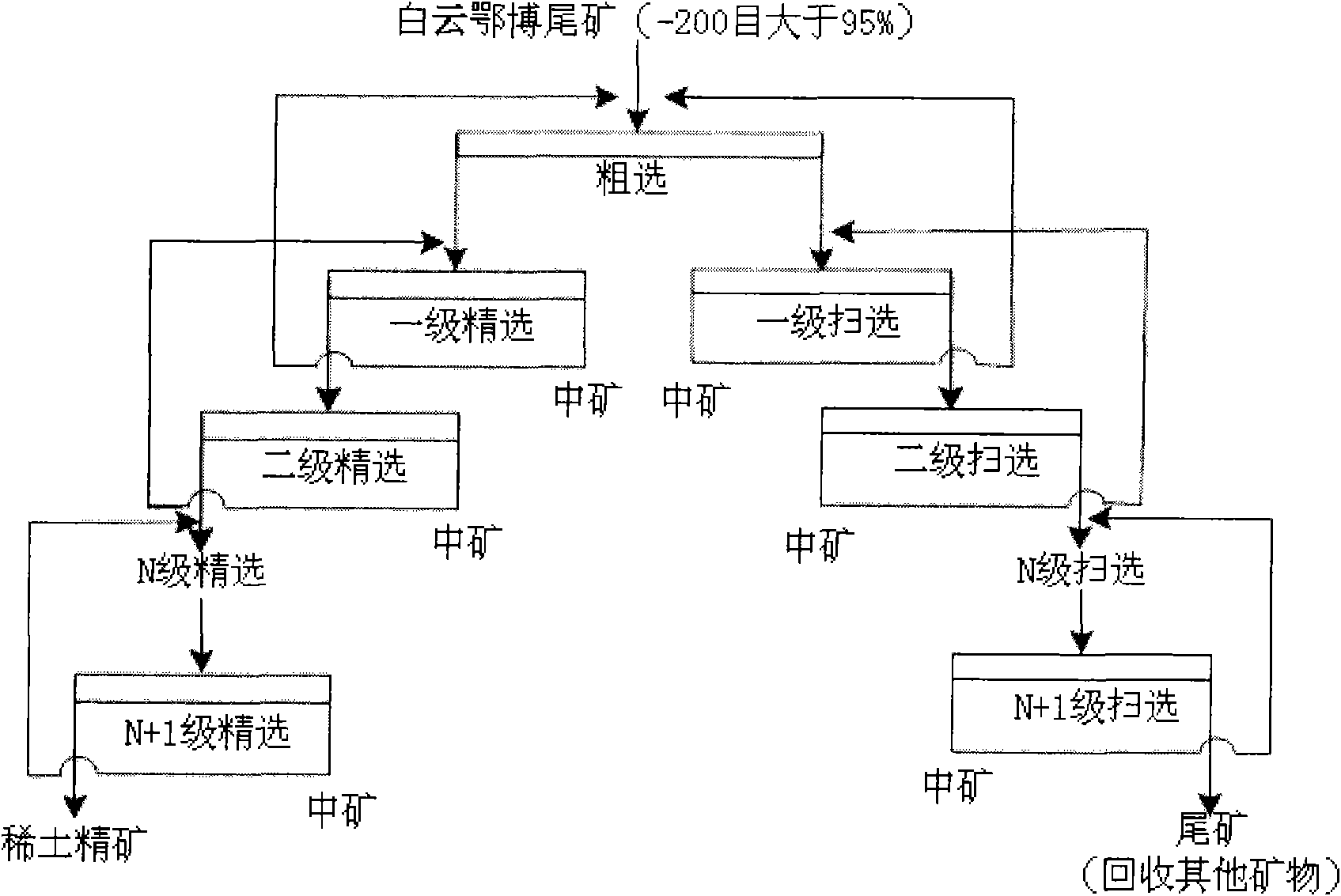

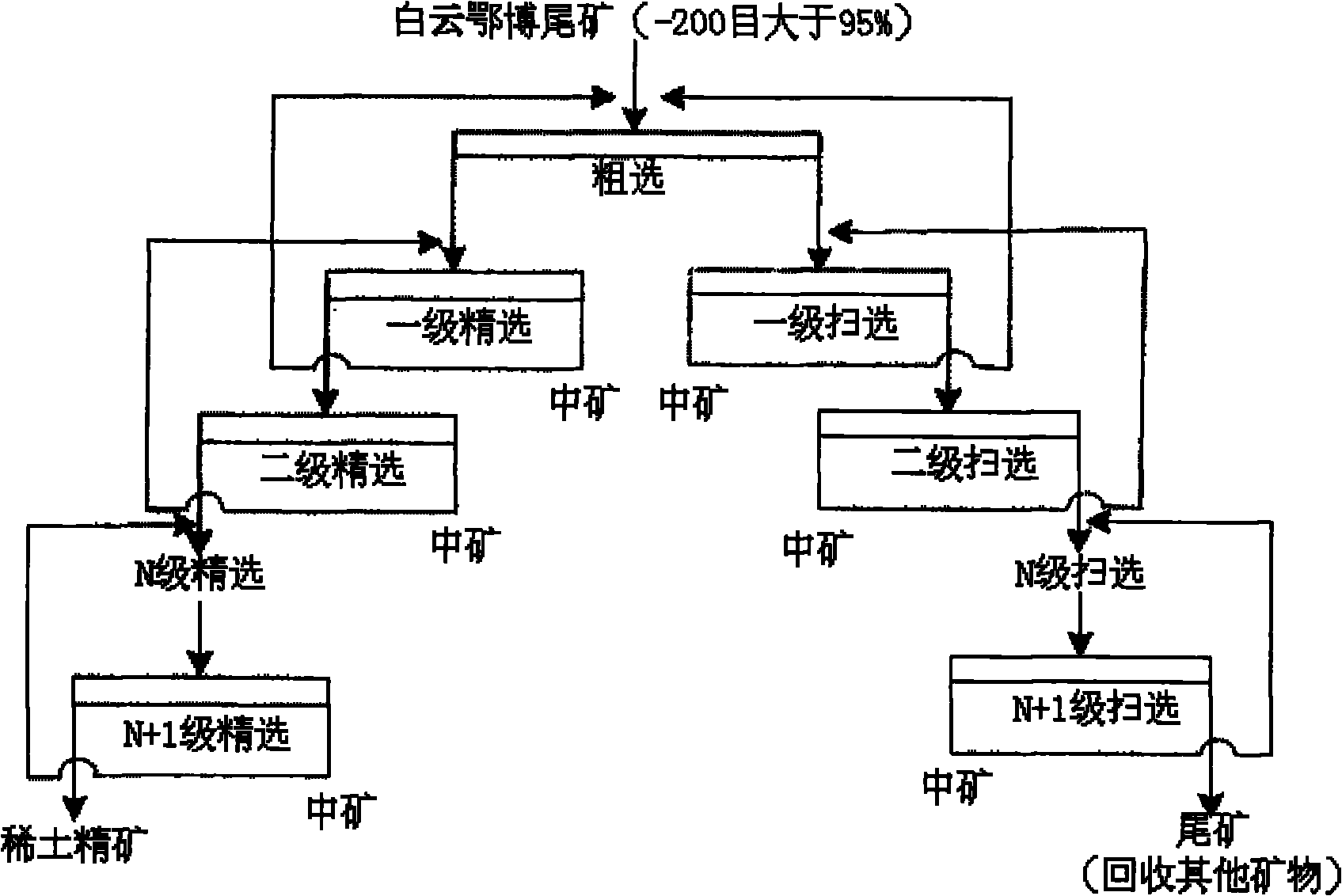

Method for flotation of rare earth from Baiyunebo tailings

A technology for tailings and rare earths, applied in flotation, solid separation and other directions, can solve the problems of not effectively recovering useful minerals, insufficient recovery rate of rare earth minerals, only about 70%, etc., and achieves low production cost, high recovery rate, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] For the Baiyun Obo tailings with a rare earth REO grade of 7.02%, using the process technology of the present invention, the tailings are firstly ground until the particle size is -200 mesh and account for more than 95%, and then roughing, four times of beneficiation and The closed-circuit circulation beneficiation process of one-time scavenging performs rare earth flotation operations on the tailings.

[0022] 1) Grinding: use a ball mill to grind the Baiyun Obo tailings until the particle size is -200 mesh, accounting for more than 95%.

[0023] 2) Rough separation: add Baiyan Obo tailings with a rare earth REO grade of 7.02% into the rough separation tank, add water to mix and adjust the slurry to control the mass concentration of the slurry at 46% and start stirring. The temperature of the slurry is 39°C; while stirring Add water glass 1.5kg / t, LF8#2.6kg / t, 318 # The pH of the slurry is 0.12kg / t, and the pH of the slurry is 9.6. The roughed rare earth concentrate a...

Embodiment 2

[0030] For the Baiyun Obo tailings with a rare earth REO grade of 14.36%, using the process technology of the present invention, the tailings are firstly ground until the particle size is -200 mesh and account for more than 95%, and then the primary roughing, three-time beneficiation and secondary The closed-circuit circulation beneficiation process of secondary sweeping is used to perform flotation of rare earth on the tailings.

[0031] 1) Grinding: Use a ball mill to grind the Baiyun Obo tailings until the particle size is -200 mesh, accounting for more than 95%;

[0032] 2) Rough separation: Add Baiyun Obo tailings with rare earth REO grade of 14.36% into the rough separation tank, add water to mix and adjust the pulp to control the pulp concentration at 68% and start stirring. The temperature of the pulp is 70°C; while stirring Add 3.2kg / t of water glass, 3.6kg / t of H2O5, 0.14kg / t of No. 2 oil, and 10.4 of the pH of the slurry to obtain roughed rare earth concentrate and ...

Embodiment 3

[0039] For the Baiyun Obo tailings with a rare earth REO grade of 2.97%, using the process technology of the present invention, the tailings are firstly ground until the particle size is -200 mesh, accounting for more than 95%, and then roughed once and five times selected The closed-loop beneficiation process uses the rare earth flotation operation on the tailings.

[0040] The amount of agent added during flotation is calculated by weight ratio: rough selection: water glass 0.4kg / t, LF10#3.5kg / t, 318 # 0.15kg / t; Yijing: water glass 0.6kg / t, LF10#2.2kg / t, 318 # 0.06kg / t; Erjing: water glass 0.5kg / t, LF10#1.3 / t, 318 # 0.05kg / t; Sanjing: water glass 0.2kg / t, LF10#1.2kg / t, 318 # 0.05kg / t; four essences: water glass 0.4kg / t, LF10#1.5kg / t, 318 # 0.05kg / t; Wujing: water glass 0.2kg / t, LF10#0.8kg / t, 318 # 0.05kg / t. The mass concentration of the roughing pulp is controlled at 30%, the pulp temperature is 63°C, and the pH of the pulp is 9.0; the mass concentration of the refined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com