Multi-grafted phenylethylene-ethylene-butylene copolymer and preparation method thereof

A technology of butene copolymerization and styrene, which is applied in the field of multi-component grafted styrene-ethylene-butene copolymer and its preparation, can solve problems such as poor compatibility, and achieves simple and easy operation process and simple production and preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

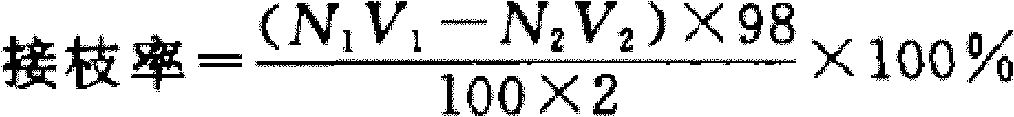

Method used

Image

Examples

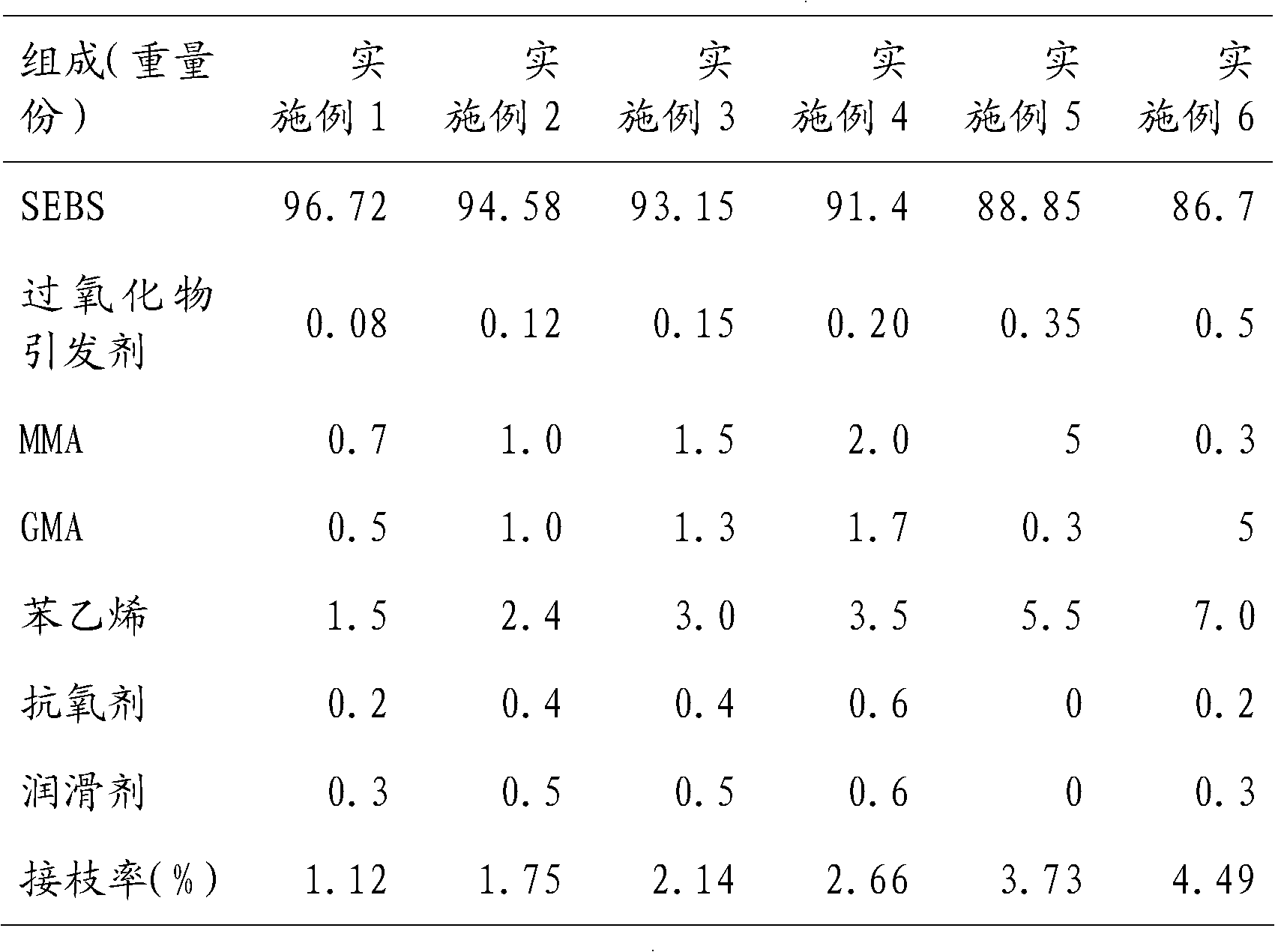

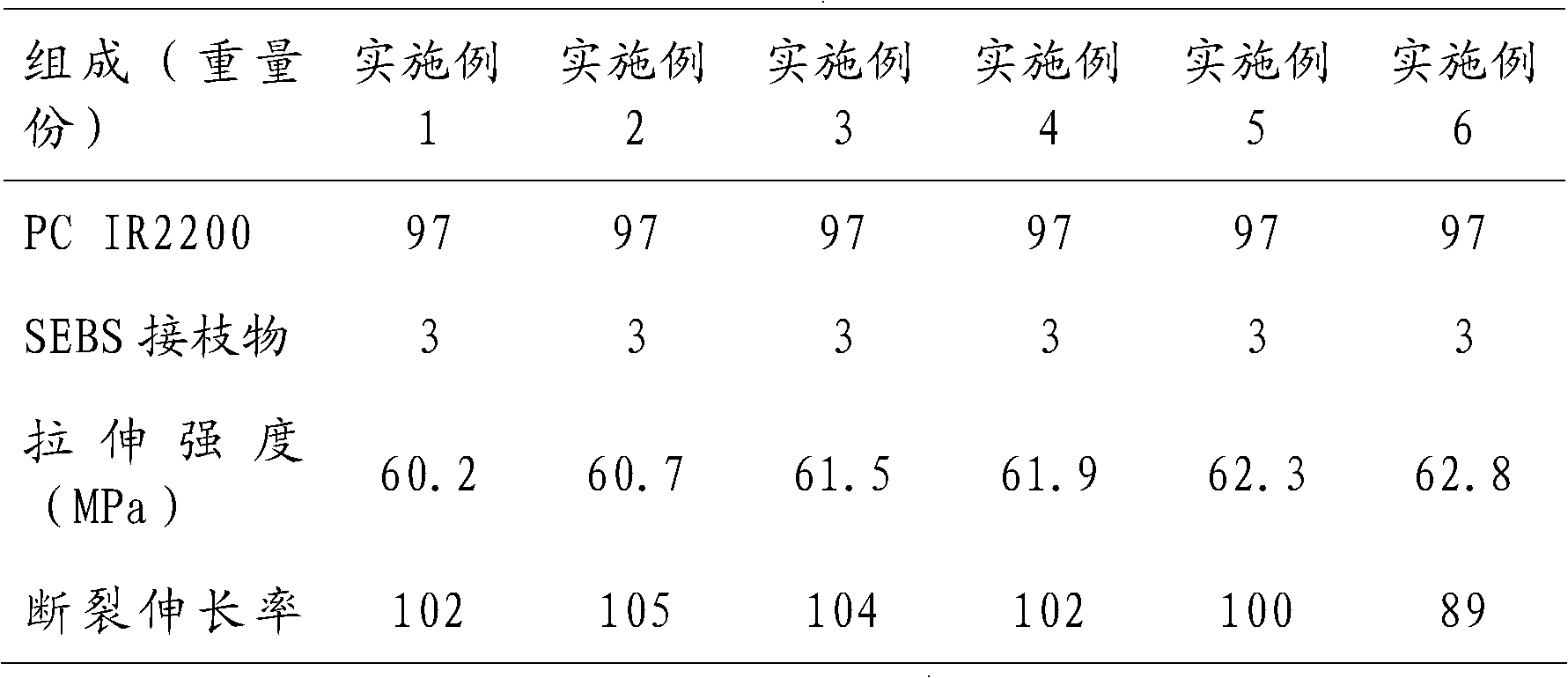

Embodiment 1

[0034] The multi-element grafted styrene-ethylene-butene copolymer of Example 1 is made from the following raw materials in parts by weight:

[0035] SEBS 1651 96.72 parts, DCP 0.08 parts, MMA 0.7 parts, GMA 0.5 parts, styrene 1.5 parts, 1010 0.1 parts, 168 0.1 parts, EBS 0.3 parts

[0036] Preparation method: Mix SEBS, peroxide initiator, MMA, GMA, co-reactant, antioxidant, and lubricant for 15 minutes; then melt and extrude through a twin-screw extruder to granulate into graft copolymer The process conditions of the twin-screw extruder are: the temperature in the first zone of the twin-screw extruder is 145℃, the temperature in the second zone is 150℃, the temperature in the third zone is 155℃, the temperature in the fourth zone is 160℃, and the temperature in the fifth zone is 165℃. The conveying time in the screw is 5 minutes and the pressure is 14 MPa.

Embodiment 2

[0037] The multi-element grafted styrene-ethylene-butene copolymer of Example 2 is made from the following raw materials in parts by weight:

[0038] SEBS 1654 94.58 parts, DCP 0.12 parts, MMA 1.0 parts, GMA 1.0 parts, styrene 2.4 parts, 1010 0.2 parts, 168 0.2 parts, EBS 0.5 parts

[0039] Preparation method: Mix SEBS, peroxide initiator, MMA, GMA, co-reactant, antioxidant, and lubricant for 15 minutes; then melt and extrude through a twin-screw extruder to granulate into graft copolymer The process conditions of the twin-screw extruder are: the temperature of the first zone of the twin-screw extruder is 145℃, the temperature of the second zone is 155℃, the temperature of the third zone is 165℃, the temperature of the fourth zone is 170℃, and the temperature of the fifth zone is 175℃. The conveying time in the screw is 4 minutes and the pressure is 15 MPa.

Embodiment 3

[0040] The meta-grafted styrene-ethylene-butene copolymer of Example 3 is made from the following raw materials in parts by weight:

[0041] SEBS 1651 93.15 parts, DCP 0.15 parts, MMA 1.5 parts, GMA 1.3 parts, styrene 3.0 parts, 1010 0.2 parts, 168 0.2 parts, EBS 0.5 parts

[0042] Preparation method: Mix SEBS, peroxide initiator, MMA, GMA, co-reactant, antioxidant, and lubricant for 15 minutes; then melt and extrude through a twin-screw extruder to granulate into graft copolymer The process conditions of the twin-screw extruder are: the temperature of the first zone of the twin-screw extruder is 145℃, the temperature of the second zone is 155℃, the temperature of the third zone is 165℃, the temperature of the fourth zone is 175℃, and the temperature of the fifth zone is 180℃. The conveying time in the screw is 3 minutes, and the pressure is 12 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com