Fixing device and method for refractory material in strip steel heat treatment furnace

A technology for heat treatment furnaces and refractories, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of a large number of anchoring nails, a large number of welding materials and welding labor, a lot of labor and time, and save labor costs. , The effect of saving labor costs and saving welding materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

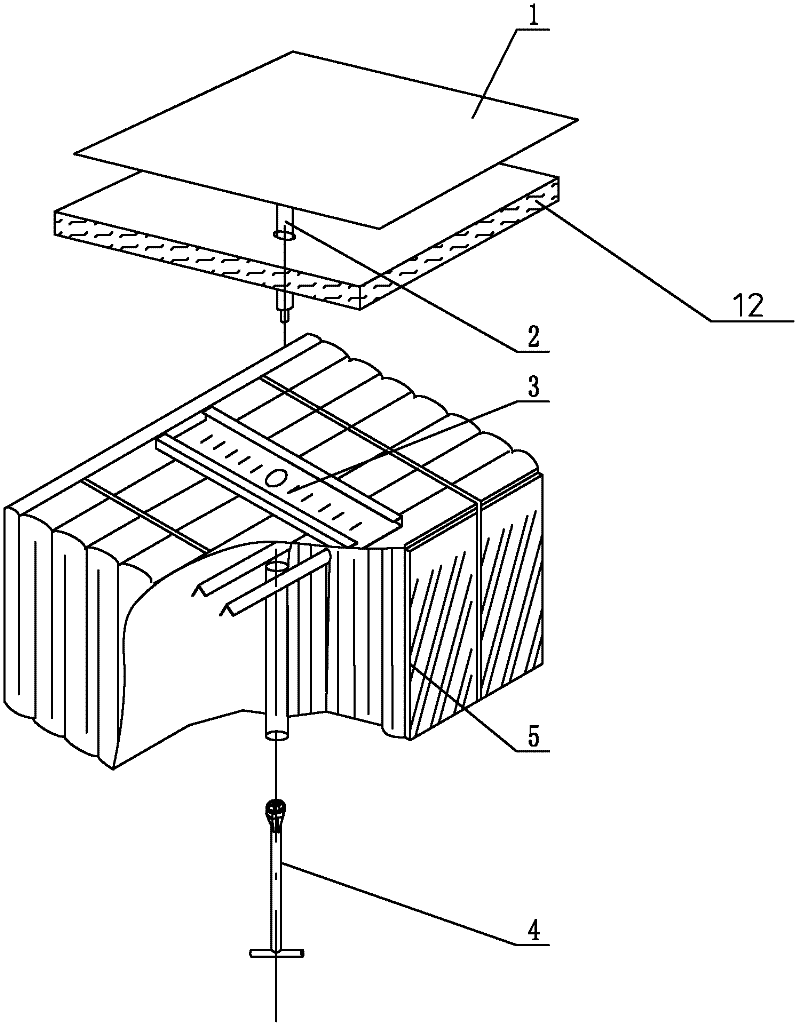

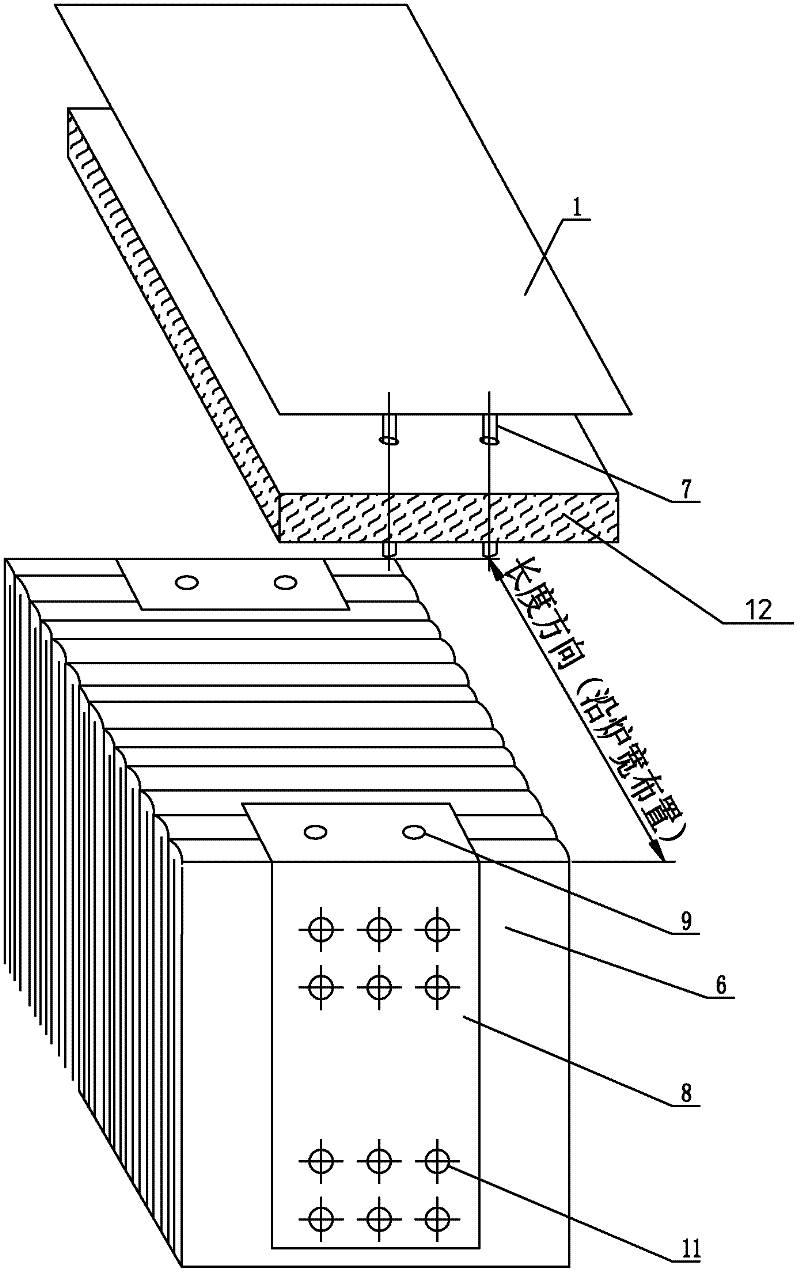

[0035] The present invention selects the refractory ceramic fiber folding block 6 to replace the current refractory ceramic fiber module 5 for the side wall and top of the heat treatment furnace. The only difference between the refractory ceramic fiber folded block and the fiber module is that there is no hanging structure inside the former. Therefore, the refractory ceramic fiber folded block is generally used in the bottom of the furnace.

[0036] refer to Figure 2-5 , the refractory ceramic fiber folding block provided by the present invention and its fixing method are as follows:

[0037] The first step is to draw a line according to the requirements of the refractory design drawing, and specify the welding position of the supporting bolt 7;

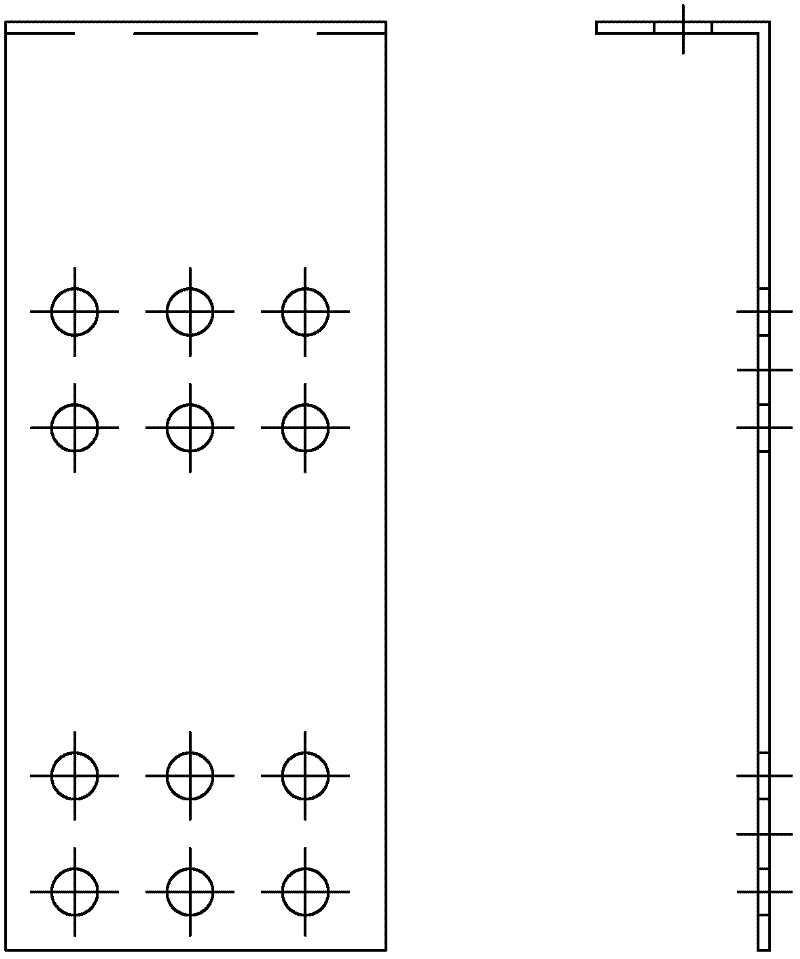

[0038] In the second step, the supporting bolts are welded on the steel plate of the furnace shell, and then the L-shaped steel plate 8 is inserted into the bolts through the positioning holes 9 (the number of positioning holes in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com