Method for culturing chlorella

A technology of chlorella and culture medium, which is applied in the field of microalgae biology, can solve problems such as the lack of corresponding improvement in oil accumulation efficiency, raw material limitations, and increased cultivation costs, so as to achieve high-quality and high-density culture of microalgae and solve pollution problems , The effect of cultivating high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The starting algae species is a kind of autotrophic microalgae isolated from nature, which is identified as Chlorella vulgaris after separation and purification in the laboratory. The laboratory number is FY1#. The medium used is the basic medium.

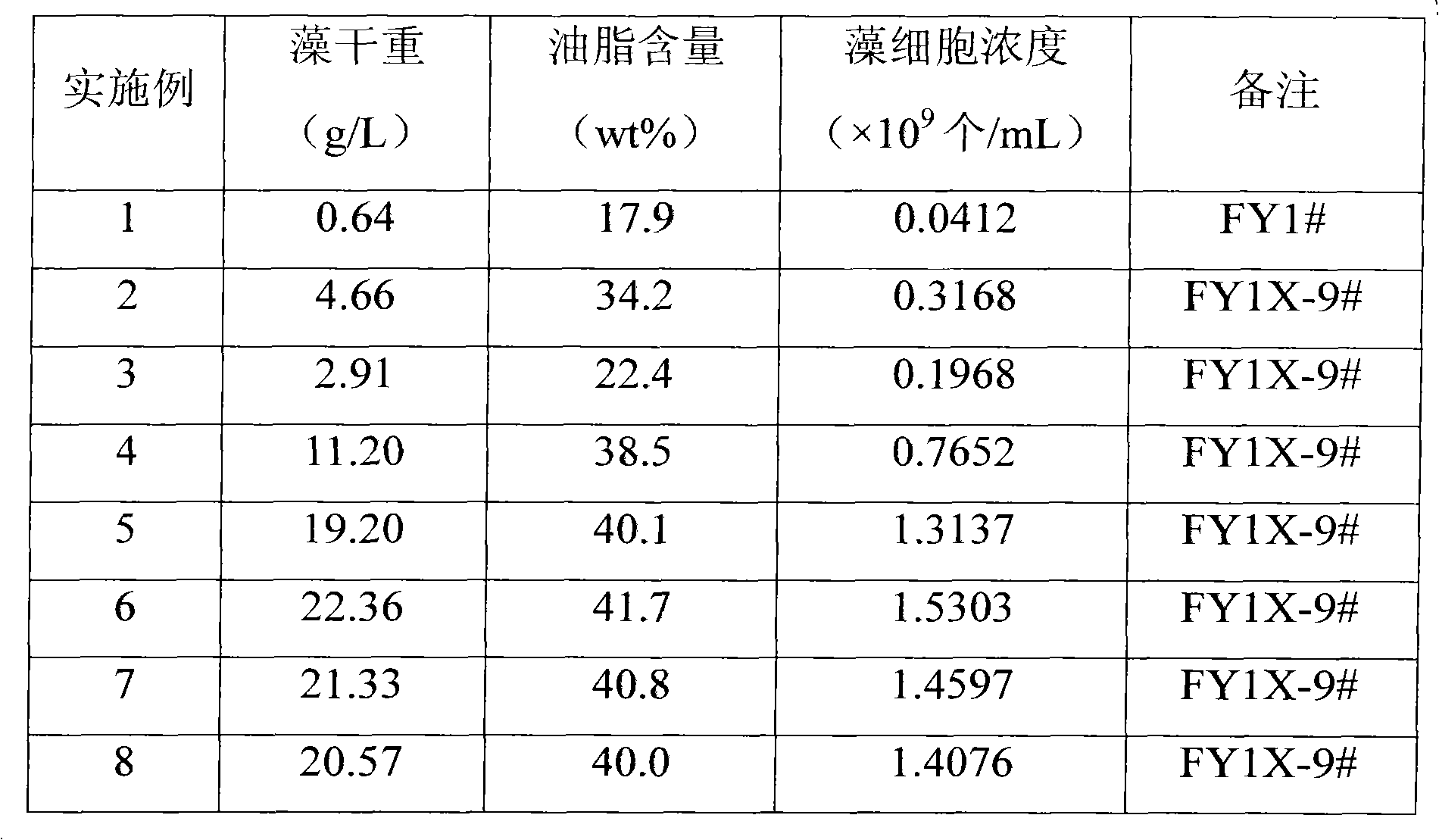

[0034] Table 1

[0035] NaNO 3

[0036] The chlorella species were transferred from the inclined plane to the shake flask and cultivated under the conditions of 30°C, 100rpm, 30001x light and air bath, and the experimental data under the autotrophic culture conditions were obtained. Cultivate for 10 days, analyze the concentration of algae cells in the test shaker flask, measure the number of live cells therein with a cell counter, and analyze the total percentage of oil and fat in the algae cells under dry weight conditions with Soxhlet extraction.

Embodiment 2

[0038] The starting algae species is FY1# autotrophic Chlorella, and the culture condition is to add heterotrophic carbon source to the basic medium, add 0.02mmol / L Na 2 SO 3 and the bacterial slag pretreatment solution with a concentration of 3% (v / v); the expression of the concentration of the added substance here is based on the total volume of the medium, that is, the content of the added substance accounts for the total culture solution after the preparation of the culture solution is completed. Percentage by volume or number of moles or mass, etc., the same is true for other embodiments.

[0039] Among them, the source of bacterial residue is Klebsiella pneumoniae, which grows anaerobically. This bacterium uses glycerol as the only substrate and grows under anaerobic culture conditions. It can ferment and produce 1,3-propanediol. After cooking for 40 minutes, filter the filter cake of bacterial residue at normal temperature to obtain the filter cake of bacterial residue...

Embodiment 3

[0043] The domesticated algae species FY1X-9# obtained on the basis of Example 2 was subjected to an investigation experiment of adding glucose as a carbon source. The amount of glucose added was 30g / L, and other culture conditions were consistent with the heterotrophic domestication conditions. Cultured for 5 days, Analyze the concentration of algae cells in the test shaker flask, measure the number of viable cells therein with a cell counter, and analyze the percentage of oil and fat contained in the algae cells under the condition of dry weight by Soxhlet extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com