Oligomerisation of olefinic compounds in the presence of an activated oligomerisation catalyst

一种烯属化合物、催化剂的技术,应用在提供活化的低聚催化剂领域,能够解决未示例性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

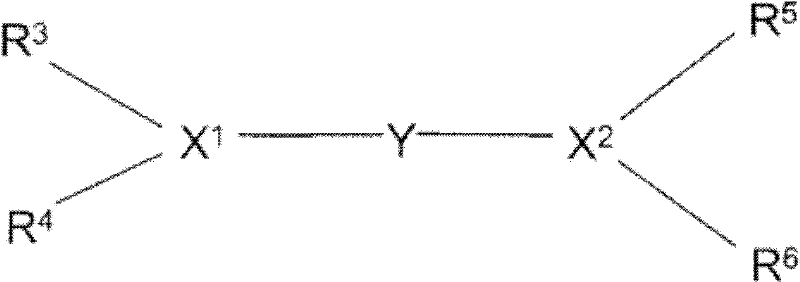

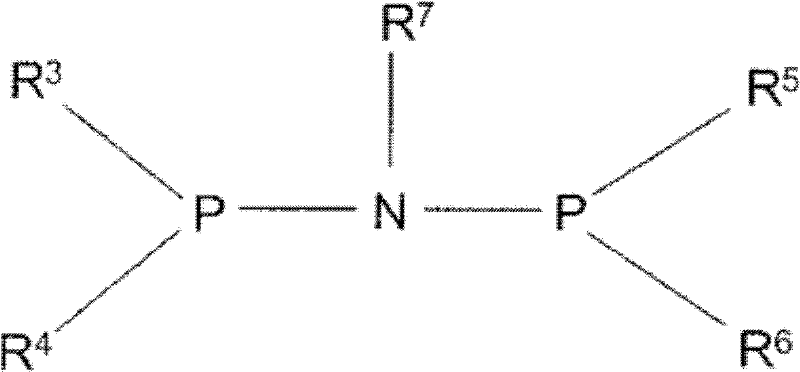

Method used

Image

Examples

Embodiment Construction

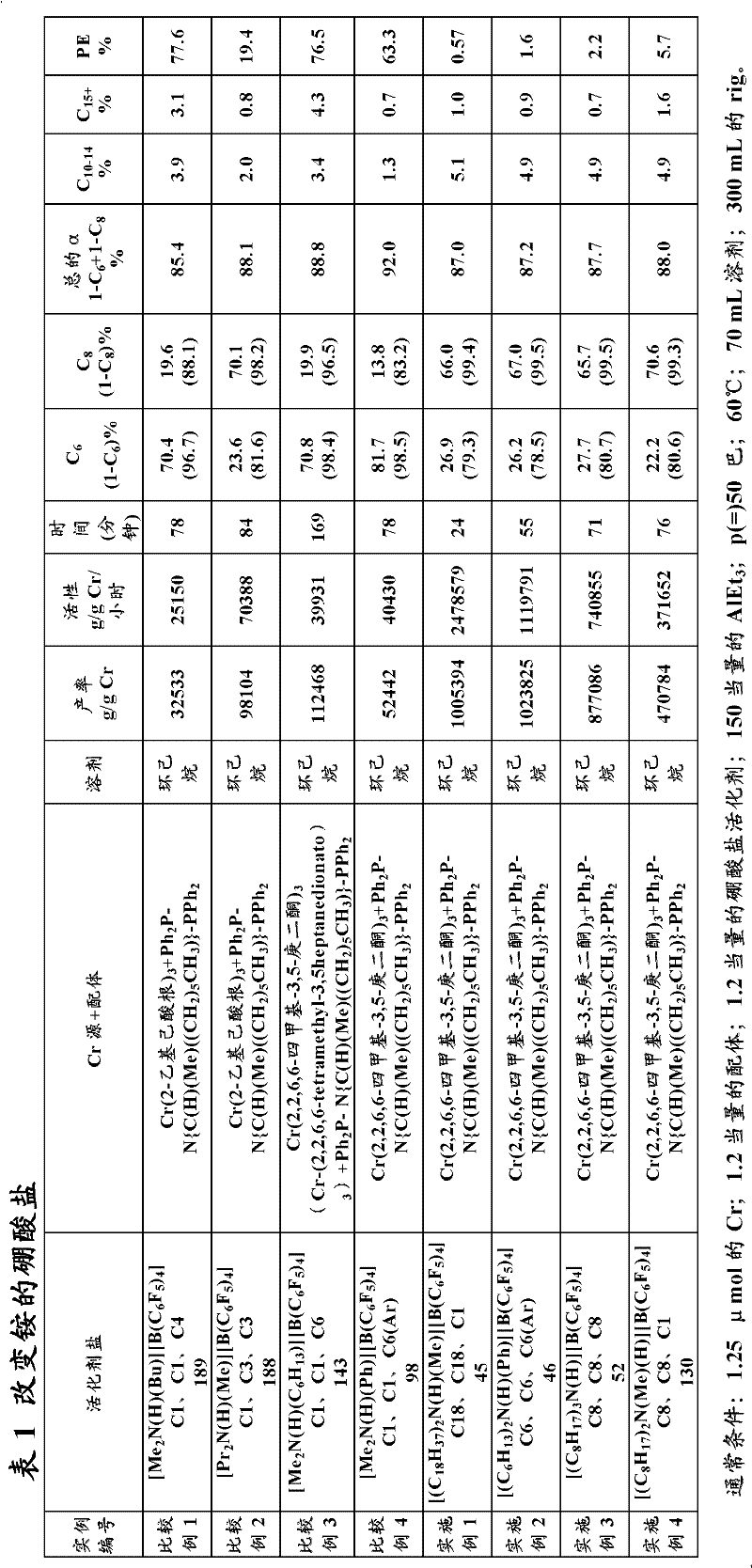

[0245] Ordinary catalysis was performed in a 300 mL volume High Pressure Engineered Reactor equipped with a stainless steel vessel with a removable thermofluid jacket or in a 1.2 L Premex autoclave with a stainless steel vessel with an integral thermofluid jacket. Both reactors were equipped with mechanical gas entrainment stirring and internal cooling coils. Ethylene (grade 4.5) was supplied by Linde and passed through a scrubber before use; the flow of ethylene was measured and recorded using a Siemens Sitrans FC Massflo system (Mass 6000-Mass 2100). GC analysis was performed using an Agilent Technologies 6850Network GC system equipped with a PONA column (50 m x 0.20 mm x 0.50 μm) and using hydrogen as a carrier gas. All catalytic tests were run until ethylene uptake ceased either because the catalyst was deactivated or because the autoclave had filled up.

[0246] Prepare mixed chromium (1.25 μmol / mL) / ligand (1.5 μmol / mL) stock solutions in relevant solvents. Dilute the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com