Standard constant temperature tank touch screen intelligent measurement and control and automatic measurement detection system

A detection system and automatic metering technology, applied in thermometers, measuring devices, measuring heat, etc., can solve the problems of inability to obtain stable temperature feedback information in time, low utilization rate and detection efficiency of thermostatic baths, and inability to automatically print certificates and records. , to achieve the effect of convenient program design and calling, improve operability, and reduce detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

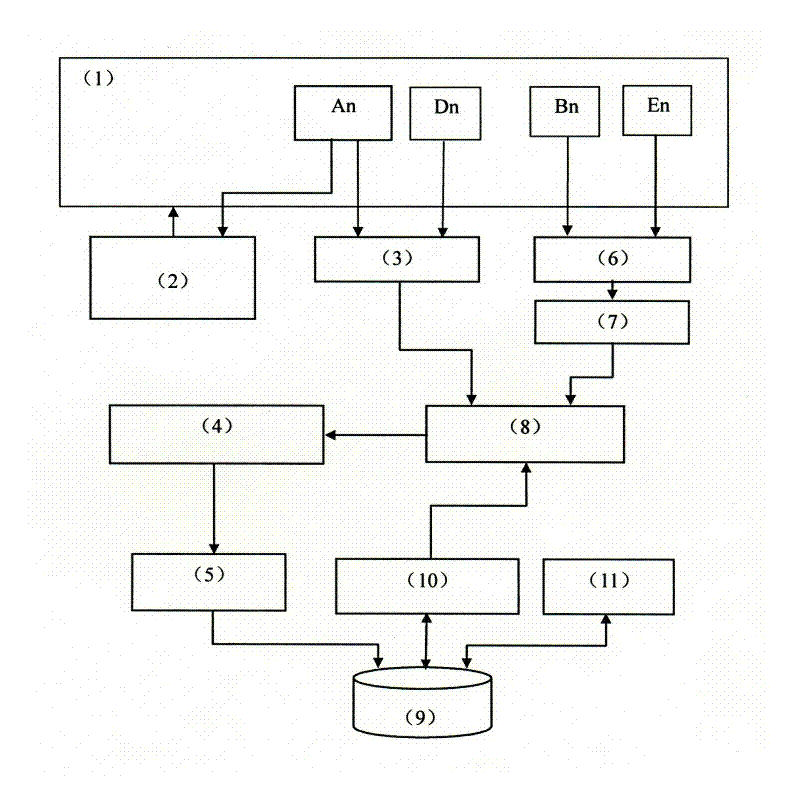

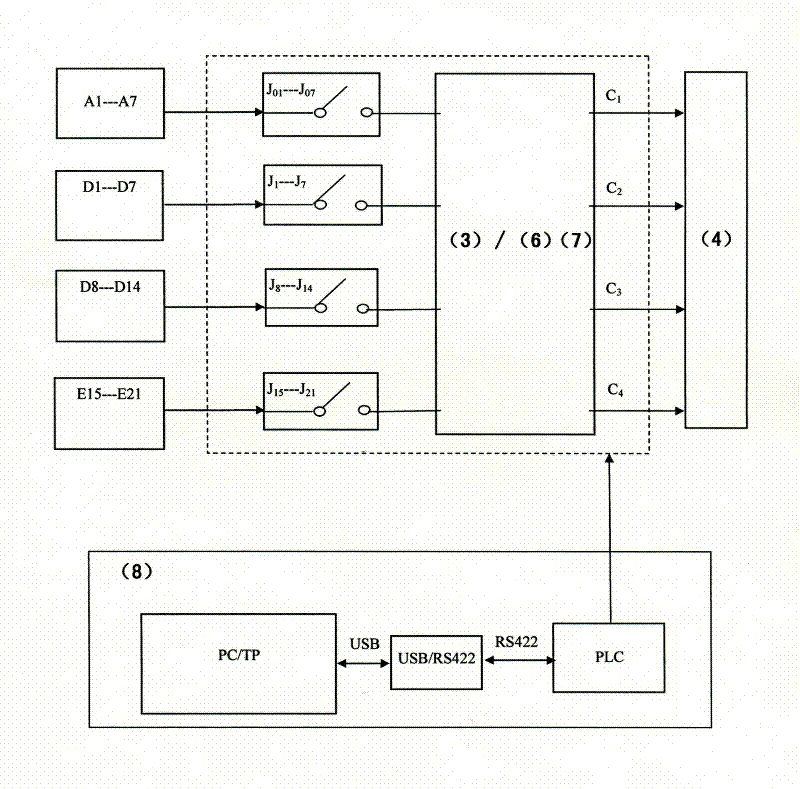

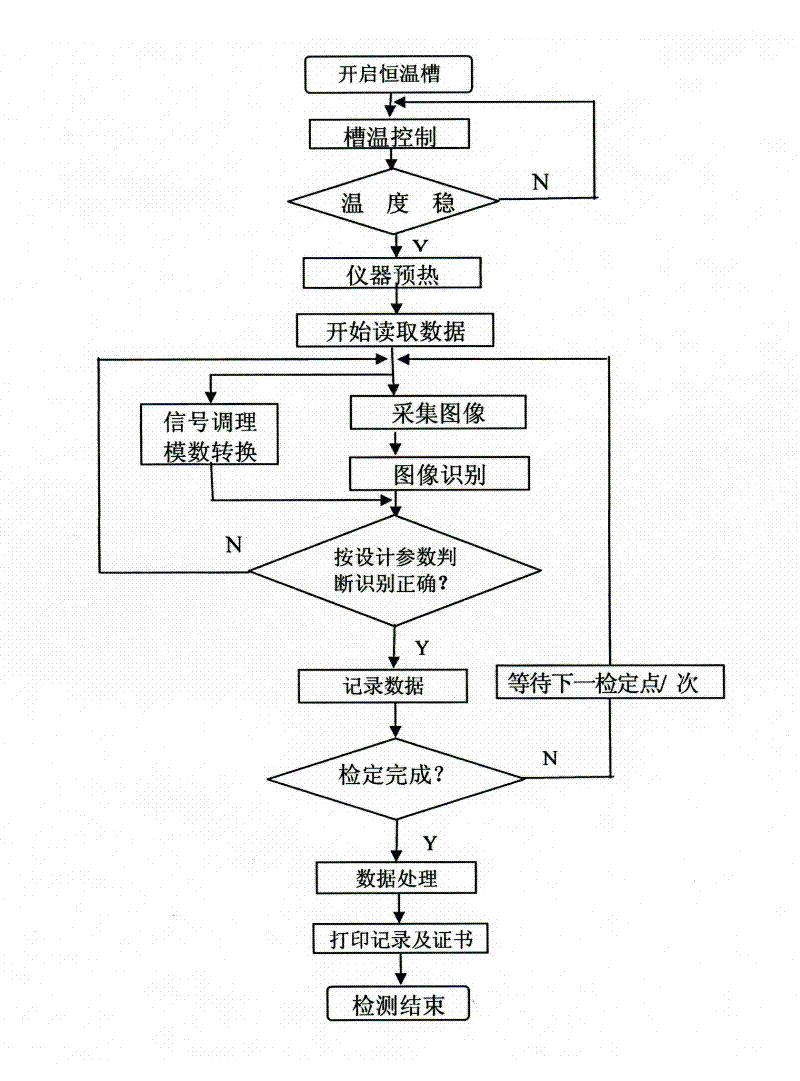

[0038] see Figure 1~3 As shown, a standard constant temperature tank touch screen intelligent measurement and control and automatic measurement detection system, which consists of a standard constant temperature tank 1, a touch screen and PLC intelligent temperature controller 2, multi-channel electrical signal acquisition conditioning and conversion equipment 3, temperature comparator / counter 4 , data processing and monitor 5, multi-channel image signal acquisition equipment 6, image recognition and controller 7, intelligent channel switching and controller 8, database management and storage 9, intelligent parameter control unit 10 and record query and certificate printing The device 11 is composed. The standard constant temperature bath 1 is provided with a working area and a control area, and a temperature instrument to be tested (E n ), the tested temperature sensor (D n ) and standard standard temperature gauge (B n ), standard temperature sensor (A n ), equipped wit...

Embodiment 2

[0044] see Figure 1~3 As shown, the verification process of the tested thermal resistance is verified by using the standard constant temperature tank touch screen intelligent measurement and control and automatic measurement detection system.

[0045] This embodiment adopts the second-class standard platinum resistance thermometer (A 1 ) to 7 B graduation Pt100 tested platinum thermal resistances (D 1 )—(D 7 ) for verification. According to the requirements of the verification regulations, the B-gradation platinum thermal resistance should be verified at two temperature points of 0°C and 100°C, and each point should be inspected twice.

[0046] Preparations before verification: The verification personnel put the tested and standard temperature instruments into the working area of the standard constant temperature bath 1, immerse them in a depth of not less than 300mm according to the verification regulations, and put the second-class standard platinum resistance thermome...

Embodiment 3

[0053] see Figure 1~3 As shown, the verification process of the thermocouple under test is verified by using the standard constant temperature tank touch screen intelligent measurement and control and automatic measurement and detection system.

[0054] This example uses a standard thermocouple (A 2 ) to 7 thermocouples to be tested with T indexing (D 8 )—(D 14 ) for verification. According to the requirements of the verification regulations, the three temperature points of 0°C, 50°C and 100°C should be verified by the T-gradient thermocouple, and each point should be inspected 4 times.

[0055] Preparations before verification: The verification personnel put the tested and standard temperature instruments into the working area of the standard constant temperature bath 1, immerse them in a depth of 200mm according to the verification regulations, and put the standard thermocouple (A 2 ) connection (C 1 ) One of the multi-point terminals of the detection channel (option...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com