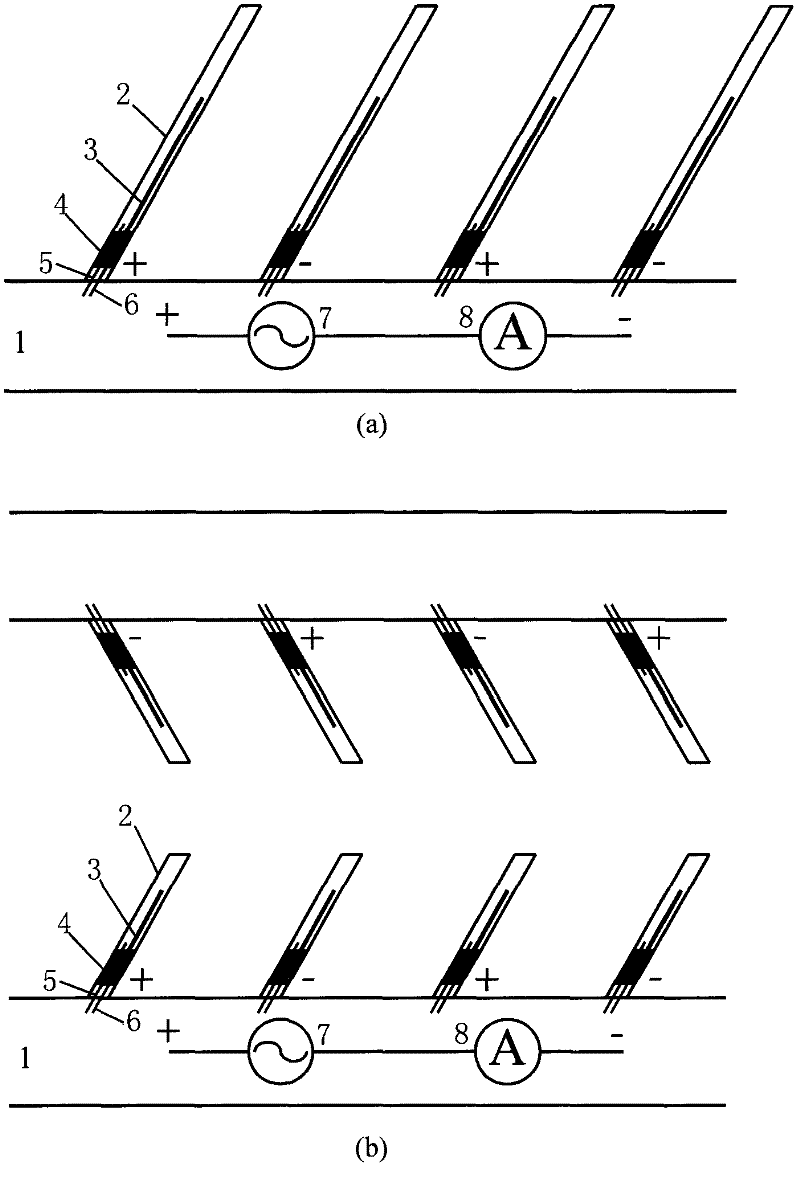

[0026] Implementation Mode 3: According to figure 1 (b) The electrochemically enhanced coal gas desorption seepage system shown in (b), the electrodes are arranged on both sides of the coal wall of the oblique roadway, and the electric field strength is 1V cm -1 , the electrolyte is KOH, the concentration is 0.5mol l -1 , the coal seam gas recovery rate increased by about 17% after electrochemical enhancement. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com