Regulation system and method for closed storage environment

A control system and warehousing technology, which is applied in the direction of anti-rot containers, transport buses, tank cars, etc., can solve the problems of limited dry and wet adjustment ability, environmental pollution, poor gas adjustment ability, etc., to achieve thorough response, improve storage environment, improve The effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

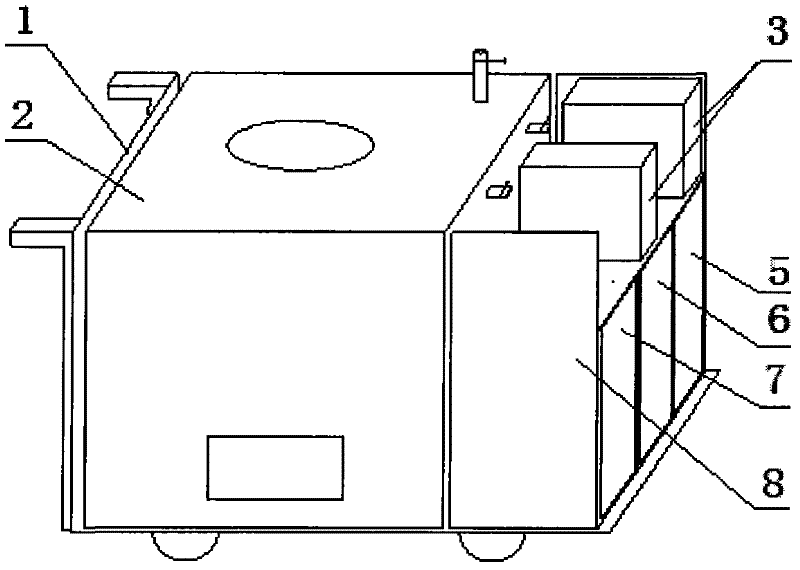

[0051] Such as figure 1 , 3 As shown, a control system for a closed storage environment includes a walking device 1, a gas generating device 2, a humidity regulating device 3, an airtight device 4, a power supply device 5, an air extraction / blowing device 6, a condensation water device 7, and a structure device 8. Sterilizing filter device 12.

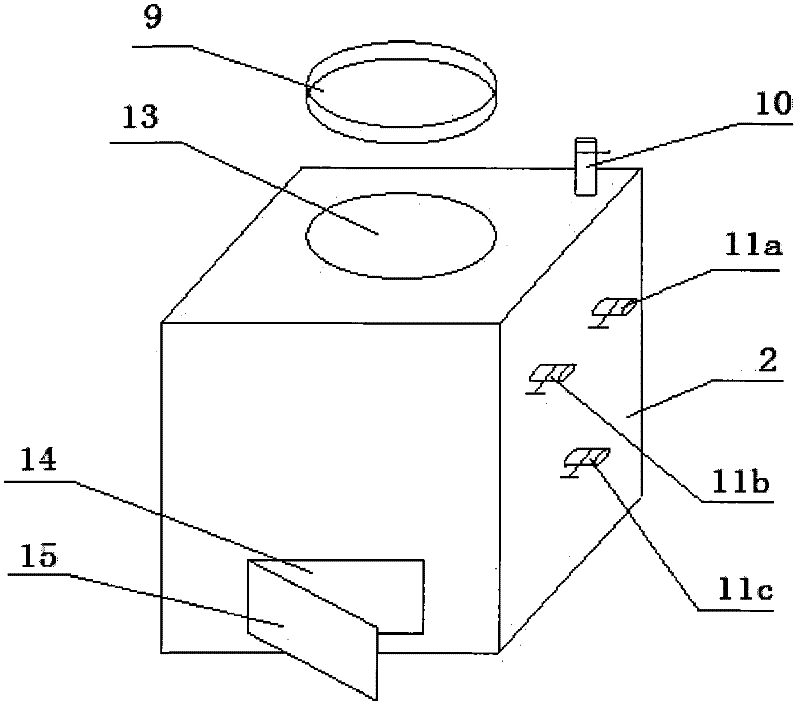

[0052] Such as figure 2 As shown, the gas generating device 2 is a box made of stainless steel, and its size is 1.4m by 1m by 1m. On the upper surface of the gas generating device 2, a feeding port 13 and a feeding port cover 9 are arranged. Through the feeding port 13 Put storage atmosphere regulators. On the surface where the feeding port 13 is located, an air outlet 10 is also provided. On the side bottom position of the gas generating device 2, a slag discharge port 14 is provided and a slag discharge port door 15 is installed. After the reaction of the storage atmosphere regulator is completed, the slag discharge port is opene...

Embodiment 2

[0060] When dehumidifying the closed environment of stored goods, the control system of the closed storage environment adopted is the same as that in Embodiment 1.

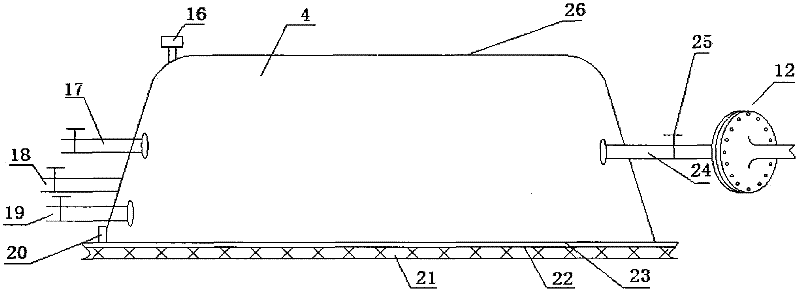

[0061] Firstly, the stored goods are placed in the sealing device 4 , and the bottom cover 23 and the top cover 26 of the sealing device 4 are sealed through the sealing slot 20 . Then, if Figure 9 As shown, a control system for a closed storage environment is constructed. Connect the air inlet of the exhaust fan to the air outlet 18 of the airtight device 4, close the other air outlets and air inlets, turn on the exhaust fan, and extract the air in the airtight device 4 until the top cover is close to the storage, stop the ventilation, and close the Air outlet 18 valves; connect the air outlet of the rotary dehumidifier with the air inlet 11a of the gas generating device 2, connect the condensed water pipe of the dehumidifier to the condensed water collector 34 through the condensed water conduit inlet 32, and ...

Embodiment 3

[0063] When humidifying the closed environment of stored goods, the control system of the closed storage environment adopted is the same as that in Embodiment 1.

[0064] Firstly, the stored goods are placed in the above-mentioned sealing device 4 , and the bottom cover 23 and the top cover 26 of the sealing device 4 are sealed through the sealing groove 20 . Then, if Figure 10 As shown, a control system for a closed storage environment is constructed. The air outlet of the humidifier is connected with the air inlet 11a of the gas generator 2, the air outlet of the blower is connected with the air inlet 11c of the gas generator 2, and the air outlet 10 of the gas generator 2 is connected with the sterilizing filter device 12 Connect the air inlet 30 of the sterilizing filter device 12 with the air inlet 24 of the airtight device 4, connect the blower air inlet with the air outlet 19 of the airtight device 4, and close the air intake of the gas generating device 2 Port 11b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com