Puffed compound feed for bighead carp and preparation method for puffed compound feed

A technology for extruding compound feed and bighead carp, which is applied to the field of extruding compound feed and its preparation, can solve the problems of low digestion and absorption rate, waste, inconvenient feeding of bighead carp, etc., and achieves a simple preparation method, reduced waste and no toxic effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

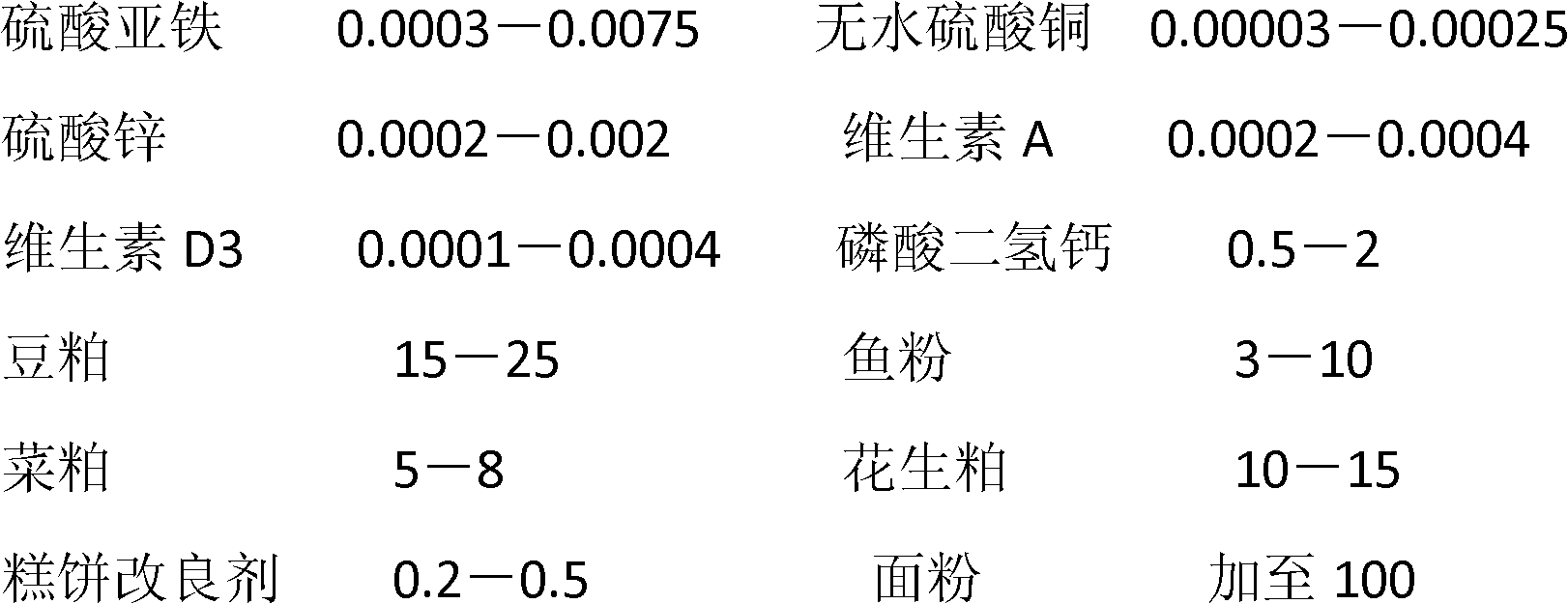

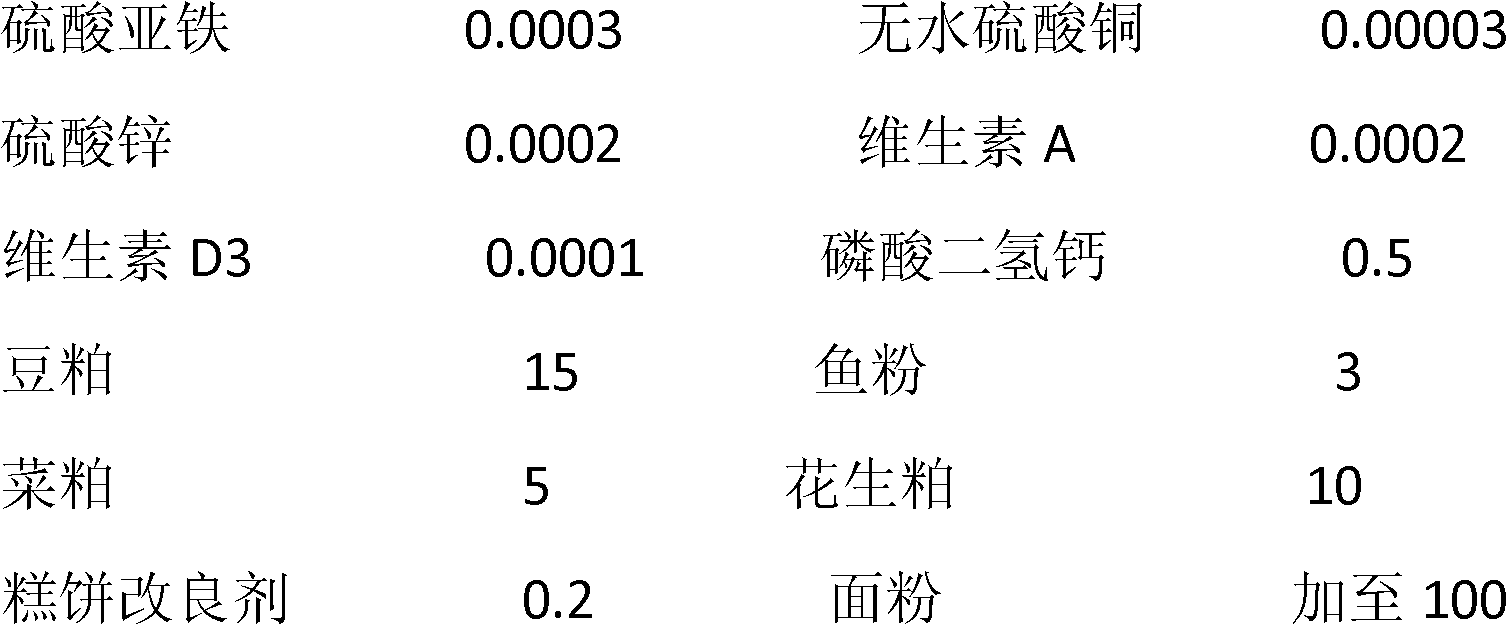

[0011] The extruded compound feed suitable for bighead carp that the present embodiment provides consists of the following components in weight percentage:

[0012]

[0013] Now taking the preparation of 100 kg of extruded compound feed suitable for bighead carp as an example, the preparation method of the extruded compound feed suitable for bighead carp that is provided by the present embodiment is set forth as follows:

[0014] First, the operator weighs 0.0003 kg of ferrous sulfate, 0.00003 kg of anhydrous copper sulfate, 0.0002 kg of zinc sulfate, 0.0002 kg of vitamin A, 0.0001 kg of vitamin D3, 0.5 kg of calcium dihydrogen phosphate, 15 kg of soybean meal, 3 kg of fish meal, 5 kg of rapeseed meal, 10 kg of peanut meal, 0.2 kg of pastry improver and 66.29917 kg of flour, and then preliminarily crush other components except flour, vitamin A, and vitamin D3 to 40-50 mesh with a pulverizer Granularity, then finely pulverized to 90-100 mesh particle size, then put into the ...

Embodiment 2

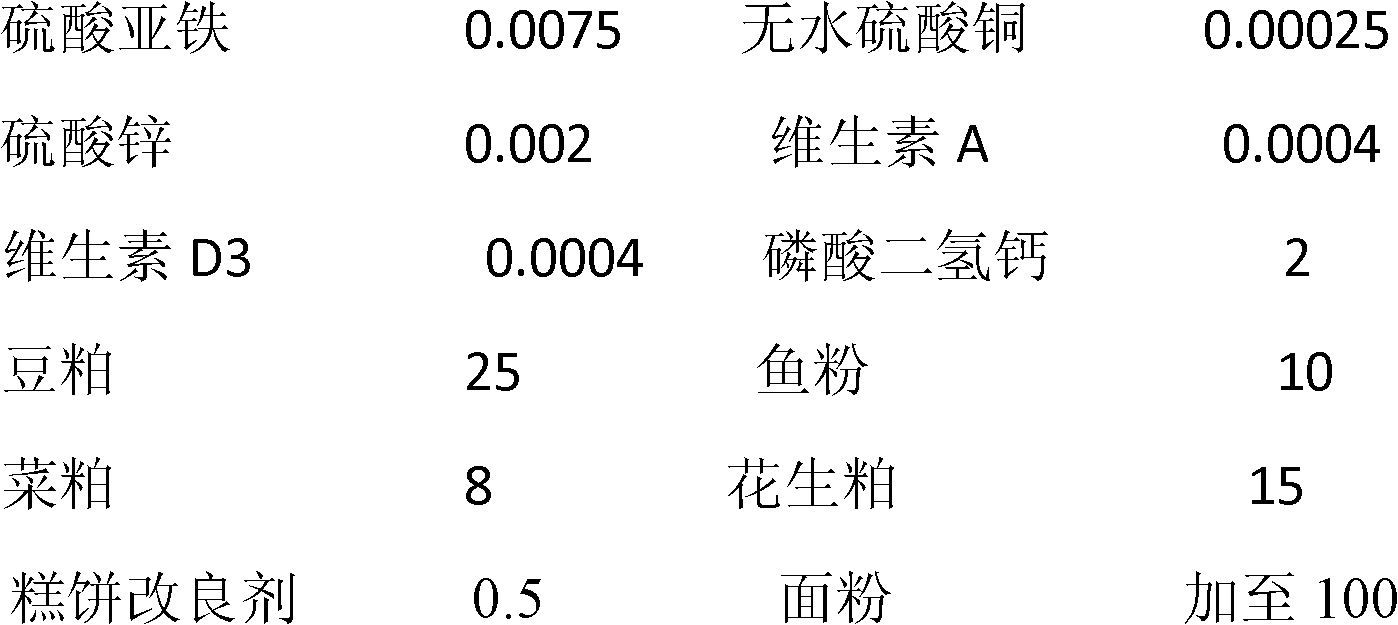

[0016] The extruded compound feed suitable for bighead carp that the present embodiment provides consists of the following components in weight percentage:

[0017]

[0018] Now taking the preparation of 100 kg of extruded compound feed suitable for bighead carp as an example, the preparation method of the extruded compound feed suitable for bighead carp that is provided by the present embodiment is set forth as follows:

[0019] First, the operator weighs 0.0075 kg of ferrous sulfate, 0.00025 kg of anhydrous copper sulfate, 0.002 kg of zinc sulfate, 0.0004 kg of vitamin A, 0.0004 kg of vitamin D3, 2 kg of calcium dihydrogen phosphate, 25 kg of soybean meal, 10 kg of fish meal, 8 kg of rapeseed meal, 15 kg of peanut meal, 0.5 kg of pastry improver and 39.48585 kg of flour, and then preliminarily crush other components except flour, vitamin A and vitamin D3 to 40-50 mesh Granularity, then finely pulverized to 90-100 mesh particle size, then put into the mixer, then add vitam...

Embodiment 3

[0021] The extruded compound feed suitable for bighead carp that the present embodiment provides consists of the following components in weight percentage:

[0022]

[0023] Now taking the preparation of 100 kg of extruded compound feed suitable for bighead carp as an example, the preparation method of the extruded compound feed suitable for bighead carp that is provided by the present embodiment is set forth as follows:

[0024] First, the operator weighs 0.0036 kg of ferrous sulfate, 0.00011 kg of anhydrous copper sulfate, 0.001 kg of zinc sulfate, 0.0003 kg of vitamin A, 0.0003 kg of vitamin D3, 1.2 kg of calcium dihydrogen phosphate, 20 kg of soybean meal, 7 kg of fish meal, 7 kg of rapeseed meal, 12 kg of peanut meal, 0.4 kg of pastry improver and 52.39469 kg of flour, and then preliminarily crush other components except flour, vitamin A and vitamin D3 to 40-50 mesh with a pulverizer Granularity, then finely pulverized to 90-100 mesh particle size, then put into the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com