Method for extracting onion enzyme from fistular onion stalk

A scallion and extract technology, applied in biochemical equipment and methods, enzymes, enzymes, etc., to achieve the effect of stable process quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Keep the scallions at a temperature of -4°C to 4°C for 12 hours to 24 hours;

[0020] (2) Add pH 6.5 Na to 350 grams of cooled scallion 2 HPO 4 and KH 2 PO 4 Mix 500 ml of phosphate buffer, 45 ml of glycerin, and 0.5 g of disodium ethylenediaminetetraacetic acid (EDTA), pre-cool at -4°C to 4°C for 12 hours, then add 0.001 g of 5'-pyridoxal phosphate; After homogenization at -4°C to 4°C; centrifuge at 0°C to 5°C at a speed of 6000 rpm to 8000 rpm for 20 minutes to 30 minutes to obtain the first solid phase and the first liquid phase; 500 ml of Na 2 HPO 4 and KH 2 PO 4 Phosphate buffer contains Na 2 HPO 4 3.5 g, with KH 2 PO 4 1.5 grams.

[0021] (3) Add 15% polyethylene glycol 8000 of the mass of the first liquid phase to the first liquid phase, and let it stand after stirring; at 0°C to 5°C, the rotating speed is 6000 rpm to 8000 rpm, and the time is 20 Minutes to 30 minutes for centrifugation to obtain protein precipitates and supernatant;

[0022] (4...

Embodiment 2

[0025] According to the above process steps

[0026] In step 2, raw materials: 350 grams of scallion white, 500 ml of Na at pH 6.5 2 HPO 4 and KH 2 PO 4 Phosphate buffer contains Na 2 HPO 4 6 grams, with KH 2 PO 4 4 g; 60 ml of glycerin, 2 g of disodium edetate, 0.005 g of pyridoxal 5'-phosphate

[0027] 25% polyethylene glycol of the mass of the first liquid phase in step 3.

[0028] 250 mL of Na at pH 6.5 from step 4 2 HPO 4 and KH 2 PO 4 Phosphate buffer contains Na 2 HPO 4 6 grams, with KH 2 PO 4 4 grams. Dialyzed 3 times.

[0029] Onion enzyme freeze-dried powder 6.0g

Embodiment 3

[0031] According to the above process steps

[0032] In step 2, raw materials: 350 grams of scallion white, 500 ml of Na at pH 6.5 2 HPO 4 and KH 2 PO 4 Phosphate buffer contains Na 2 HPO 4 4.8 g, with KH 2 PO 4 2.8 g; 100 ml of glycerin, 1 g of disodium edetate, 0.0025 g of pyridoxal 5'-phosphate

[0033] 30% polyethylene glycol 8000 by mass of the first liquid phase in step 3

[0034] 500 mL of Na at pH 6.5 from step 4 2 HPO 4 and KH 2 PO 4 Phosphate buffer contains Na 2 HPO 4 4.8 g, with KH 2 PO 4 2.8 grams.

[0035] 5.3 g of onion enzyme freeze-dried powder was obtained.

[0036] Polyethylene glycol 8000 (PEG8000) can be preferably used in the above-mentioned embodiment.

[0037] Above-mentioned technique shows: adopt the glycerin of the phosphate buffer of pH6~pH6.8, 9%~12% of phosphate buffer volume, the disodium edetate of 1~4 g / thousand milliliters of phosphate buffer by adopting extracting solution After homogenizing with 5'-pyridoxal phosphate and / or...

PUM

| Property | Measurement | Unit |

|---|---|---|

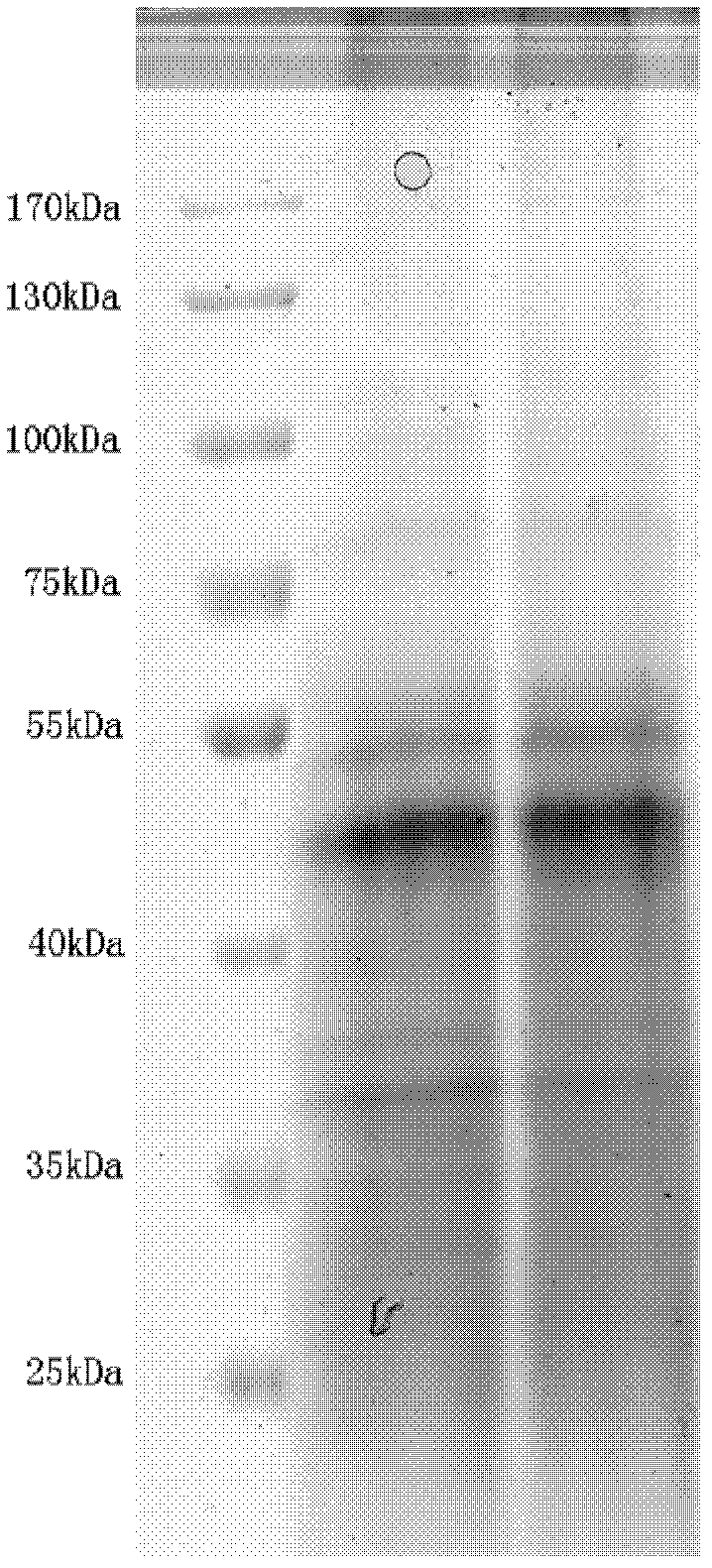

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com