Piling construction equipment for large steel pipe piles of seaborn intertidal zone wind power station

A construction equipment, technology of steel pipe piles, applied in the direction of sheet pile walls, foundation structure engineering, ships

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

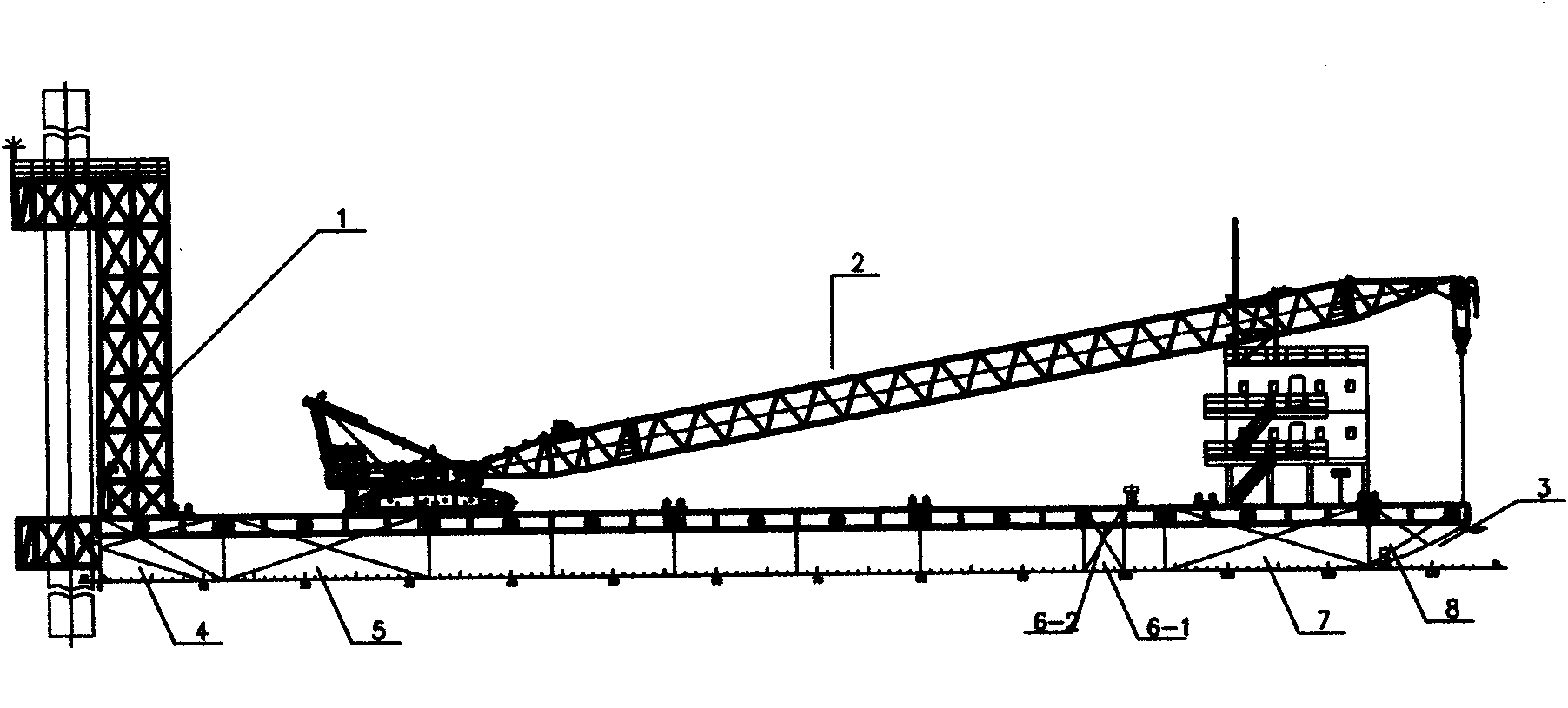

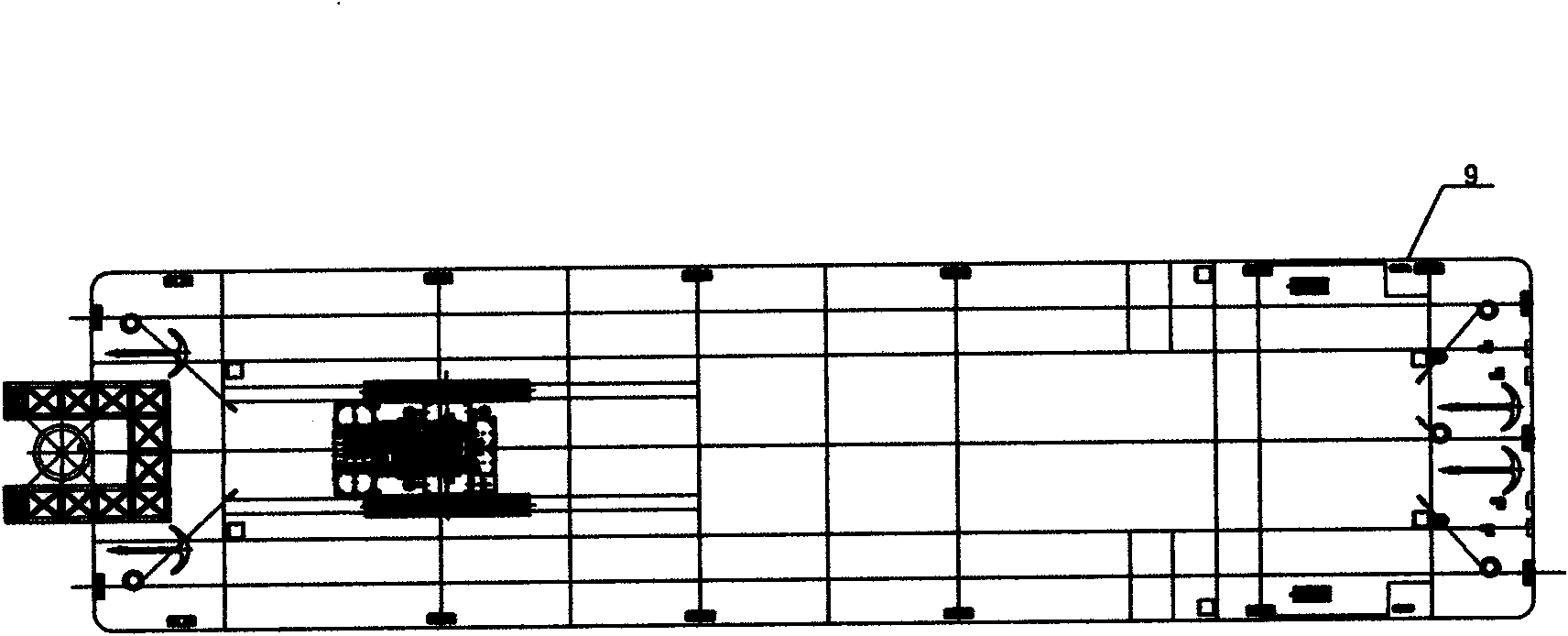

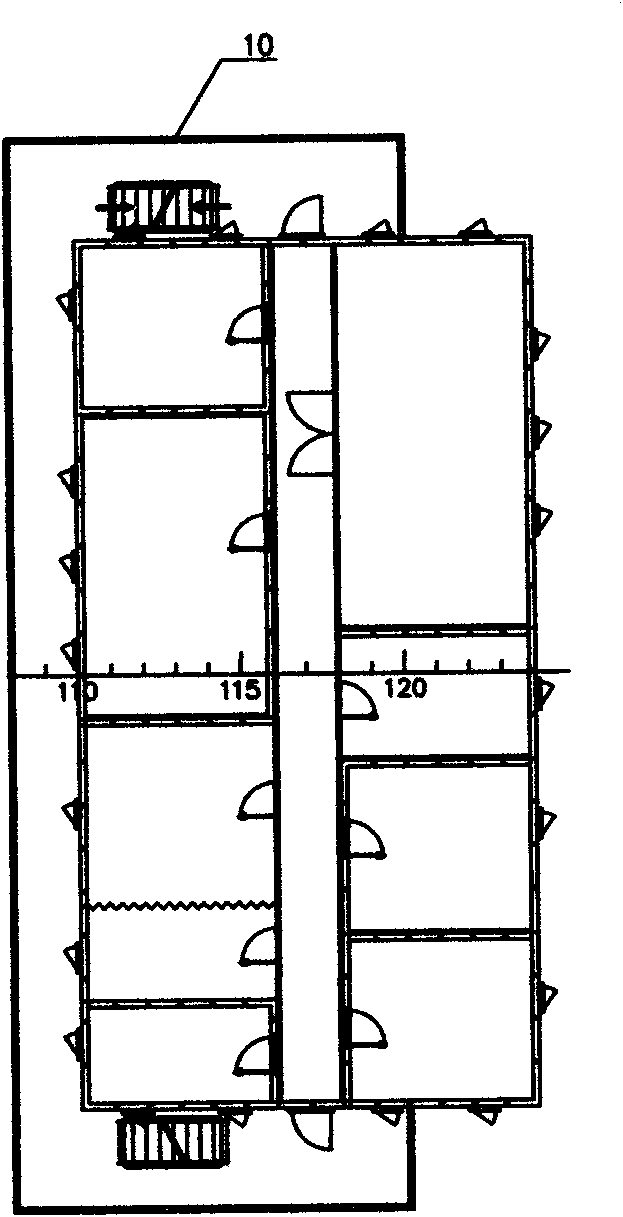

[0012] see Figure 1-4 , the specific embodiment adopts the following technical solutions: it is composed of guide frame 1, crawler crane 2, hull 3, two tail adjustment water tanks 4, two No. two ballast tanks 5, fuel tank 6-1, fresh water tank 6 -2. Two No. 1 ballast tanks 7, two first adjustment water tanks 8, main deck 9, A deck 10, and B deck 11; two tail adjustment water tanks 4 are respectively arranged on the left and right sides of the piling construction equipment , the fuel tank 6-1 and the fresh water tank 6-2 are respectively arranged on the left and right sides of the piling construction equipment, the two No. Set on the left and right sides of the piling construction equipment, the two tail adjustment water tanks 4 are set on the left side of the two No. 2 ballast tanks 5, the fuel tank 6-1 and the fresh water tank 6-2 are set on the two No. On the left side of cabin 7, two first adjustment water tanks 8 are arranged on the right side of No. 1 ballast tank 7, gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com