Lead sheet cold granulator

A technology of cold granulator and lead flakes, which is applied in the field of cutting soft metals in a cold state. It can solve the problems of lead poisoning that damages human health and consumes energy, and achieves the effects of improving the production environment, reducing pollution, and achieving the effect of detachment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

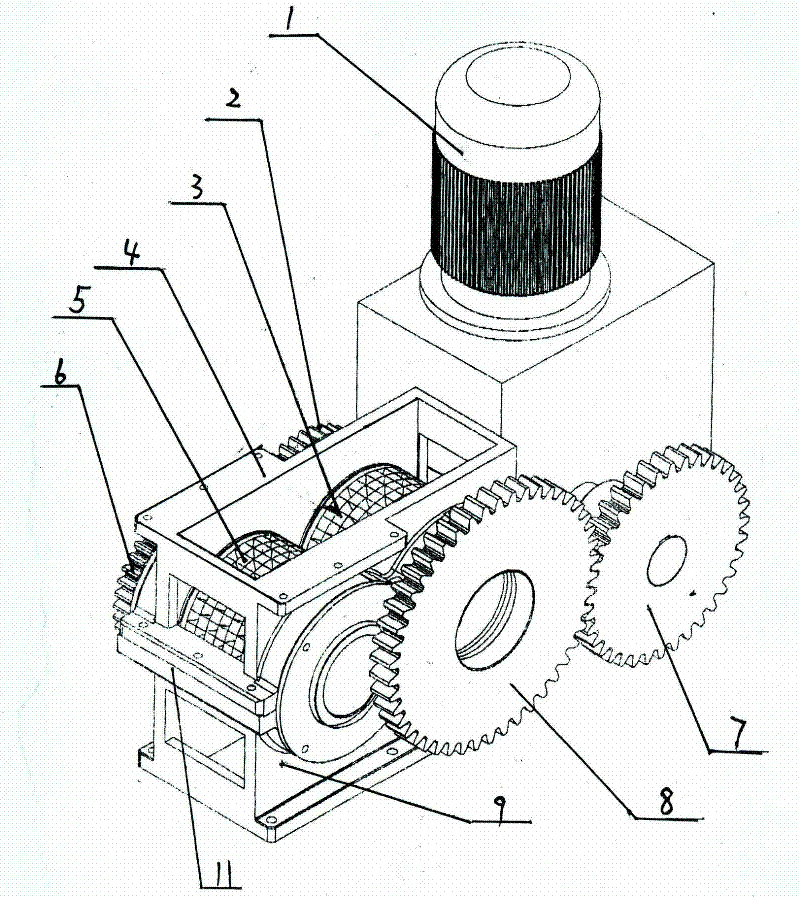

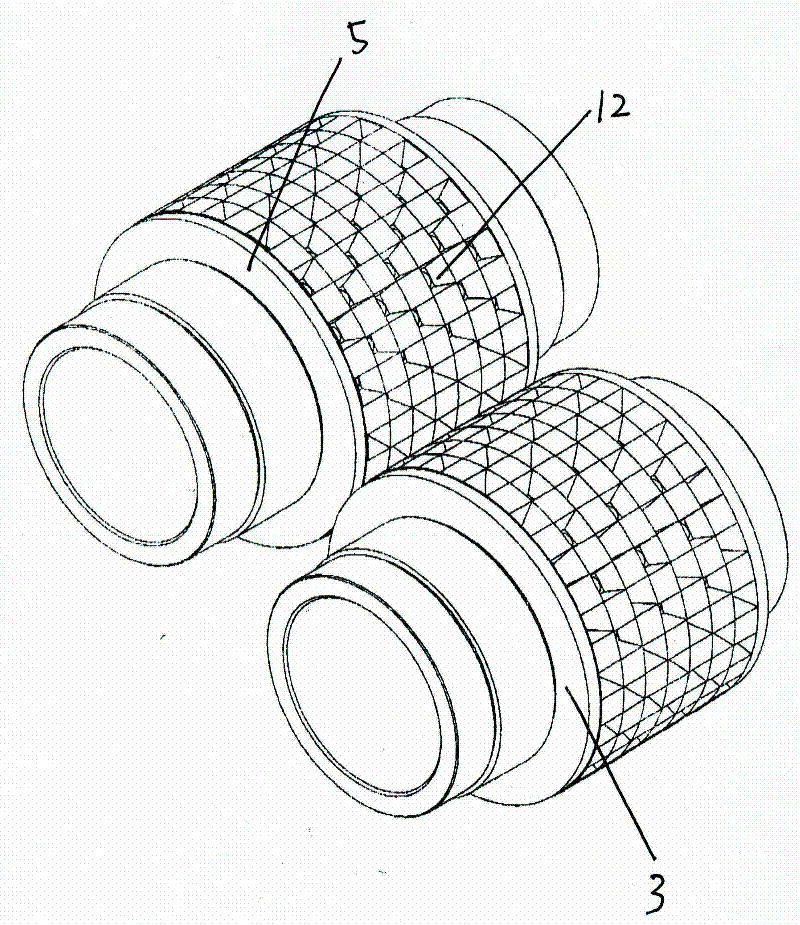

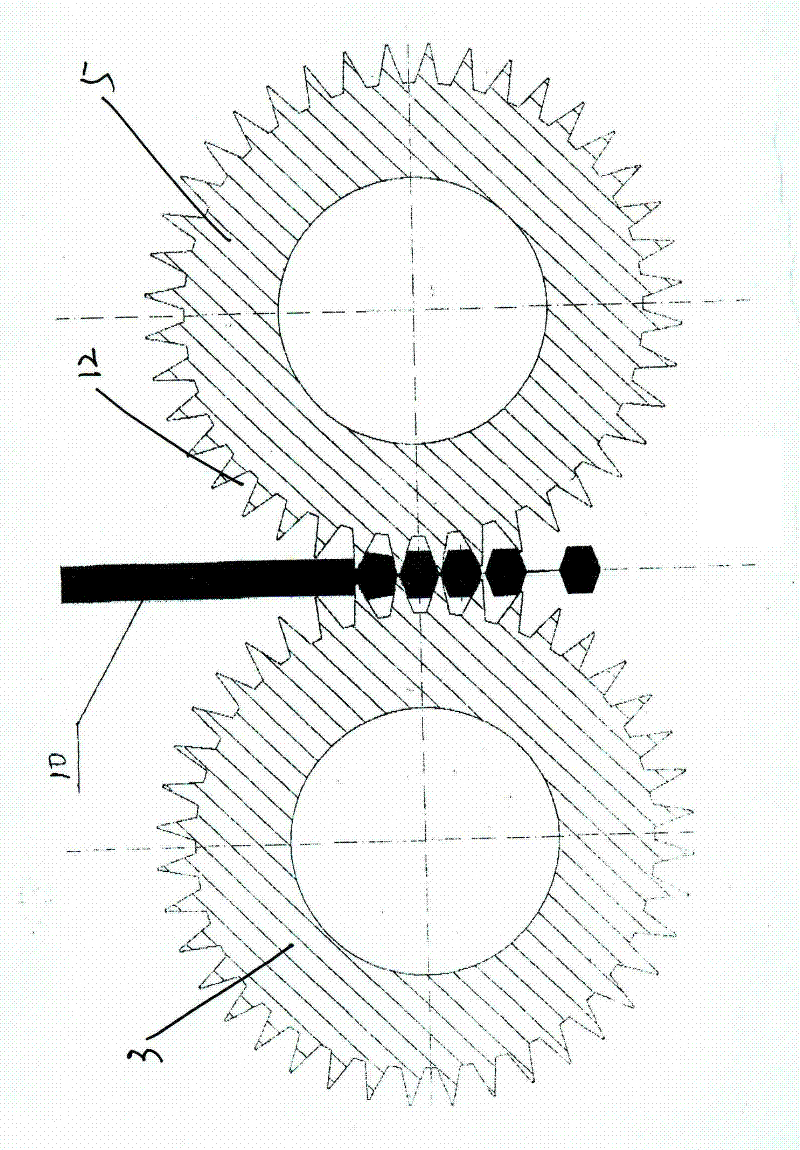

[0018] Referring to the accompanying drawings, the lead sheet cold granulator includes a frame 11, the frame is provided with a casing, the casing is divided into an upper casing 4 and a lower casing 9, and the upper end of the frame is equipped with a motor 1, a motor 1 There is an active transmission gear 7 under the rotating shaft, the active transmission gear 7 is meshed with the passive cutting gear 8 for transmission, and the active cutting roller 3 and the passive cutting roller 5 rotating in the opposite direction synchronously are installed in the casing, and one end of the active cutting roller is connected to the Active transmission gear 7 is fixedly installed, and the other end is fixedly installed with synchronous driving gear 2, and the end of passive cutting roller is fixedly installed with the synchronous passive gear 6 that is meshed with the synchronous driving gear, and the outer walls of active cutting roller and passive cutting roller are distributed with G...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap