Water-soluble hyperbranched epoxy resin and preparation method thereof

An epoxy resin, water-soluble technology, applied in the field of water-soluble hyperbranched epoxy resin and its preparation, can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

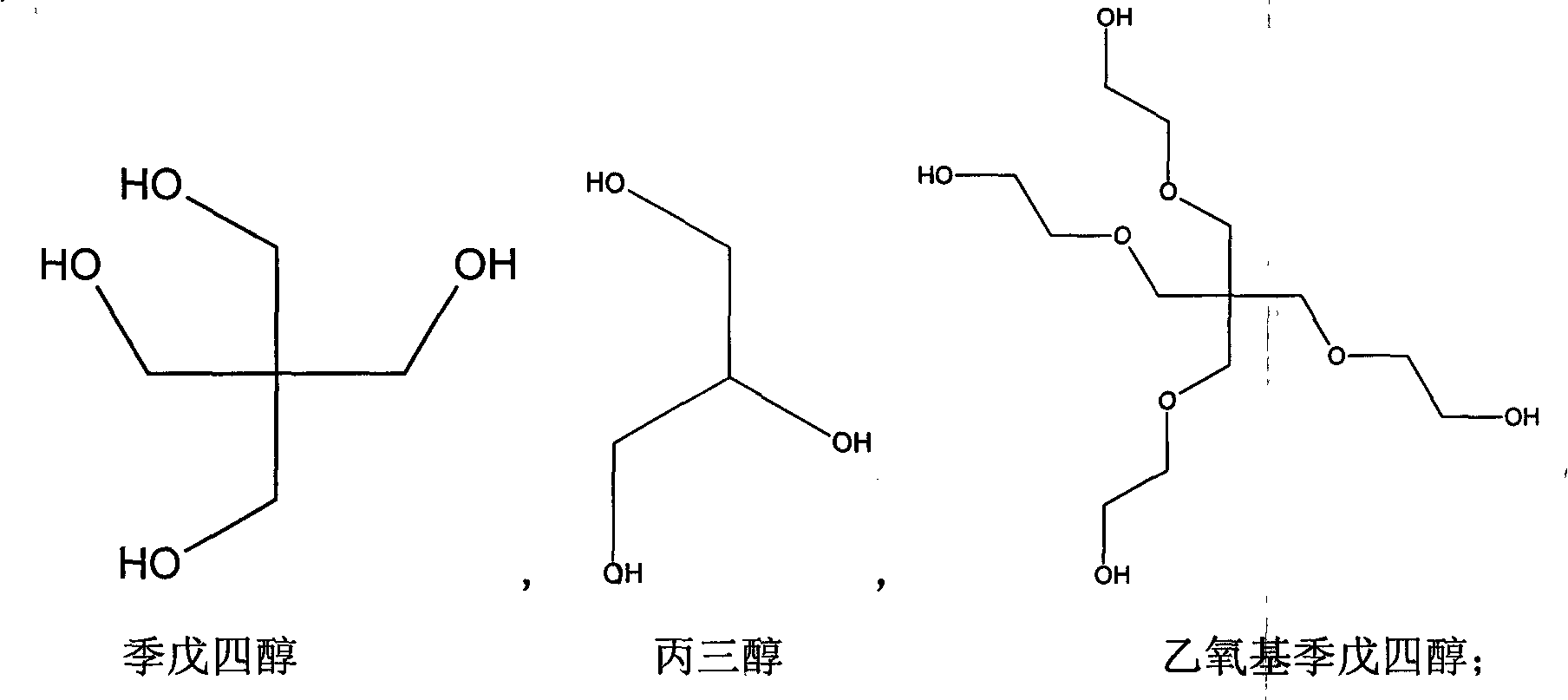

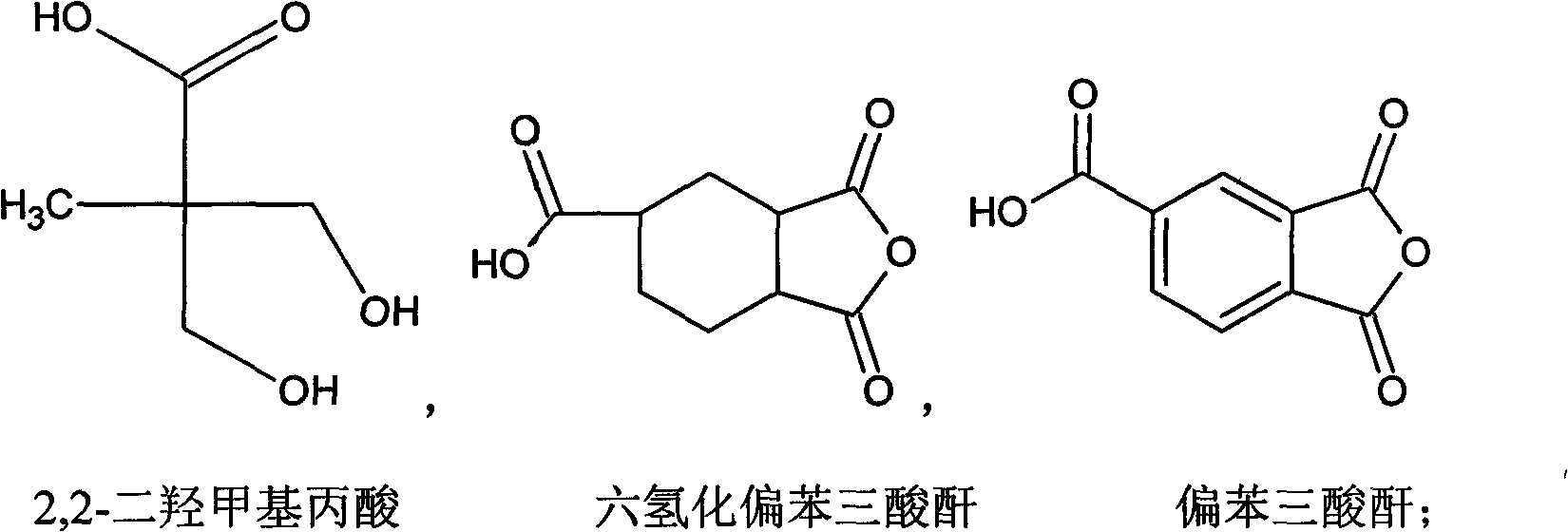

[0041] Prepare according to the water-soluble hyperbranched epoxy resin of the present embodiment through the following steps successively:

[0042] (1) Synthesis of water-soluble hyperbranched polymer: Add 1mol pentaerythritol, 11mol 2,2-dimethylolpropionic acid, 0.05mol p-toluenesulfonic acid into a four-necked flask, slowly heat up to 160-180 degrees, and pump Vacuum, make the vacuum degree of four-neck flask below 100Pa, constant temperature reaction 5 hours, obtain water-soluble hyperbranched polymer melt;

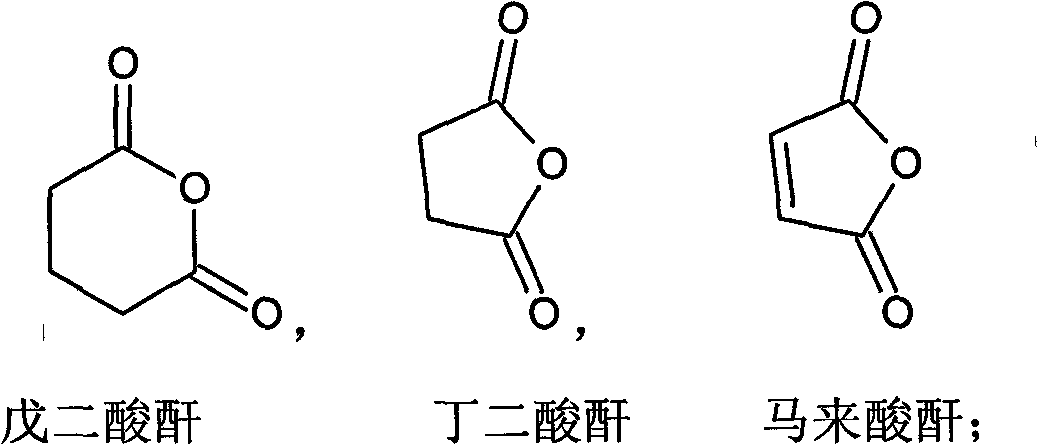

[0043] (2) Functional modification of water-soluble hyperbranched polymer end group: put 1mol maleic anhydride, 0.06mol toluenesulfonic acid and the above-mentioned water-soluble hyperbranched polymer into a four-necked flask, warm to 160-180 degrees, and vacuumize at the same time , making the vacuum degree of the four-necked flask below 100Pa, and reacting at a constant temperature for 4 hours, the terminal hydroxyl groups of the hyperbranched polymer and maleic anh...

Embodiment 2

[0048] According to the water-soluble hyperbranched epoxy resin of the embodiment of the present embodiment, it is prepared through the following steps once:

[0049] (1), the synthesis of water-soluble hyperbranched polymer: 1mol pentaerythritol, 32mol hexahydrotrimellitic anhydride, 0.1mol cetyltrimethylammonium bromide are added in the four-necked flask, slowly warming up to 160-180 degrees, pumping Vacuum, make the vacuum degree of four-neck flask below 100Pa, constant temperature reaction 9 hours, obtain water-soluble hyperbranched polymer melt;

[0050] (2), water-soluble hyperbranched polymer terminal functional modification: 0.5mol succinic anhydride, 0.06mol cetyltrimethylammonium bromide and the above-mentioned water-soluble hyperbranched polymer are dropped into a four-necked flask, and warm To 120-180 degrees, vacuum at the same time, so that the vacuum degree of the four-necked flask is below 100Pa, constant temperature reaction for 6-8 hours, part of the terminal...

Embodiment 3

[0054] According to the water-soluble hyperbranched epoxy resin of the present embodiment, it is prepared through the following steps once:

[0055] (1), the synthesis of water-soluble hyperbranched polymer: 1mol glycerol, 20mol trimellitic anhydride, 0.08mol boron trifluoride etherate complex are added in the four-necked flask, slowly warming up to 170-180 degrees, while evacuating, Keep the vacuum degree of the four-necked flask below 100Pa, and react at a constant temperature for 6-9 hours to obtain a water-soluble hyperbranched polymer melt;

[0056] (2), water-soluble hyperbranched polymer terminal functional modification: put 0.8mol maleic anhydride, 0.06mol boron trifluoride etherate complex and the above-mentioned water-soluble hyperbranched polymer into a four-necked flask, warm to 160 -180 degrees, vacuum at the same time, so that the vacuum degree of the four-necked flask is below 100Pa, and react at a constant temperature for 6-8 hours. The terminal hydroxyl groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com