Overvoltage protection element and manufacturing method thereof

A technology for protection components and manufacturing methods, applied in the direction of overvoltage protection resistors, resistance manufacturing, electrical components, etc., can solve problems such as high trigger voltage, reduced conductivity, poor conductivity, etc., to reduce trigger voltage and improve conductance generality, the effect of enhancing the protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

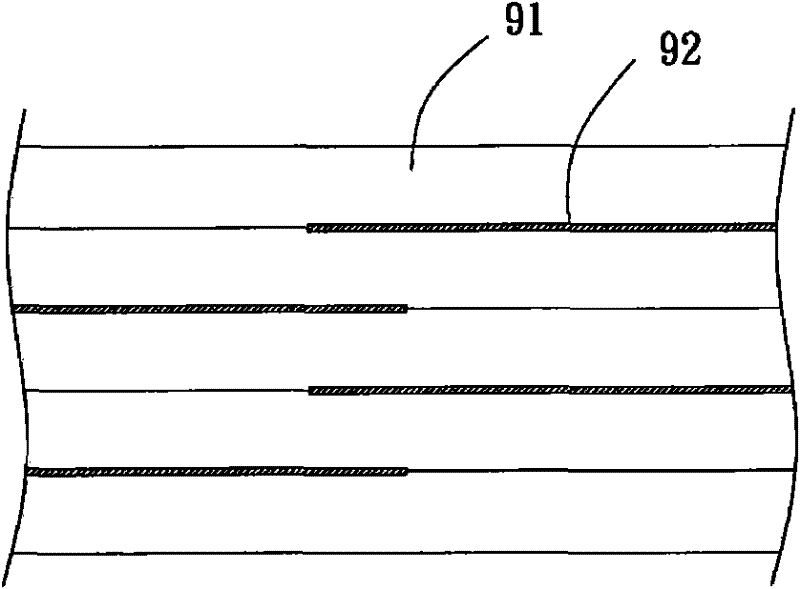

[0051] Please refer to Picture 10 As shown, the overvoltage protection element of the preferred embodiment of the present invention includes a substrate 1, two electrodes 2 and a driving layer 3.

[0052] The substrate 1 of the present invention can be selected as a glass substrate, a ceramic substrate or a substrate made of other materials.

[0053] The two electrodes 2 of the present invention are arranged on the surface of the substrate 1. The electrodes 2 are preferably made of materials with better conductivity, such as platinum (Pt), silver (Ag), or copper (Cu), etc. . A distance w is formed between the two electrodes 2, and the distance w can be adjusted according to the trigger voltage required by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com