Three-way catalytic reactor protecting system for automobile

A catalytic reactor and protection system technology, applied in the field of automobile three-way catalytic reactor protection system, can solve the impact of three-way catalytic reactor purification effect, reduce the service life of three-way catalytic reactor, damage to three-way catalytic reactor, etc. problems, to achieve the effect of improving heat dissipation, reducing energy consumption, and reducing the difficulty of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

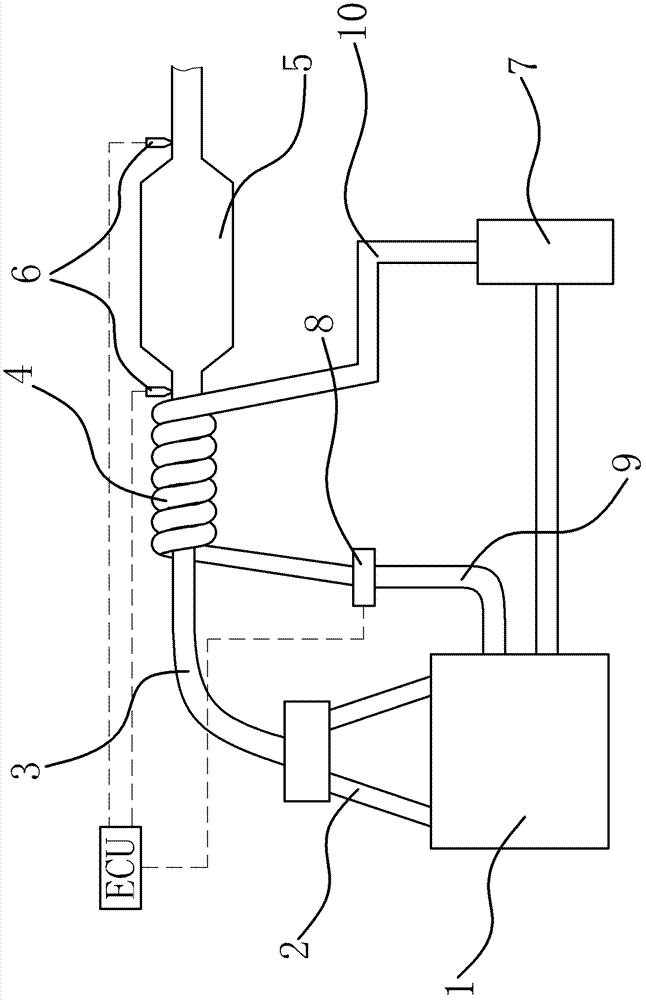

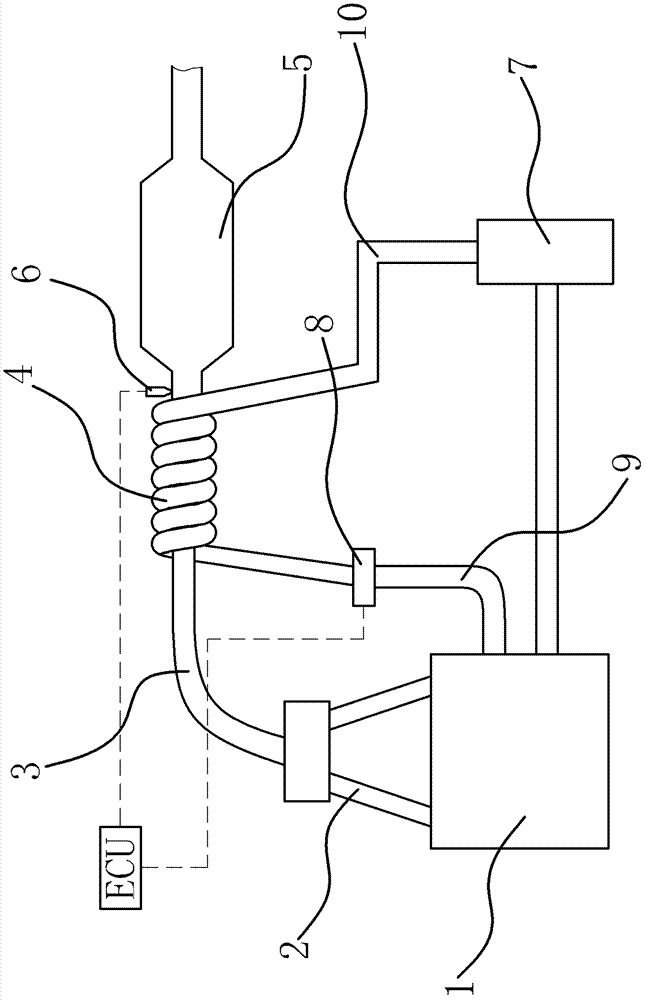

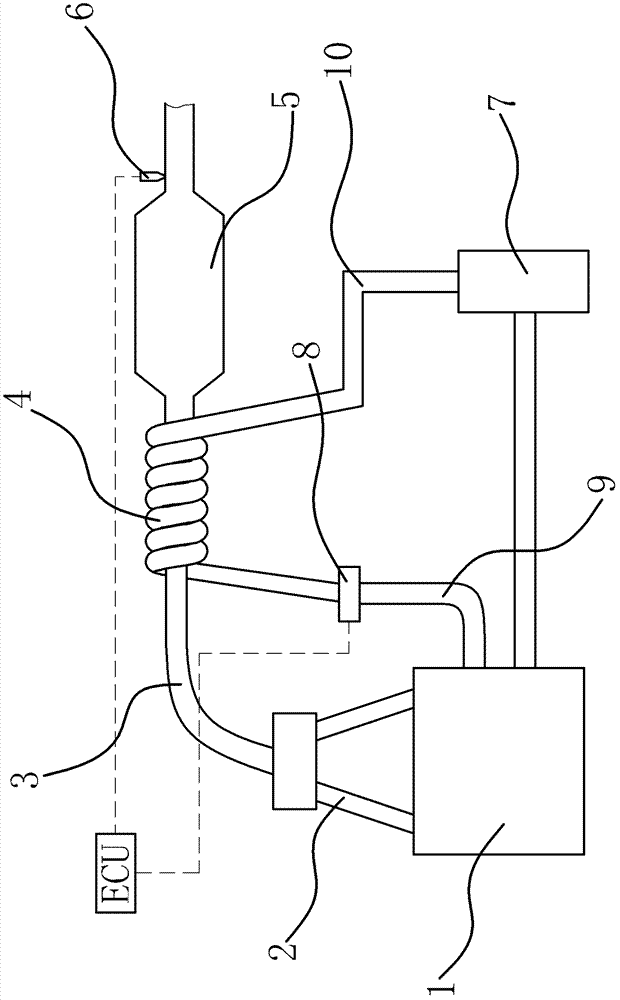

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0031] like figure 1 As shown, the automotive three-way catalytic reactor protection system includes ECU, sensing element, radiator 7 and other components, cooling device and control mechanism.

[0032]Specifically, the automobile includes an engine 1 , an exhaust pipe 3 communicating with the exhaust manifold 2 of the engine 1 and a three-way catalytic reactor 5 connected to the exhaust pipe 3 . In order to reduce the temperature of automobile exhaust, make the three-way catalytic reactor 5 work in the optimum temperature range, to achieve the best catalytic effect, and prevent the high-temperature exhaust gas from causing damage to the three-way catalytic reactor 5. The exhaust pipe 3 between the manifold 2 and the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com