Method and equipment for low-temperature short-time deodorization of plant oil

A low-temperature short-time, vegetable oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of long deodorization time (2-3h, high deodorization temperature, etc., to reduce the amount of trans fatty acid produced, improve quality and quality, The effect of reducing the amount of excipients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

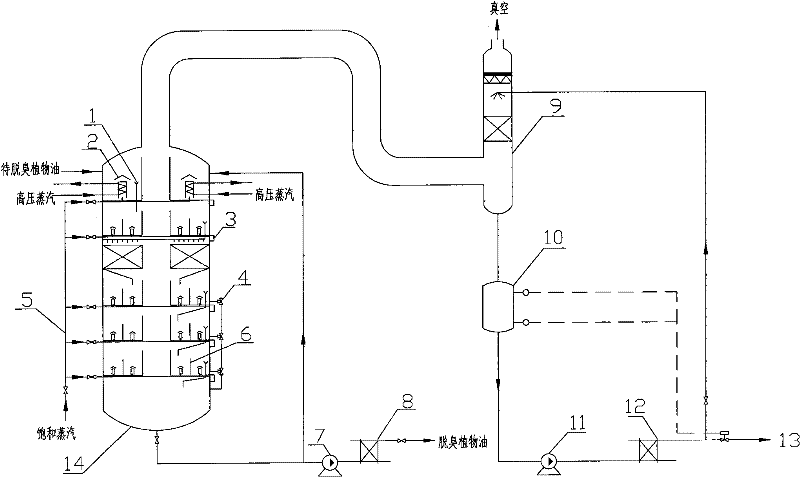

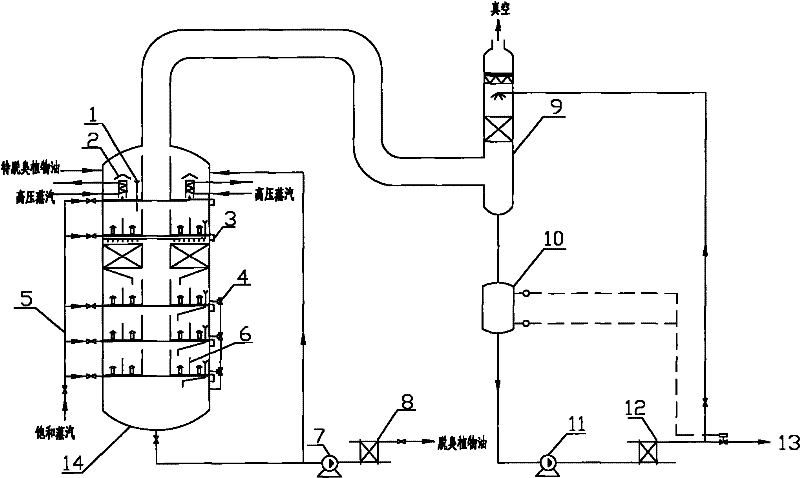

[0025] Such as figure 1 As shown, the present invention mainly uses a deodorization tower with a tower body structure of plate tower-packed tower-plate tower as the main deodorization equipment, which is a deodorization tower with adjustable deodorization time.

[0026] The deodorization equipment of the present invention includes a deodorization tower 14, the tower body structure of which is a tray tower on the first and second floors, a packed tower on the third floor, and a tray tower on the fourth floor. It may further include a fifth-story tray column and a sixth-story tray column. Three-way valves 4 are arranged outside the fourth, fifth and sixth-layer tray towers of the deodorization tower 14 and connected to each other. Each tray of the deodorization tower 14 is provided with an overflow pipe 1 , a mammoth pump 2 , an emptying pipe 3 and a baffle 6 . The pipe diameter of the emptying pipe 3 and the overflow pipe 1 are DN80, and the diameter of the three-way valve pi...

Embodiment 2

[0033] The deodorizing equipment used is the same as in Example 1.

[0034] The decolorized rapeseed oil is deoxidized by degasser at 130°C, heated to 170°C by heat exchanger, enters the plate tower, and heated to 212°C under the condition of vacuum degree of 3.9 Torr, directly steam stripped for 15min, and heat Sensitive decolorization, then enter the packed tower at 212°C, stay for 5 minutes, then enter the plate tower, directly steam strip for 15 minutes, cool the oil to 45°C through a heat exchanger, and then perform fine filtration to obtain deodorized oil.

[0035] Detect the deodorized oil index, the results are as follows, trans fatty acid content: 0.33%, vitamin E deodorization loss rate: 4.8%, sterol deodorization loss rate: 7.6%, free fatty acid content in deodorized oil is 0.032%, color: Y10R0.8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com