Benefication method for recovering ilmenite from iron tailings in Shandong area

A beneficiation method and titanium recovery technology, applied in chemical instruments and methods, flotation, wet separation, etc., to achieve reliable technology, simple process flow, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

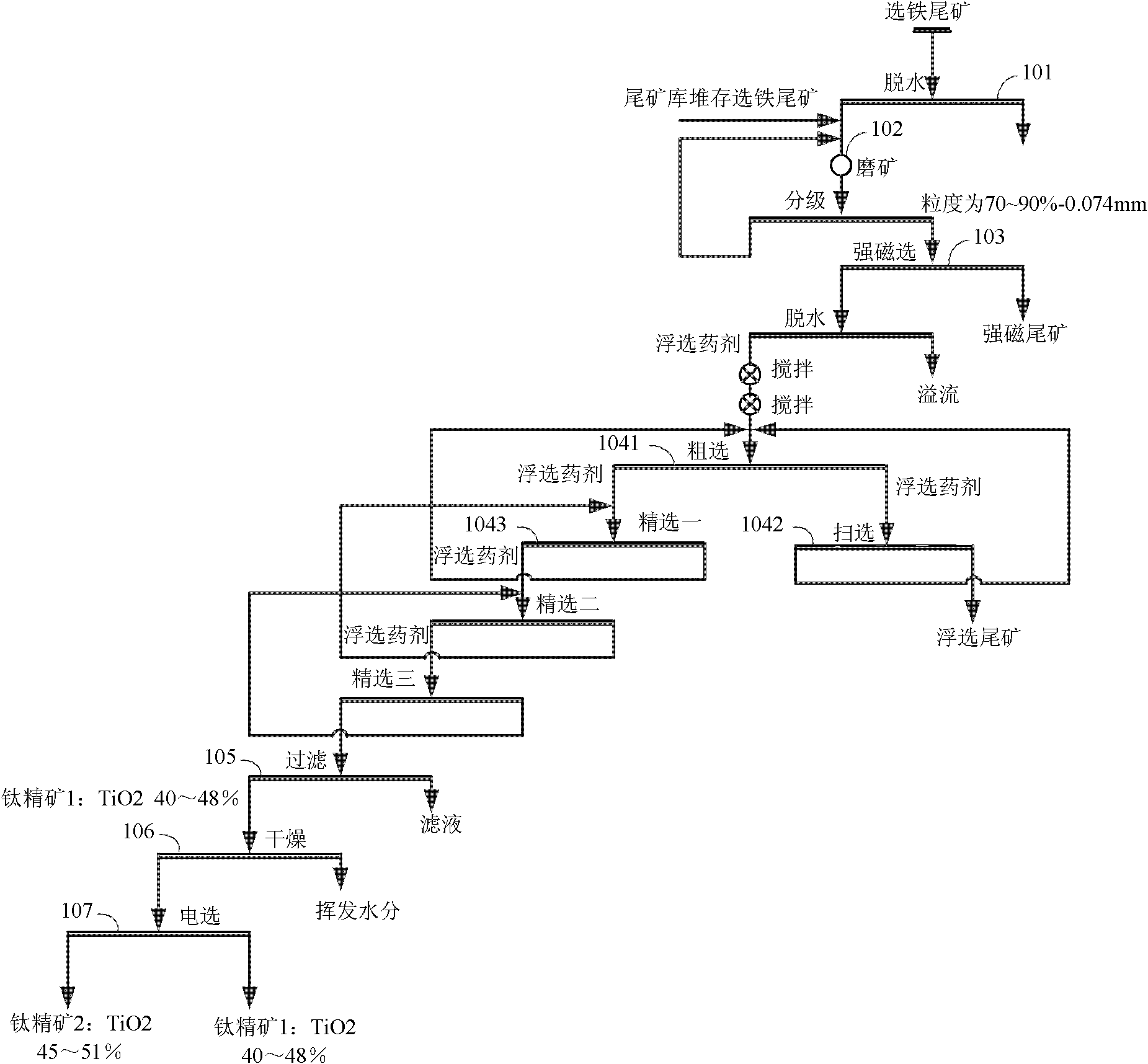

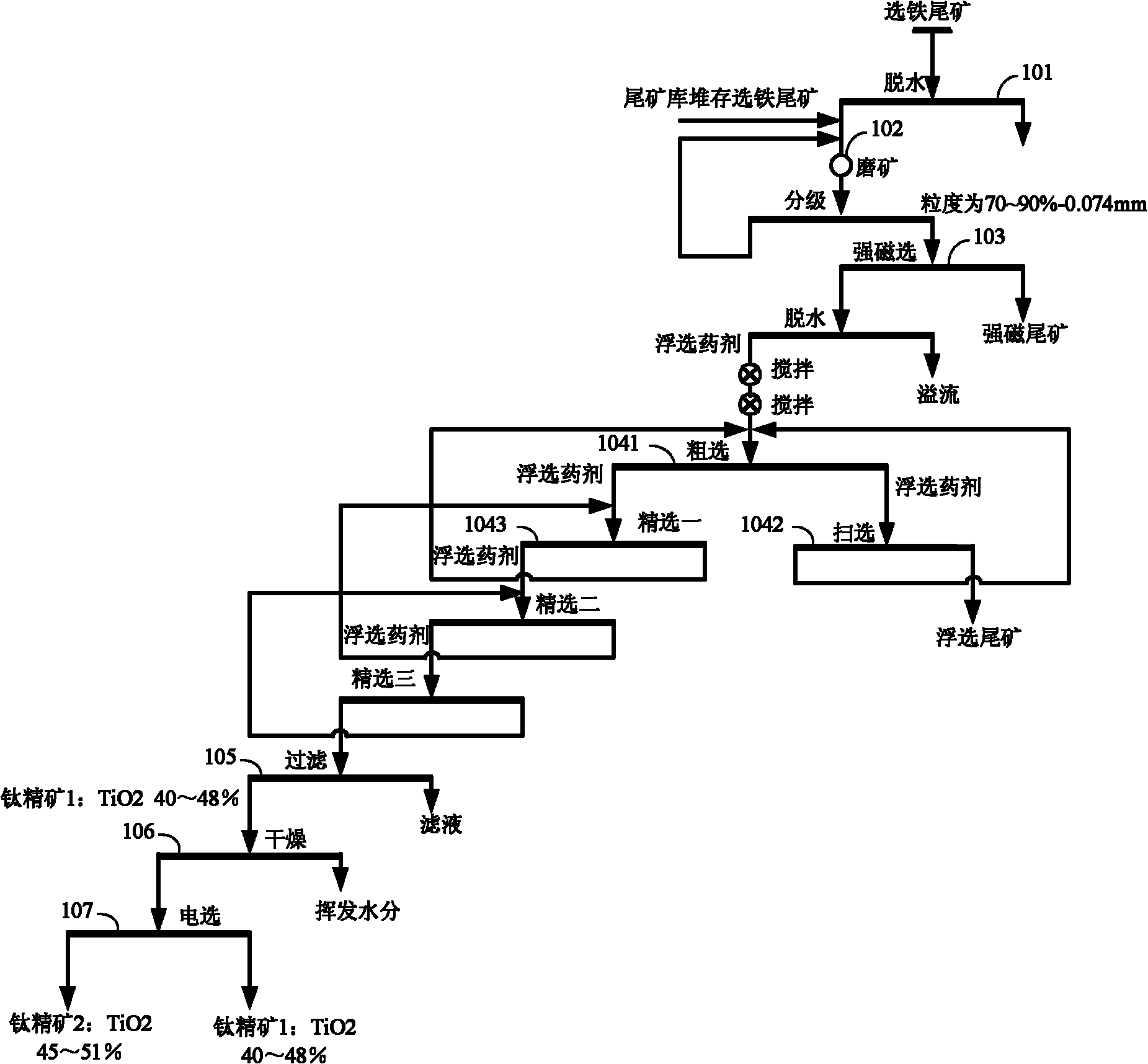

[0027] The invention integrates the advantages of magnetic separation, flotation and electric separation, and recovers the ilmenite from the iron-separation tailings by means of magnetic separation, flotation and electric separation.

[0028] Such as figure 1 Shown is the flow chart of the ore dressing method for recovering ilmenite in the iron tailings in Shandong area of the present invention. The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0029] Step 101: dehydrating the iron-selection tailings;

[0030] The iron tailings are pumped to the titanium beneficiation plant. Usually, the water content in the iron tailings is high, and the iron tailings need to be dehydrated first. At the same time, the iron dressing tailings that have been accumulated in the tailings pool for many years can be recycled.

[0031] Step 102: Grinding the iron beneficiation tailings, the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com