Preparation method of carboxymethyl levan and applications thereof

A technology for carboxymethyl levan and levan, which is applied in the field of preparation of carboxymethyl levan, can solve the problems of low degree of substitution of carboxymethyl inulin, inhibiting scale inhibition effect and the like, and achieves the inhibition of calcium salts. the deposition of calcium salts, or to prevent the deposition of calcium salts, the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

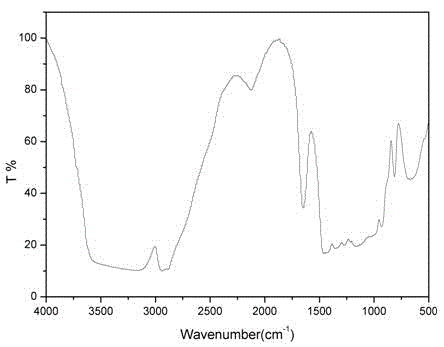

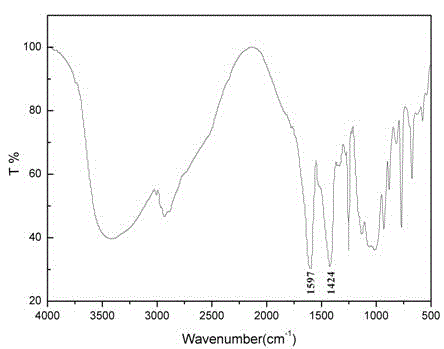

Image

Examples

Embodiment 1

[0028] Preparation of carboxymethyl levan: first weigh 3.24g levan, add 50ml of isopropanol to a reaction vessel (such as a three-neck flask), fix the flask under the stirrer, and add levan while stirring slowly. Then transfer the flask to a water bath, control the temperature of the water bath to 35°C, add 2g of solid sodium hydroxide to the mixture in batches, and stir for 30min; weigh 1.89g of monochloroacetic acid solid, put it into a 25ml beaker, and add 10ml With isopropanol, stir until monochloroacetic acid is completely dissolved, then adjust the reaction temperature to 50°C, add monochloroacetic acid isopropanol solution while stirring, and wait until the monochloroacetic acid solution is added gradually, then stir and react in a water bath at constant temperature for 3 hours. After the reaction, the reaction product was poured into a beaker, allowed to stand for precipitation, then poured off the supernatant, and the precipitation was washed 4 times with alcohol solut...

Embodiment 2

[0032] The difference from Example 1 is: take 3.24g of levan, add 60ml isopropanol in a three-necked flask, fix the flask under the stirrer, add levan while stirring slowly, then transfer the flask to a water bath In the pot, control the temperature of the water bath to 35°C, add 3.2g solid sodium hydroxide to the mixture in batches, and stir for 60 minutes; weigh 3.78g solid monochloroacetic acid, put it into a 50ml beaker, add 30ml isopropanol, and stir Until the monochloroacetic acid is completely dissolved, keep the reaction temperature at 35°C, and gradually add the monochloroacetic acid isopropanol solution while stirring. After the monochloroacetic acid solution is gradually added, stir and react in a water bath at constant temperature for 5 hours. After the reaction, pour the reaction product into a beaker, let it stand for precipitation, pour off the supernatant, and wash the precipitation 5 times with alcohol solution. The product was dried in an oven at 70°C for 3 h...

Embodiment 3

[0035] The difference from Example 1 is: take 3.24g of levan, add 50.5ml isopropanol solution in the three-necked flask, fix the flask under the stirrer, add levan while stirring slowly, then transfer the flask Put into a water bath, add 0.8g of sodium hydroxide solid to the mixed solution in batches at room temperature, and stir for 15 minutes; weigh 0.945g of monochloroacetic acid solid, put it into a 25ml beaker, add 9.5ml of isopropanol, and stir until The monochloroacetic acid was completely dissolved, and then the reaction temperature was adjusted to 80°C, and the isopropanol solution of monochloroacetic acid was gradually added while stirring. After the progressive addition of the monochloroacetic acid solution was completed, the reaction was stirred and reacted in a water bath at constant temperature for 1 hour. After the reaction, pour the reaction product into a beaker, let it stand for precipitation, pour off the supernatant, and wash the precipitation with alcohol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com