HC (hydrocarbon compound) emission purifying system used for cold boot working condition of gasoline engine

A purification system and cold start technology, applied in the direction of machines/engines, exhaust treatment, mechanical equipment, etc., can solve the problems of long-term emission of harmful components without purification, harmful gas emissions, etc., to achieve internal structure improvement, effective Adsorption and purification, the effect of improving adsorption and purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

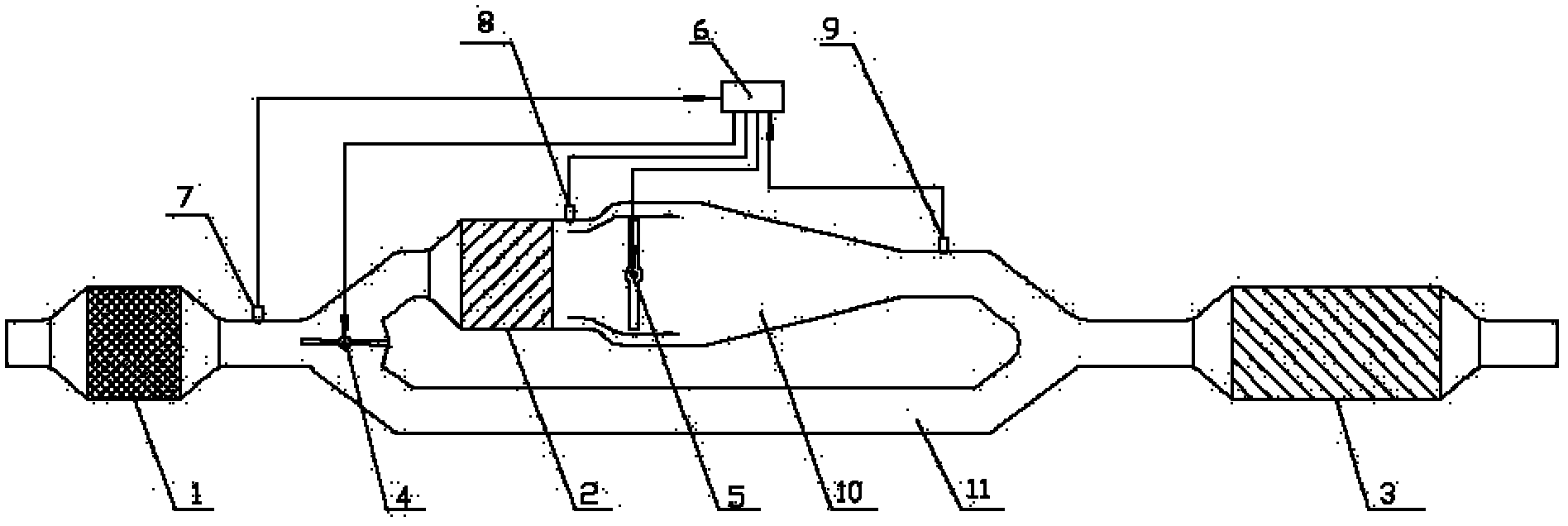

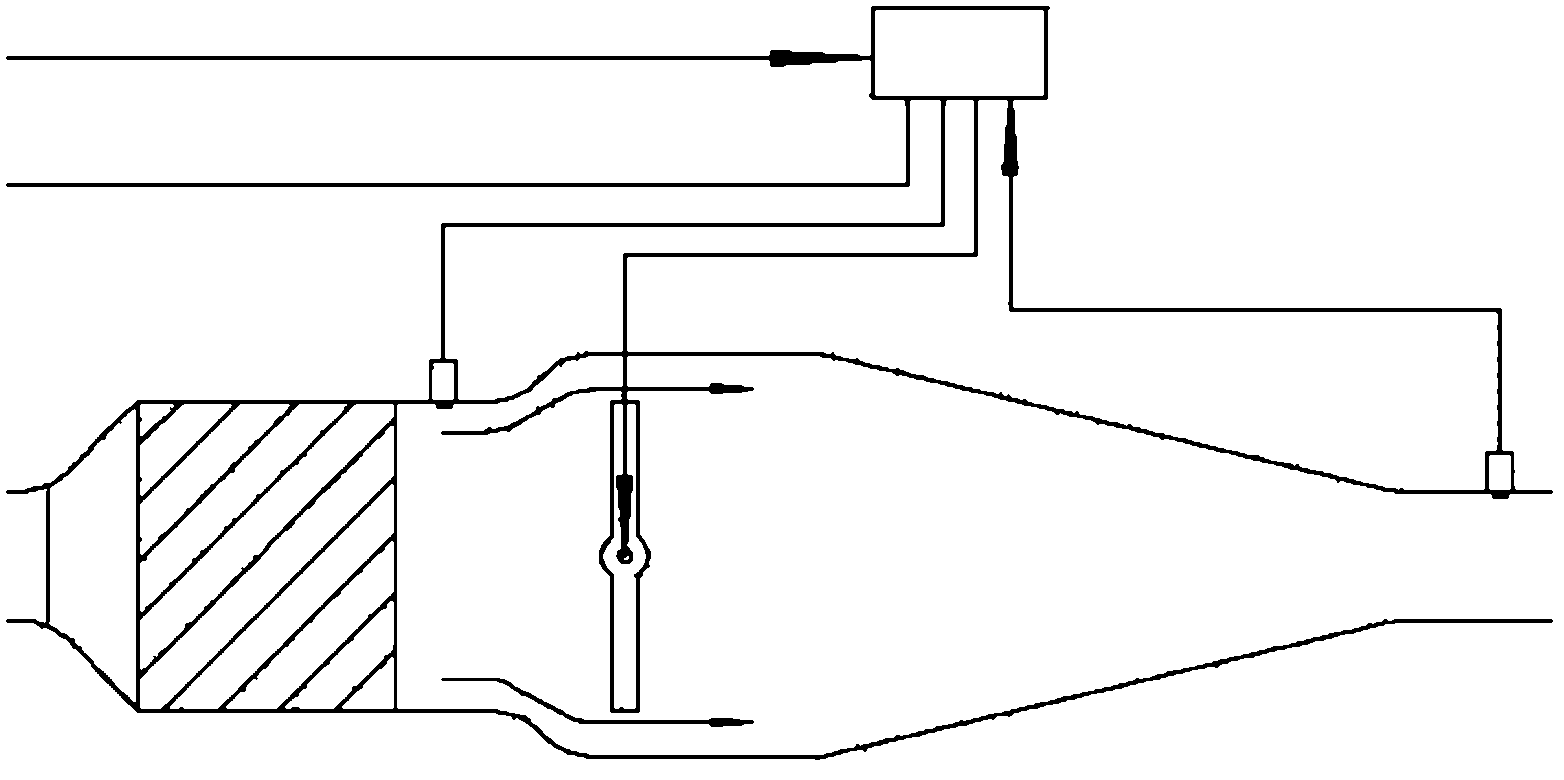

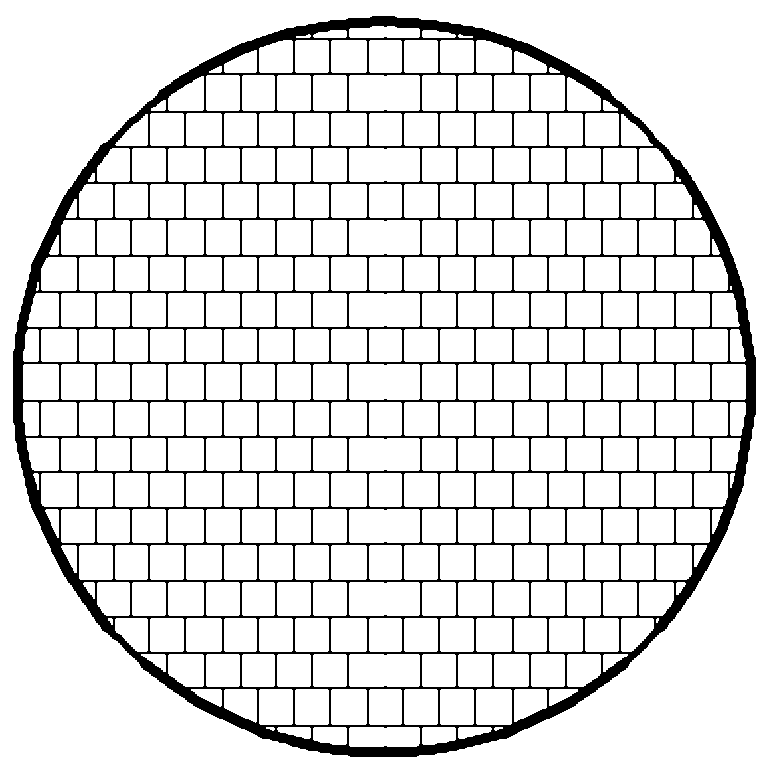

[0025] like image 3 As shown, both the adsorber 2 and the adsorption catalyst 3 use a mesh body (with 46.5 units / cm 2 , a cordierite monolithic support with a wall thickness of 0.0152 cm and a catalyst capacity of 1.0 L) structure. Wherein the schematic diagram of the unit cross-section of the adsorber 2 is shown as Figure 4 as shown, Figure 5 Its A-A plane sectional view. A certain amount of ZSM-5-3 zeolite and β-2 zeolite powder, silica sol and pure water are poured into a ball mill for grinding to obtain an adsorbent slurry solution. The slurry solution was coated on the cordierite carrier, and after the excess slurry solution in the air flow removal unit, it was dried in the air flow at 50°C for 30 minutes, then dried in the air flow at 150°C for 15 minutes, and then dried at 400°C Bake for 1 hour, repeat the above coating steps until the coating weight is 350g / dm after baking 3 . Then, the adsorbent slurry solution is again coated on the area of 30%~50% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com