Fabrication method of coupled waveguide laser with integrated photonic crystal phase modulator

A technology of phase modulator and coupling waveguide, which is applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., to achieve high quality and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

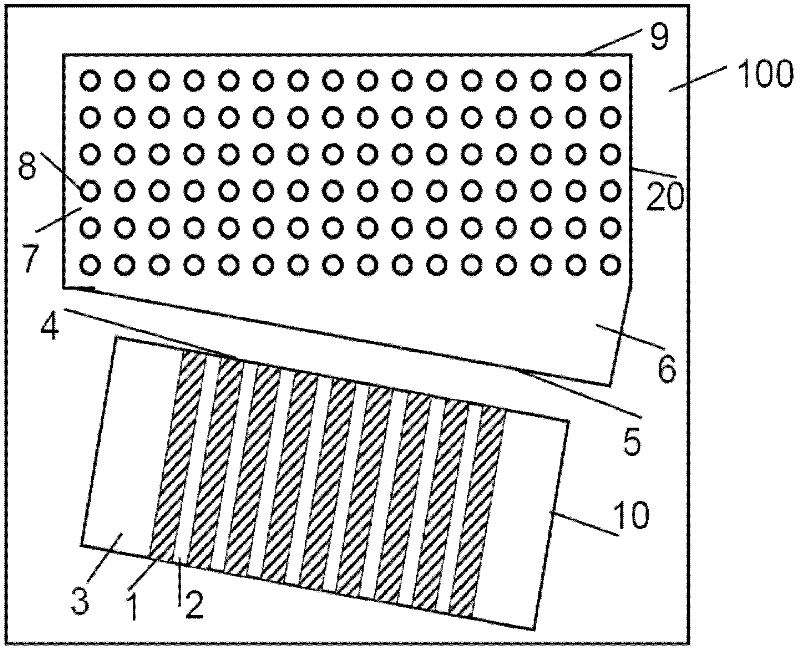

[0027] see figure 1 , figure 2 Shown, the preparation method of the coupled waveguide laser of a kind of integrated photonic crystal phase modulator provided by the present invention, wherein each unit comprises the following steps:

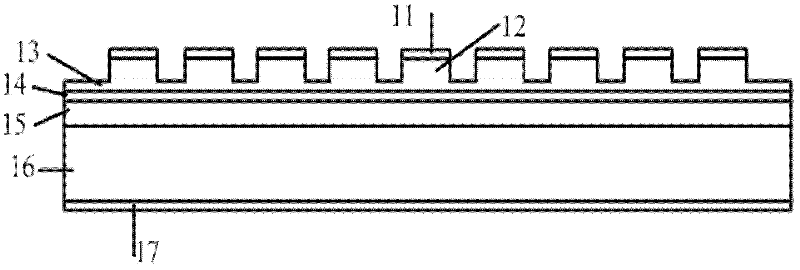

[0028] Step 1: Take an active gallium arsenide epitaxial wafer 100, the active gallium arsenide epitaxial wafer 100 includes a substrate 16, a lower confinement layer 15, an active layer 14 and an upper confinement layer 13;

[0029] Step 2: Etching the periodic coupling waveguide structure 10 on the upper confinement layer 13 of the active gallium arsenide epitaxial wafer 100; 3 do not inject;

[0030] Step 3: Prepare metal electrodes 11 and 17 respectively on the surface of the periodically coupled waveguide structure 10 and under the substrate 16;

[0031] Step 4: Prepare a photonic crystal phase modulator 20 on one side of the coupling waveguide structure 10, and the distance between the coupling waveguide structure 10 and the photonic cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com