Oil-filled temperature and pressure combined sensor

A composite sensor, temperature and pressure technology, used in instruments, measuring devices, etc., can solve the problem of temperature and pressure composite sensors unable to measure signals, and achieve the effects of small size, high stability and reliability, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

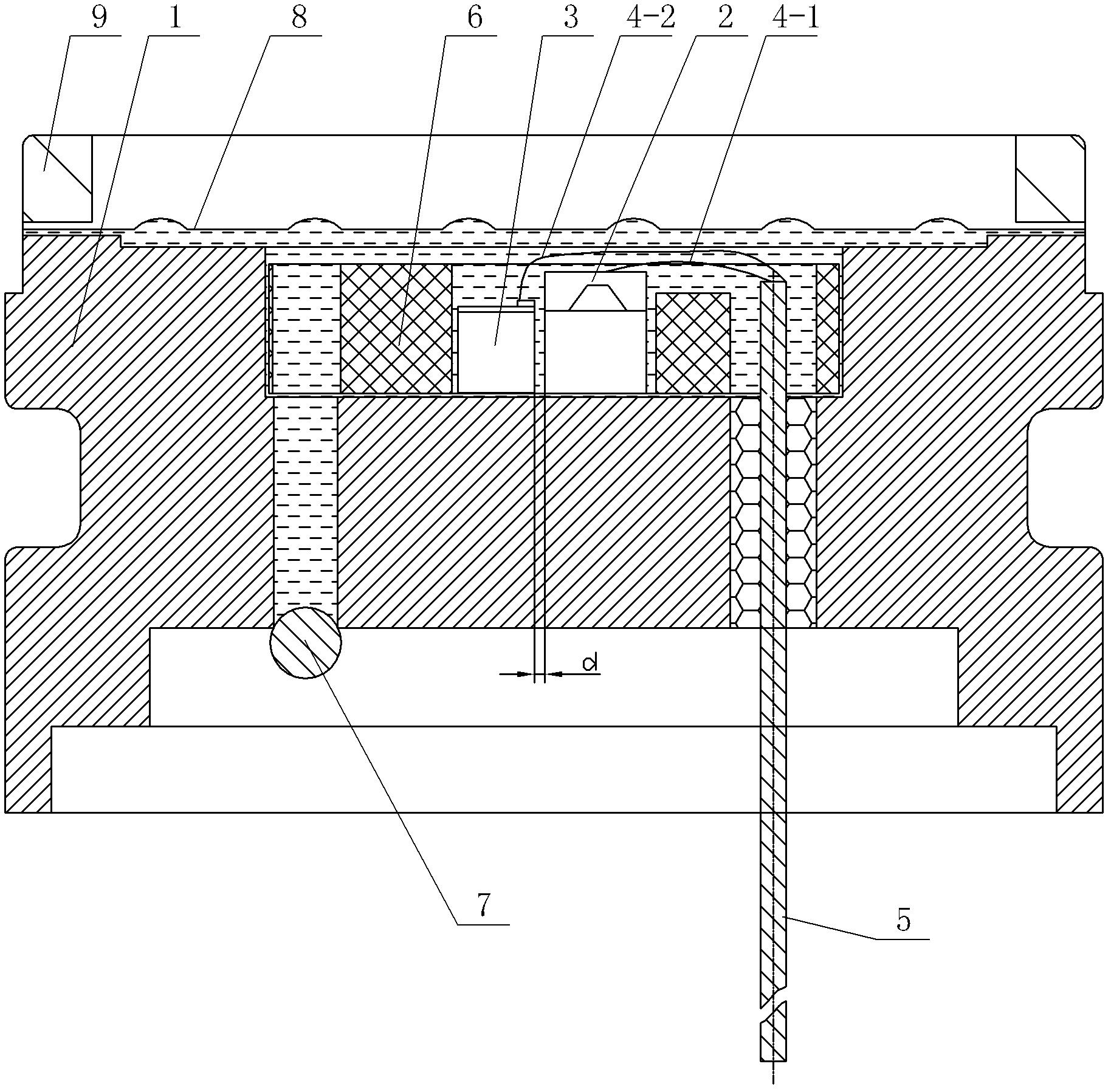

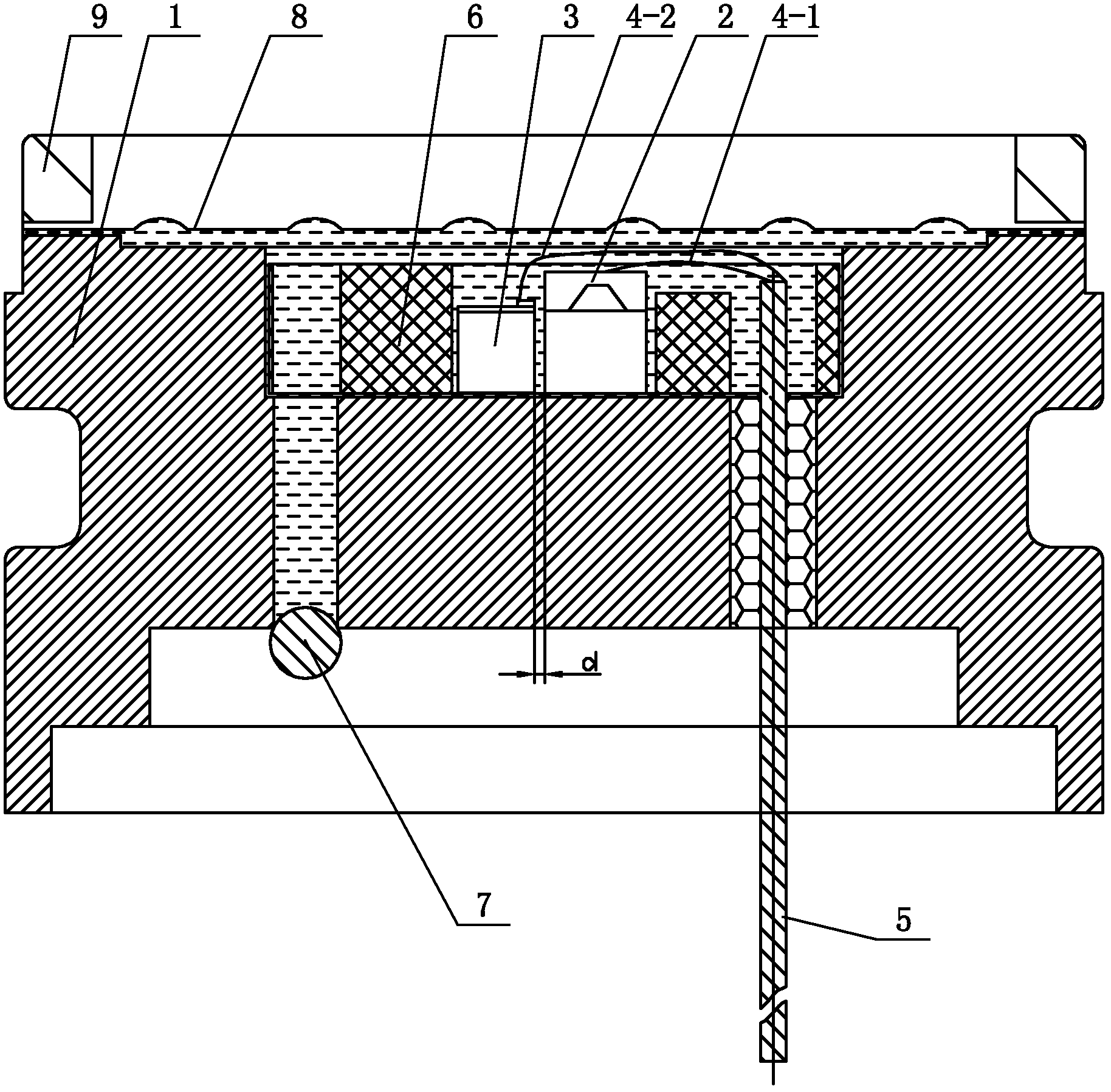

[0013] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the oil-filled temperature and pressure composite sensor described in this embodiment, it is made up of tube base 1, pressure chip 2, temperature chip 3, gold wire lead wire 4-1, silver palladium wire 4-2, externally drawn wiring harness 5. Composed of ceramic ring 6, sealing plug 7, corrugated diaphragm 8 and pressure ring 9,

[0014] The tube base 1 is a rotating body, the center of the upper surface of the tube base 1 has a circular groove, and the bottom of the circular groove is provided with an oil injection hole and an outer lead hole, both of which are close to the groove wall of the circular groove , the bottom end of the oil injection hole is provided with a plug 7,

[0015] The pressure chip 2 and the temperature chip 3 are eutectically welded in the circular groove of the tube base 1, the distance between the adjacent surfaces of the pressure chip 2 and the temper...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is a further description of Embodiment 1, and the range of d is 0.5mm-2mm.

[0024] The pressure chip 2 and the temperature chip 3 are designed with a reasonable distance, eutectic welding is welded into the tube base 1, the corrugated diaphragm 8 is welded to the upper end surface of the tube base 1 by argon arc welding, and the tube is filled with vacuum oil. Filling oil is injected into the seat 1, and the filling oil can be silicone oil. After the oil filling is completed, the oil injection hole is blocked, that is, the production of the oil-filled temperature and pressure composite sensor is completed.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The pressure chip 2 is composed of an SOI substrate, four single crystal silicon pressure sensitive resistors and SiO 2 Layer composition, four monocrystalline silicon pressure sensitive resistors and SOI substrate through SiO 2 layer isolation.

[0026] In this embodiment, the pressure chip 2 uses the SOI sheet as the substrate material, and uses the upper layer of single crystal silicon as the force-sensitive resistor material, and passes SiO2 between the resistor and the substrate. 2 Layer isolation removes the P-N isolation junction in the traditional diffused silicon piezoresistive sensor, so it has good high and low temperature stability, and is sealed with 7740 glass through electrostatic bonding to form a pressure sensitive chip.

[0027] The four monocrystalline silicon pressure-sensitive resistors are all standard Pt1000 resistors, and the external dimensions are 2×4.

[0028] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com