Calcined lime conveying system

A conveying system and quicklime technology, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve problems such as ash leakage, slow conveying of raw ash, easy jamming of air locks, etc., to facilitate maintenance and reduce wind blowing link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

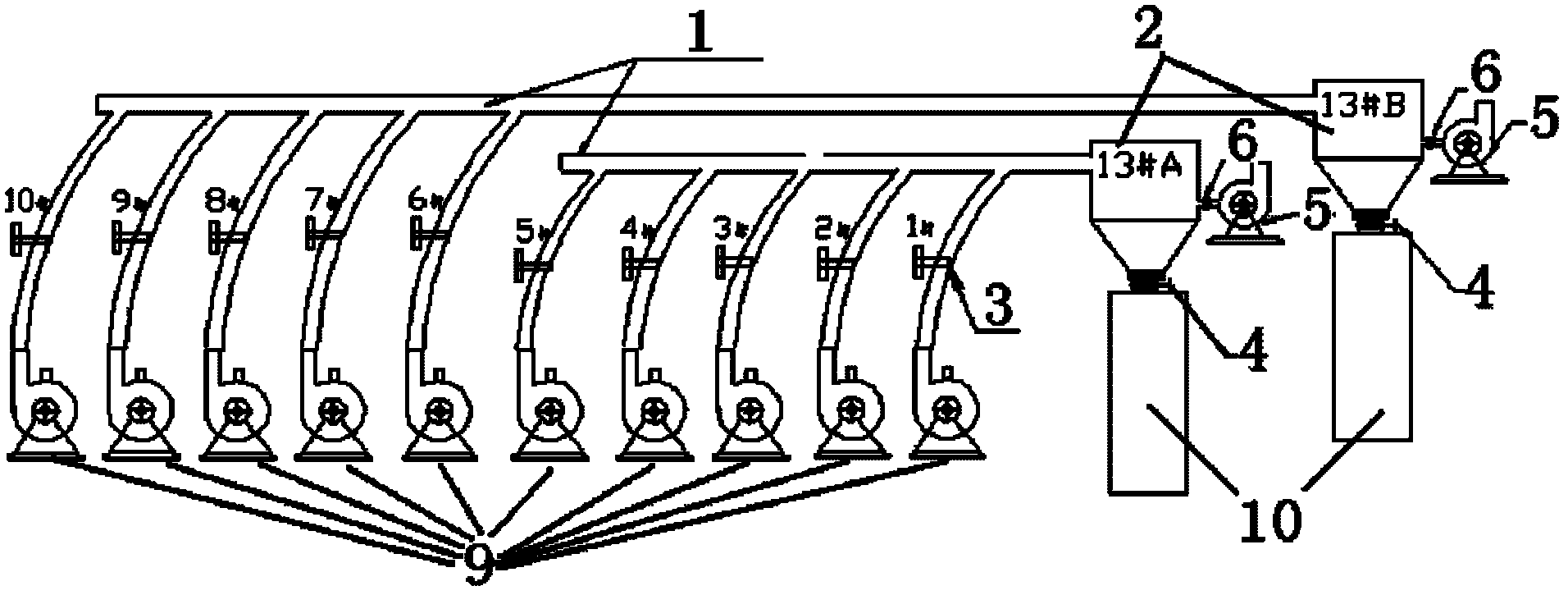

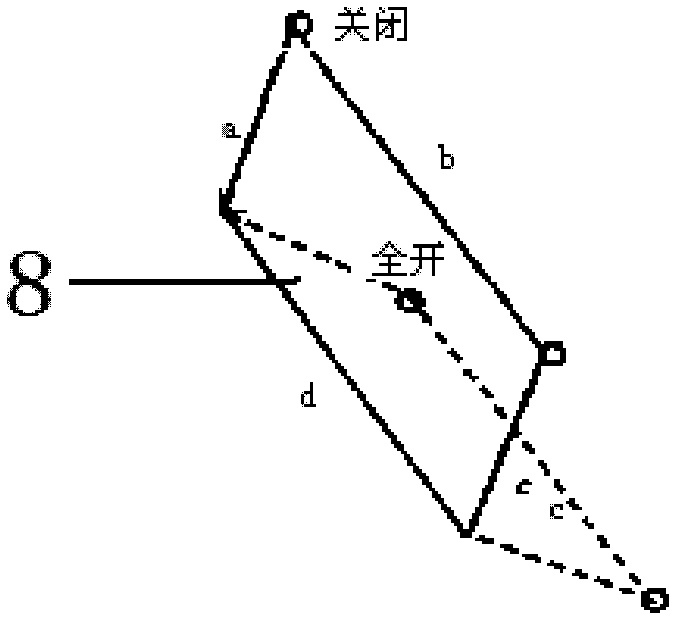

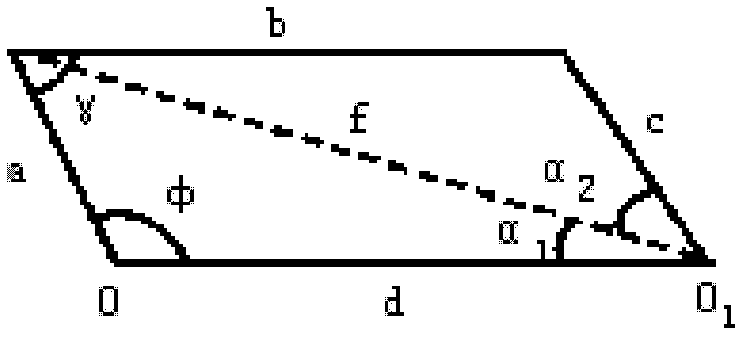

[0025] according to Figure 1-4 As shown, the technical solution provided by the present invention is a conveying system for quicklime, including a fixed frame, a conveying main pipe 1 and a dust collector 2, the conveying main pipe 1 is installed on the fixed frame, and one end of the conveying main pipe 1 It is connected with the hammer machine 9, and the other end is connected with the dust remover 2, and the dust remover 2 is installed on the top of the raw ash bin 10. Two or more delivery main pipes 1 are installed on the fixed frame. An outlet branch pipe of the hammer machine 9 is provided between the delivery main pipe 1 and the hammer machine 9, and an electro-hydraulic plug valve 3 is arranged on the outlet branch pipe of the hammer machine 9. The conveying dust remover 2 is connected with the fan 5 through the bellows 6 . The fan 5 is provided with a damper actuator 8 . The fixed frame includes more than one pole, and cross arms are arranged between the poles. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com