Production method of evaporated vegetables

A production method and technology of dehydrated vegetables, applied in the direction of preserving fruits/vegetables through dehydration, can solve the problems of insufficient research on functional dehydrated vegetables, and achieve the effects of rehydration, compensation of shrinkage, and reduction of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

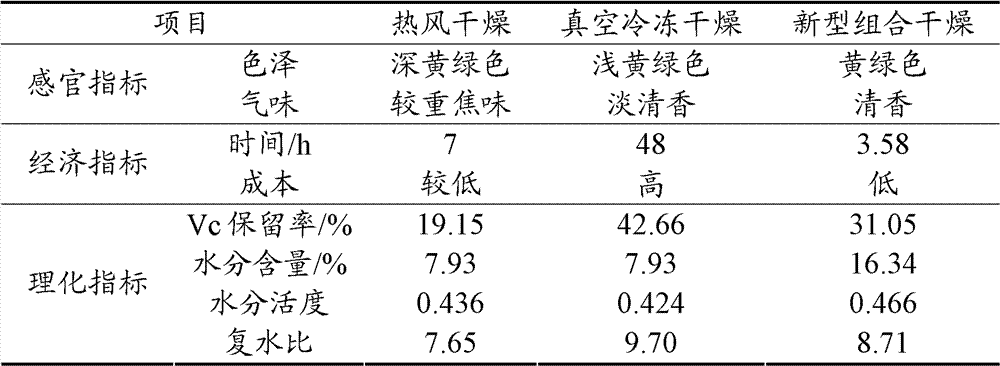

Image

Examples

Embodiment 1

[0083] Example 1 : the production of dehydrated eggplant of the present invention

[0084] Select 2500g of fresh long-shaped eggplant (moisture content is about 80%), remove the head and tail, wash, cut into slices with a thickness of 20mm, blanch with boiling water for 3 minutes, cool quickly with tap water, spread it evenly on a drying plate, put Put it into an oven produced by Shanghai Boxun Industrial Co., Ltd., dry it at a temperature of 70°C for 3.5 hours, and measure its moisture content according to the national standard GB 8858-88 "Methods for Determination of Dry Matter and Moisture Content in Fruit and Vegetable Products". Said eggplant gross weight is 62%. Take it out of the oven and put it in a microwave oven produced by Guangzhou Microwave Heating and Drying Equipment Co., Ltd., at 3.0W.g -1 Under the condition of dry 15min, it is measured that its water content is 39% on the basis of described eggplant gross weight, obtains dry eggplant 800 grams. At normal t...

Embodiment 2

[0086] Example 2 : the production of dehydrated carrot of the present invention

[0087] Implement in the same manner as in Example 1, but select 1000g of fresh carrots, cut into slices with a thickness of 20mm, scald them in boiling water for 5 minutes, dry them at a temperature of 70°C for 2.5h, measure their moisture content as described The total weight of carrots is 61%. Then microwave drying, at 2.5W.g -1 Under the condition of dry 15min, it is measured that its water content is 36% on the basis of described carrot gross weight, obtains dry carrot 250 grams. At normal temperature, all the dried carrots were immersed in 90 mL of permeate containing 28% mannitol and 15% salt, stirred evenly, left for 30 minutes, and then put back into the oven. Drying was continued at a temperature of 70° C. for 1.2 hours to obtain 235 g of dehydrated carrots.

[0088] At a temperature of 25°C, measured by the method described in this specification, the water content of the dehydrated...

Embodiment 3

[0089] Example 3 : the production of dehydrated sponge gourd of the present invention

[0090] Carry out in the same manner as in Example 1, but select 2000g of fresh loofah, wash, cut into slices with a thickness of 20mm, scald in boiling water for 2 minutes, put into a hot air drying oven, and dry at a temperature of 65°C 2h, measure that its water content is 60% on the basis of the total weight of the sponge gourd. Then microwave drying, at 2.5W.g -1 Dry 15min under the condition of above-mentioned condition, measure that its water content is 38% on the basis of described sponge gourd gross weight, obtains dry sponge gourd 490 grams. At room temperature, let the dried loofah be completely immersed in 165mL of permeate containing 25% sorbitol and 15% salt, stir evenly, place for 15min, and then put it back into the oven. Drying was continued for 0.8 hours at a temperature of 65° C. to obtain 430 g of dehydrated loofah.

[0091] At a temperature of 25°C, measured by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com