Leakage detection method and leakage detection device of large soft transfusion package bags or soft bottles

A technology of flexible packaging bags and large infusions, applied in the direction of measuring the acceleration and deceleration rate of fluids, using liquid/vacuum degree for liquid tightness measurement, sorting, etc. and other problems, to achieve the effect of reducing intensity and contingency, ensuring effect and quality, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

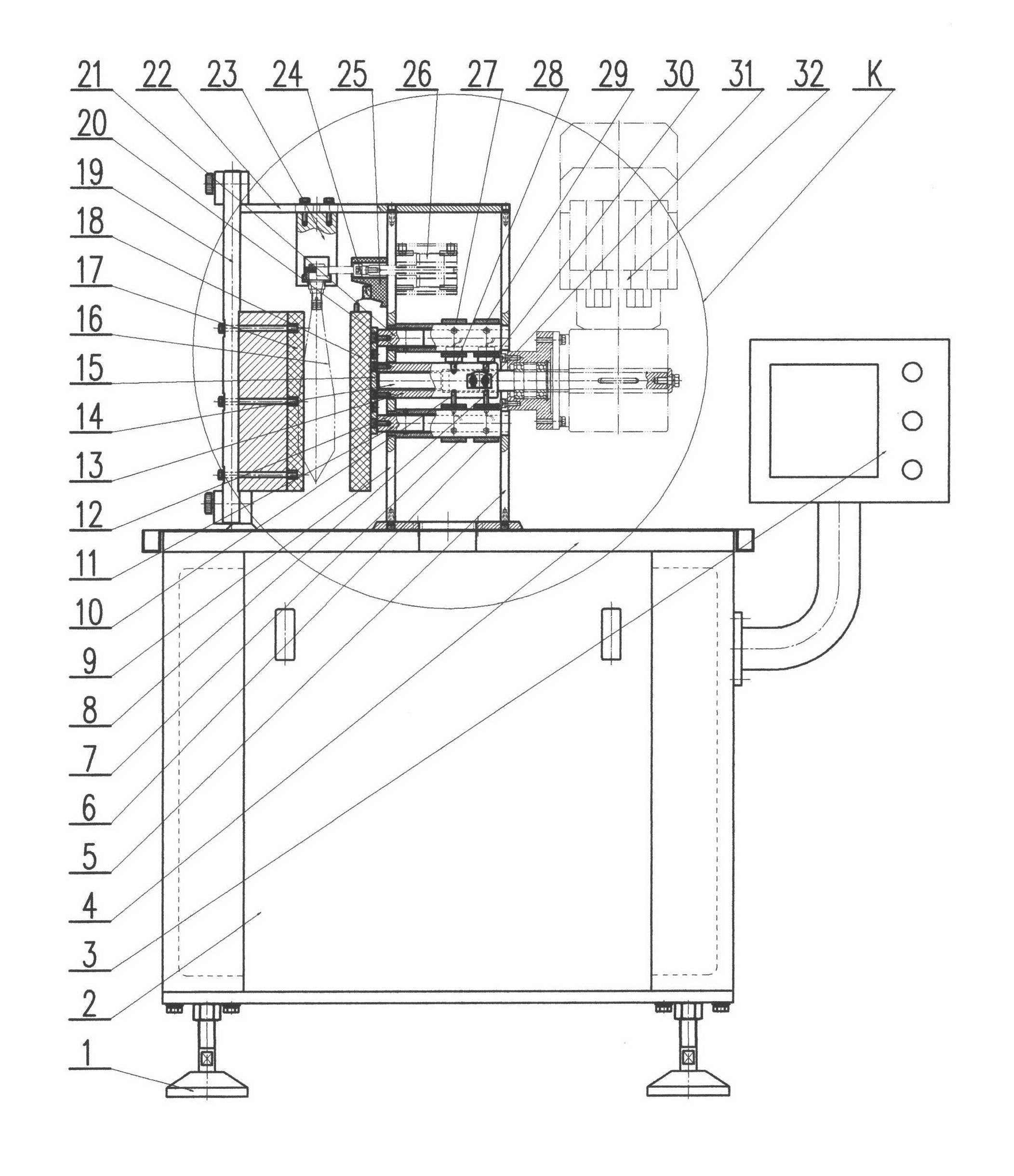

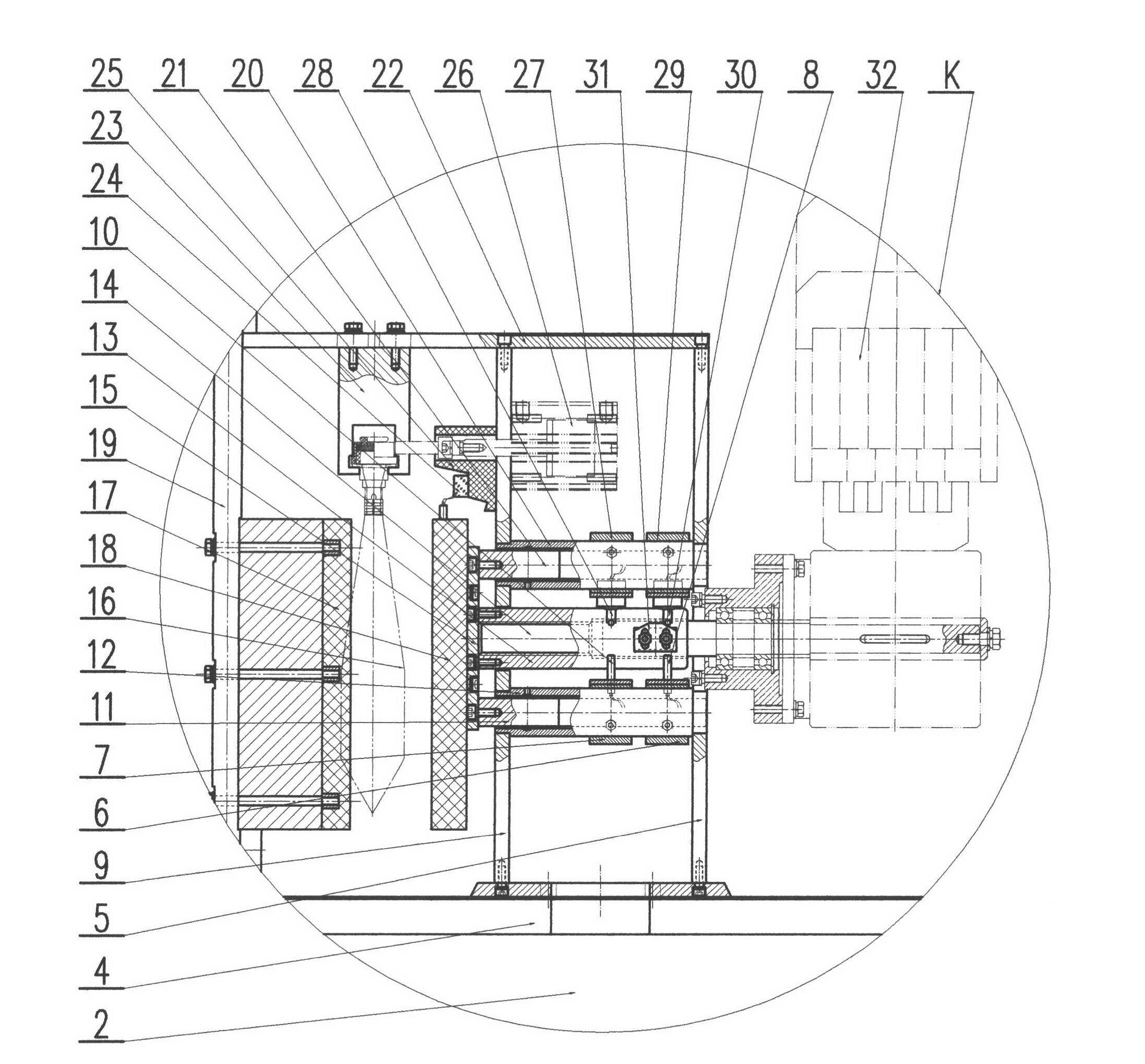

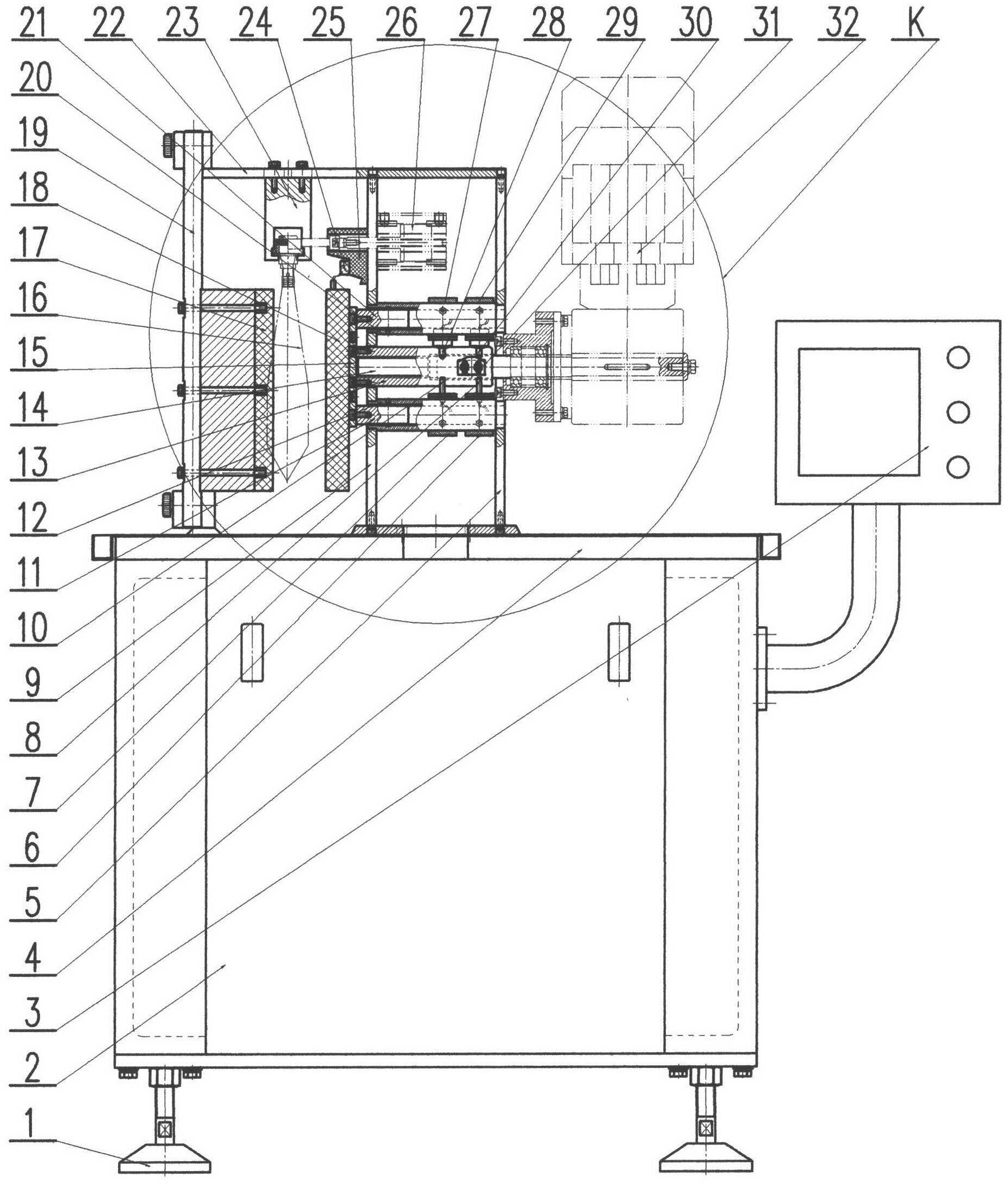

[0044] Present embodiment is made of frame 4, program logic controller 3, vertical beam 19, crossbeam 22, extruding fixed plate 17, clamp 23, recycle bucket 2, motor 32 and leak detection parts with brake and deceleration parts.

[0045] The following device of frame 4 has four (also can be six or eight or more) frame feet 1, and its bottom device recycle bin 2, right side device program logic controller 3; The vertical beam 19 is installed on the left side, and the extruding fixed plate 17 is installed in the middle and lower part of the vertical beam 19; The top of the beam 19 and the top device crossbeam 22 of the leak detection part, the device clamp 23 below the crossbeam 22 between the two, see the attached figure 1 shown.

[0046] PLC electronic parts and voice prompt parts are housed in the program logic controller 3, and a leak detection switch is also housed on the panel.

[0047] The leak detection part is made of pressure sensor 18, pressure sensor mounting plate...

Embodiment 2

[0054] This embodiment is a technical solution improved on the basis of Embodiment 1. It is basically the same as Embodiment 1. The difference is that a rejecting device 26 is installed on the upper part of the left mounting plate 9 in the leak detection component. Device 26 is controlled by program logic controller 3, and during action, the operating rod that it protrudes passes after left mounting plate 9, can stretch in the clamp 23.

[0055] During use, when the detected pressure value change value exceeds the preset reference pressure value change range, it is determined that there is leakage in the large transfusion flexible packaging bag or soft bottle 16 to be leak-tested. At this time, the program logic controller 3 Send out unqualified prompt signal, output rejecting command at the same time, drive rejecting device 26, the action lever that rejecting device 26 protrudes will be installed on the fixture 23 and be installed on the large transfusion flexible packaging ba...

Embodiment 3

[0058] This embodiment is a technical solution improved on the basis of Embodiment 2, which is basically the same as Embodiment 2, with the difference that: on the upper part of the left mounting plate 9 in the leak detection component, there is also a detection sensor mounting seat 25, the presence sensor 24 is installed thereon.

[0059] During use, when the leak detection switch is started, the detection presence sensor 24 starts to detect immediately; when the detection presence sensor 24 detects that the large infusion solution soft packaging bag or soft bottle 16 to be leaked exists, the presence signal is sent to the program logic controller 3. The program logic controller 3 outputs instructions to start the motor 32 for detection; when the presence detection sensor 24 detects that the large transfusion flexible packaging bag or soft bottle 16 to be leak-tested does not exist, the absence signal is sent to the program logic control Device 3 sends the large infusion solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com