Welding wire for X80 steel low-temperature resistant steel pipe and pipe fittings

A technology of low temperature resistance, steel pipe, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of low temperature resistance and toughness decrease, and achieve the effect of high and low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The chemical composition and content (percentage by weight) of the welding wire in this embodiment are shown in Table 1. According to the chemical composition shown in Table 1, the metal wire rod is cold-drawn and sized to form an automatic welding wire with a diameter of φ4.0mm.

[0014] Table 1 Chemical composition list of welding wire

[0015] C Si mn P S Ni 0.07% 0.10% 0.9% 0.012% 0.008% 3.6% Cr V Mo Ti B Fe 0.02% 0.005% 0 0.008% 0.0008% margin

[0016] Use the welding wire of this embodiment to weld the steel pipe with a diameter of φ1016×22, the welding current is 450-550A, the arc voltage is 28-32V, and the weld performance after welding is tested. The test results are shown in Table 2.

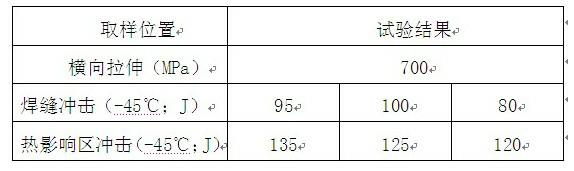

[0017] Table 2 Performance test results

[0018]

Embodiment 2

[0020] The chemical composition and content (percentage by weight) of the welding wire in this embodiment are shown in Table 3. According to the chemical composition shown in Table 3, the metal wire rod is cold-drawn and sized to form an automatic welding wire with a diameter of φ3.2mm.

[0021]

[0022] Table 3 Chemical Composition of Welding Wire

[0023] C Si mn P S Ni 0.09% 0.15% 1.2% 0.009% 0.006% 2.5% Cr V Mo Ti B Fe 0 0.005% 0.10% 0.01% 0.0004% margin

[0024] Use the welding wire of this embodiment to weld the steel pipe with a diameter of φ1016×22. The welding current is 450-550A and the arc voltage is 28-32V. The performance of the weld seam after welding is tested. The test results are shown in Table 4.

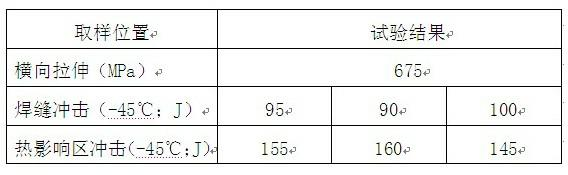

[0025] Table 4 Performance test results

[0026]

Embodiment 3

[0028] The chemical composition and content (percentage by weight) of the welding wire in this embodiment are shown in Table 5. According to the chemical composition shown in Table 5, the metal wire rod is cold-drawn and sized to form an automatic welding wire with a diameter of φ4.2mm.

[0029] Table 5 Chemical Composition of Welding Wire

[0030] C Si mn P S Ni 0.08% 0.20% 1.5% 0.016% 0.006% 2.8% Cr V Mo Ti B Fe 0.10% 0.01% 0.20% 0 0.001% margin

[0031] Use the welding wire of this embodiment to weld the steel pipe with a diameter of φ1016×22, the welding current is 450-550A, the arc voltage is 28-32V, and the performance of the weld seam after welding is tested. The test results are shown in Table 6.

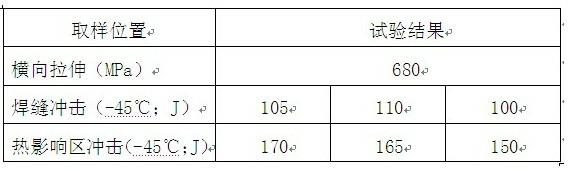

[0032] Table 6 Performance test results

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com